A metal ingot casting production line

A casting production line and metal ingot technology, which is applied in the field of metal ingot casting production line, can solve problems such as hidden safety hazards, unsightly appearance, energy waste, etc., and achieve the effects of saving energy, reducing hidden safety hazards, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

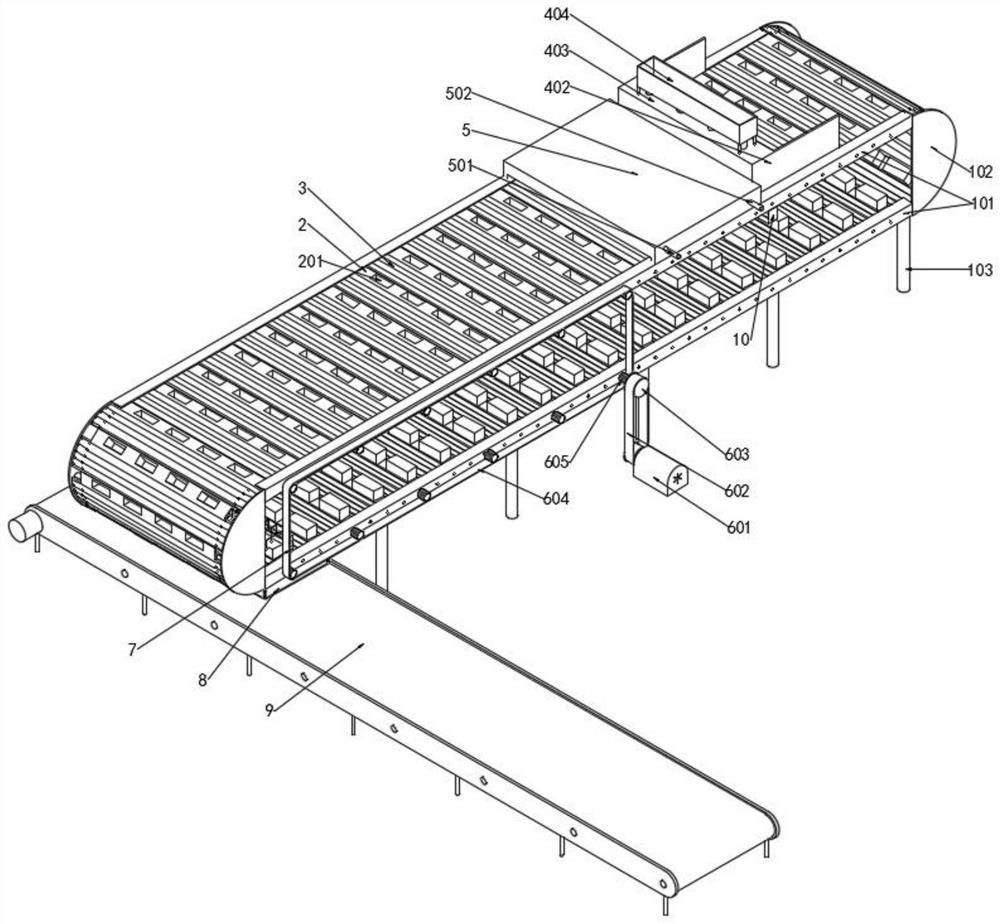

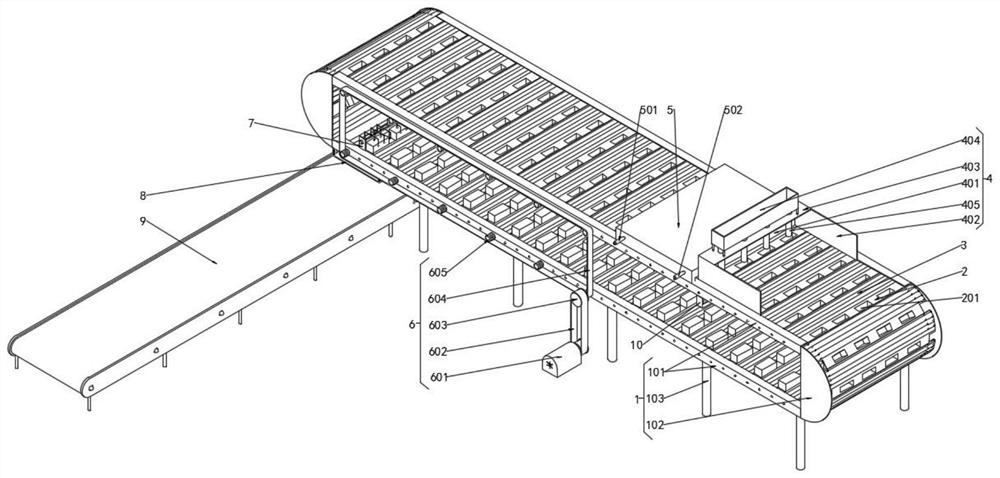

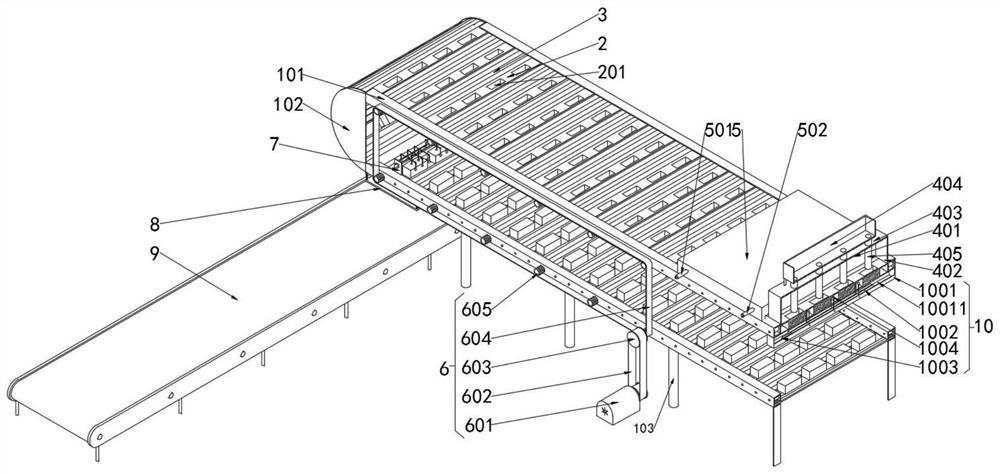

[0083] The accompanying drawing is the best embodiment of the metal ingot casting production line, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0084] attached by figure 1 to attach Figure 4 As shown, a metal ingot casting production line includes a frame 1 , a metal ingot casting plate 2 , a connecting plate 3 , a scraper box 4 , and a driving device 6 .

[0085] The frame 1 includes two symmetrically arranged upper and lower beams 101 , four first end plates 102 , and several support legs 103 fixedly connected to the bottom of the lower beam 101 . The four beams 101 form a rectangle, and the first end plate 102 is arranged between the upper and lower beams 101 and is fixedly connected to the ends of the two beams 101 . The two opposite first end plates 102 or supporting legs 103 are fixedly connected by reinforcing rods, so that the frame 1 forms a whole.

[0086] The inside of the first end plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com