Cleaning vane wheel and unpowered locomotive radiator automatic heat dissipation cleaning device

A technology for radiators and impellers, which is applied in the cooling of engine components, machines/engines, and engines. It can solve problems such as high cleaning frequency, affecting air intake, and small filter meshes, achieving high cleaning efficiency and large cleaning area. , the effect of high brush density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

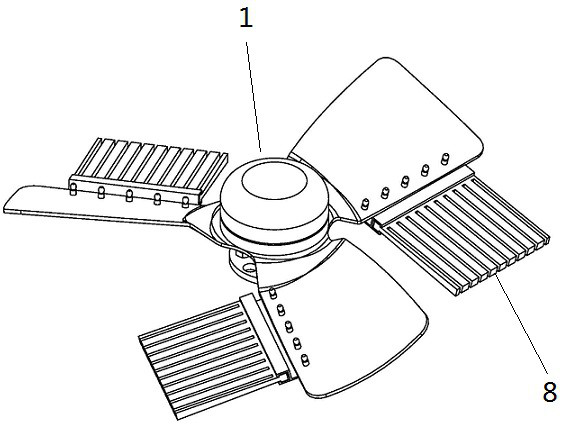

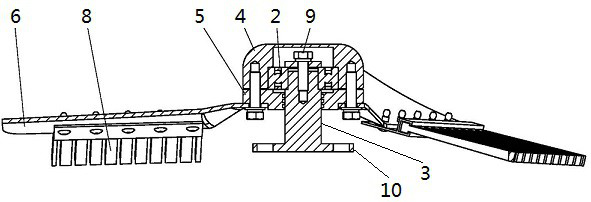

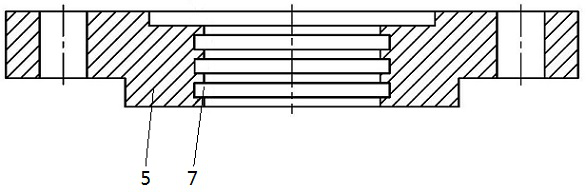

[0024] A cleaning impeller, comprising an impeller 1, characterized in that: a strip brush 8, a bearing 2, a support shaft 3 and a fixed seat 10 are provided, and the blade 6 of the impeller 1 is provided with a strip brush 8, and the strip brush 8 and the The blade 6 is fixedly connected, one end of the support shaft 3 is fixedly connected to the impeller 1 through the bearing 2, and the other end is fixedly connected to the fixed seat 10, and the fixed seat 10 is provided with a mounting hole, so that when the natural wind blows to the blade, The blade rotates, and the strip brush rotates accordingly, which can play a role in wiping and cleaning. At the same time, the rotation of the blade generates airflow, which accelerates the air flow and quickly dissipates heat.

[0025] The strip brush 8 of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com