Carton turnover mechanism

A technology of overturning mechanism and carton, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc. It can solve the problems of time-consuming and labor-intensive, and achieve the effect of wide application range, reasonable structure design and strong operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

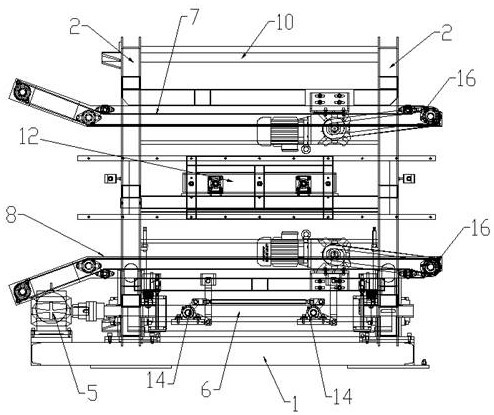

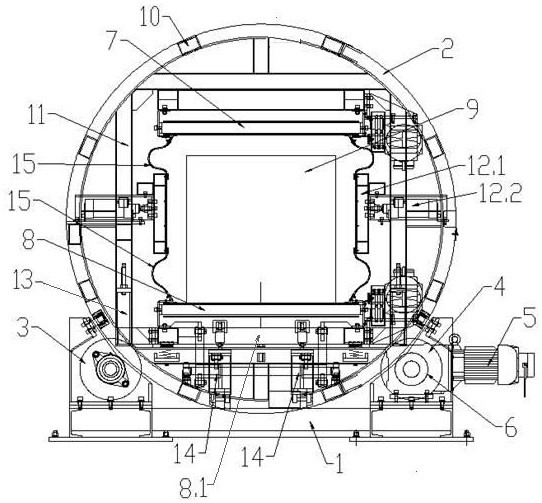

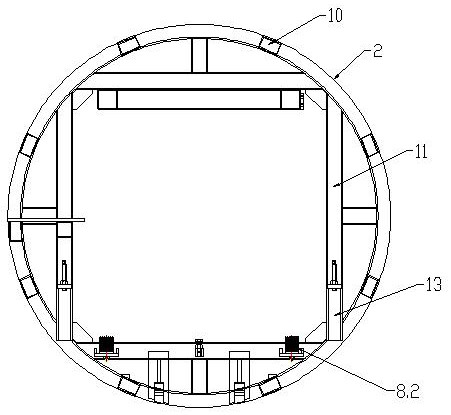

[0021] Now in conjunction with accompanying drawing, the present invention will be further elaborated. The parts not specifically stated below are all carried out according to the conventional technology of the tobacco industry. (In the following, the orientation is determined based on the conveying direction of the conveying mechanism, wherein "front" refers to the direction in which the carton enters the conveying mechanism, and "rear" refers to the direction in which the carton will leave the conveying mechanism).

[0022] Such as figure 1 As shown, the carton turning mechanism of the present invention includes a turning mechanism fixed on the base 1, a conveying mechanism, and a carton. The overturning mechanism includes two linkage ring gears 2, two balance support gears 3, two drive gears 4, and a main drive motor 5, in which the two linkage ring gears 2 are outer gear rings, and each linkage ring gear 2 passes through There is a driving gear 4 meshed with the teeth, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com