A crane tube loading metering system

A metering system and crane tube technology, applied in the field of crane tube loading metering system, can solve the problems of cumbersome measurement process, accuracy error of flowmeter, affecting the accuracy of loading oil quantity, etc., and achieve accurate control and precise quantitative loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

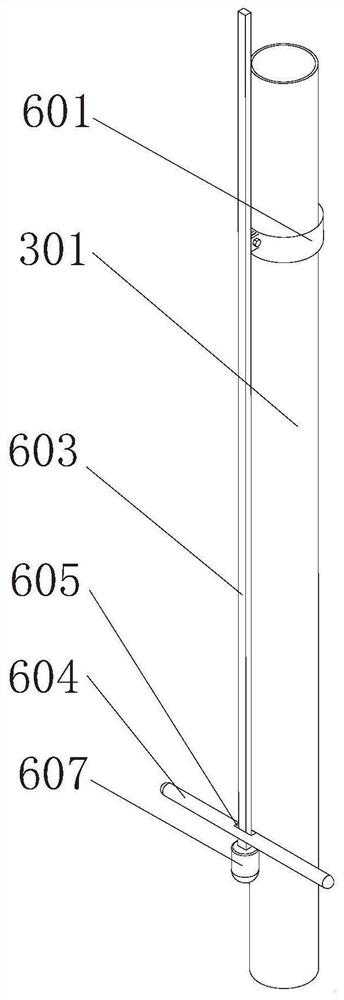

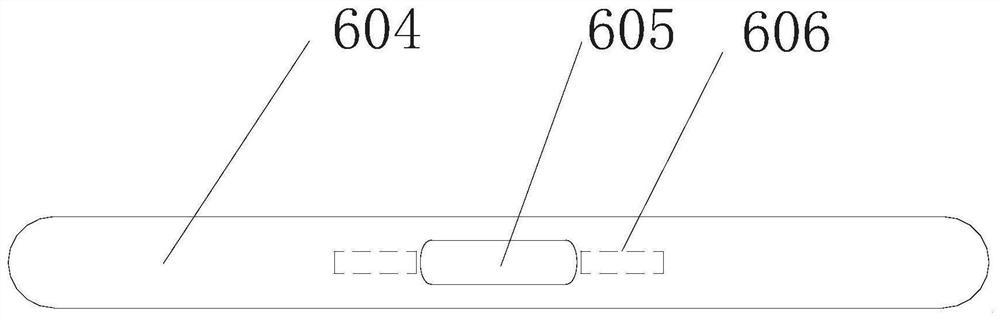

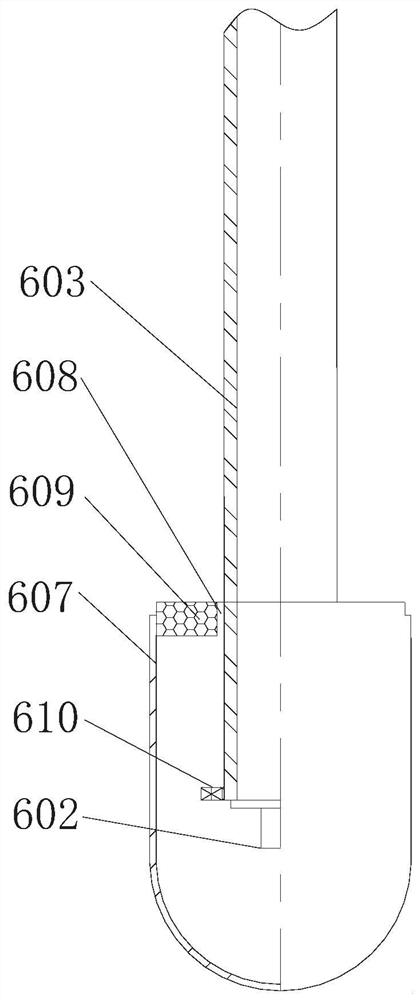

[0030] Such as Figure 1 to 5 As shown, a crane-loaded metering system includes a vertical pipe 301, an oil pump, a flow meter, and a controller, including a rod 603 disposed vertically at the outer circumference of the vertical pipe 301, which is sleeved on the tabs 604 on the rod 603. The electronic bin is disposed at the top of the measurement rod 603 and the float 606 provided on the bottom end of the rod 603, and the tab 604 is provided with a small magnet 606 close to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com