Sealing structure for container and cover body

A sealing structure and container technology, applied in the directions of sealing, removable cover/cover, closing, etc., can solve the problems of cover falling off, container deformation, poor sealing, etc., to achieve the effect of stable bonding and maintaining tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

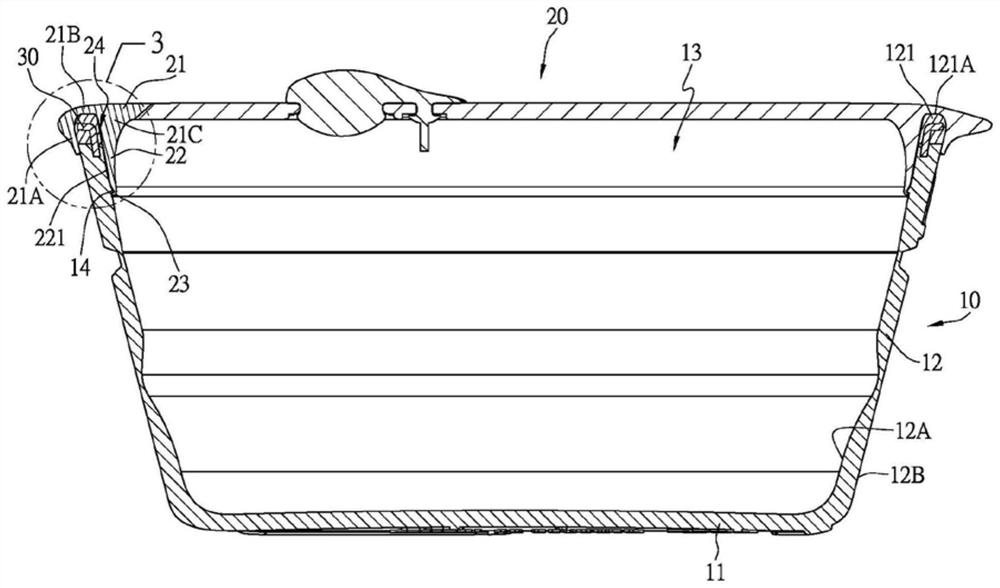

[0039] In the embodiment of the present invention, such as Figures 1 to 3 shown, where:

[0040] The cover part 21 has a first side section 21A, a top section 21B and a second side section 21C connected in sequence, the first side section 21A is closely attached to the outer surface 12B, the second side section 21C is closely attached to the inner surface 12A, Then a fastening force is generated, and the covering surface 211 is located on the top section 21B.

[0041] The cover body 20 has an attachment portion 22, the attachment portion 22 is connected to the second side section 21C, the attachment portion 22 has an attachment surface 221, the attachment surface 221 faces the inner surface 12A of the side wall 12, and the second hook portion 23 Connect the attached part 22;

[0042] As a result, the sticking surface 221 is attached to or separated from the inner surface 12A according to pressure changes in the container 10 .

[0043] Preferably, the distance between the f...

Embodiment 2

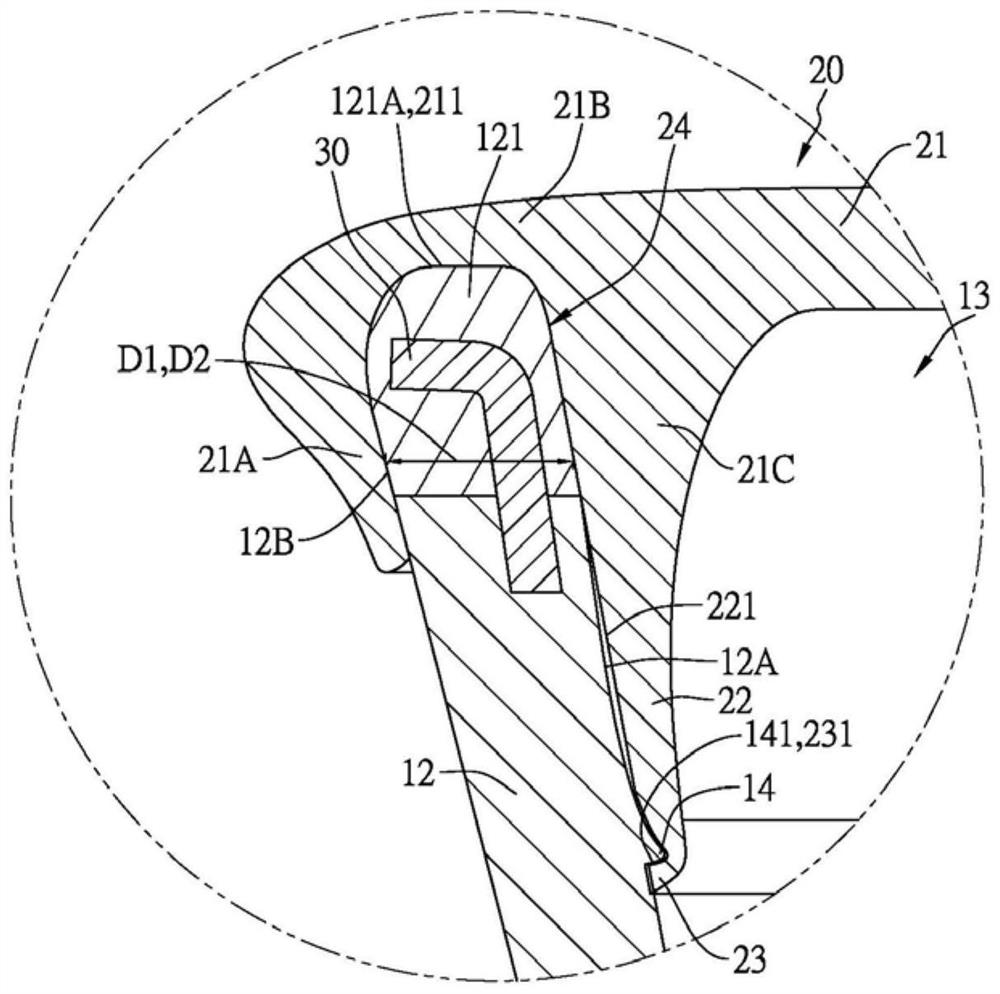

[0046] In the embodiment of the present invention, such as Figure 4 shown, where:

[0047] The cover part 21 has a first side section 21A, a top section 21B and a second side section 21C connected in sequence, the first side section 21A is closely attached to the outer surface 12B, the second side section 21C is closely attached to the inner surface 12A, Then a fastening force is generated, the covering surface 211 is located on the top section 21B, and the second hook portion 23 is connected to the second side section 21C.

[0048] Preferably, the distance between the first side section 21A and the second side section 21C is the first distance D1, the width of the side wall 12 has the second distance D2, and the distance between the first side section 21A and the second side section 21C is The insertion space 24, when the cover body 20 is set in front of the container 10, that is, the opening end 121 is arranged in front of the insertion space 24, the first distance D1 is s...

Embodiment 3

[0050] In the embodiment of the present invention, such as Figure 5 shown, where:

[0051] The covering portion 21 has a top section 21B and a second side section 21C connected in sequence. The second side section 21C is closely attached to the inner surface 12A to generate a fastening force. The covering surface 211 is located on the top section 21B.

[0052] The cover body 20 has an attachment portion 22, the attachment portion 22 is connected to the second side section 21C, the attachment portion 22 has an attachment surface 221, the attachment surface 221 faces the inner surface 12A of the side wall 12, and the second hook portion 23 Attach the attachment part 22.

[0053] As a result, the sticking surface 221 is attached to or separated from the inner surface 12A according to pressure changes in the container 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com