Track lifting and lining device and track lifting and lining operation method

A technology for lifting and operating the track, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problems of uncompact structure and complicated operation of the track lifting device, and achieve the effect of compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

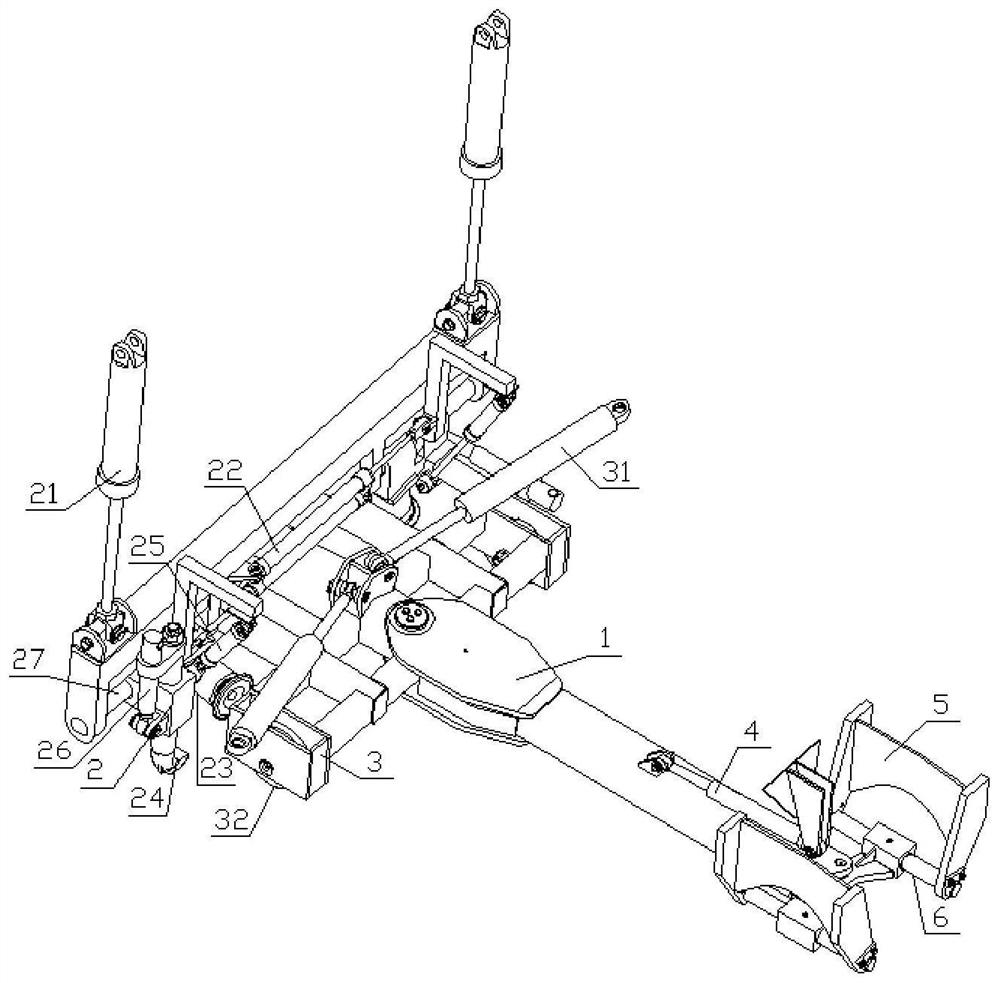

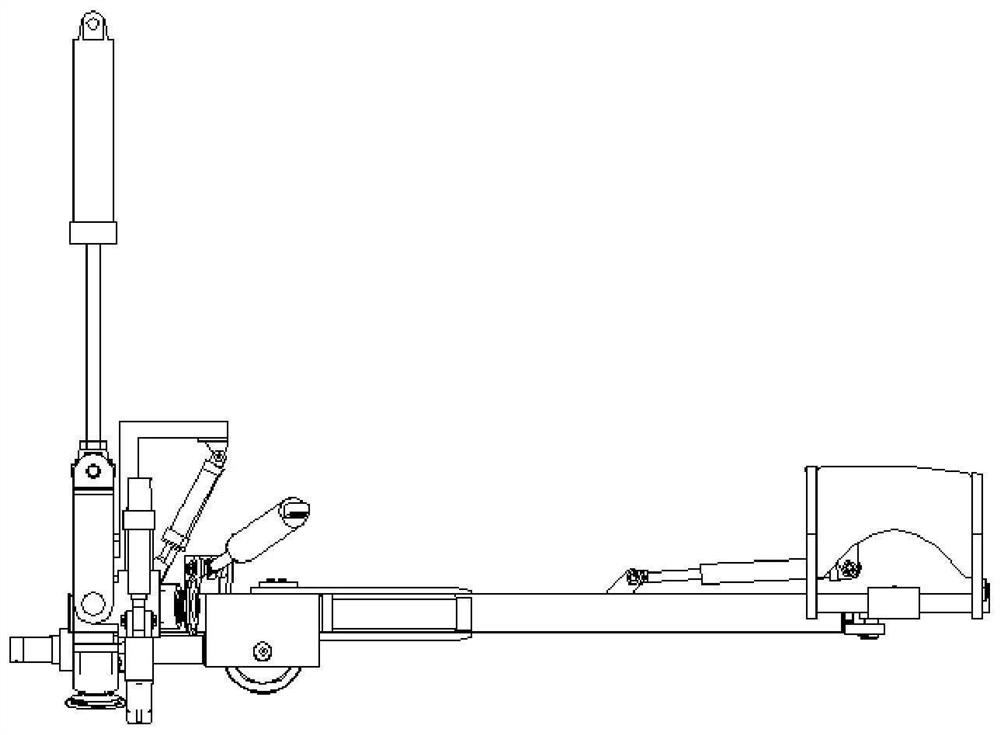

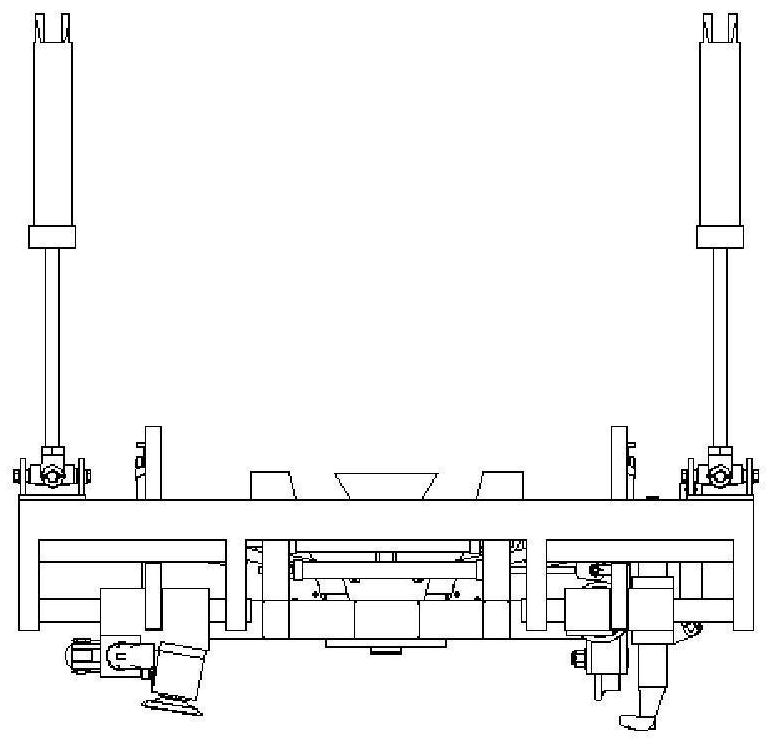

[0043] Embodiment 1.1: a kind of dialing track device, such as Figure 1 to Figure 4 The structure of the pulling device is given. The track opening device in this embodiment includes a track opening frame 1 , a track opening device 2 , a track opening device 3 , a track opening position adjustment mechanism 4 , and a frame mounting seat 5 . One end of the frame mounting seat 5 is connected to the road maintenance machine body, and the other end is equipped with a guide column 6, which is nested and connected to the track opening frame 1, and the track position adjustment is connected between the track opening frame and the frame mounting seat 5 Mechanism 4, under the action of the track position adjustment mechanism 4, makes the entire track frame 1 move along the guide column 6, thereby realizing the displacement adjustment of the track position along the X direction, and the track frame 1 is connected to the track device 3 and the track lifting device 2, the track pulling ...

Embodiment 21

[0054] Embodiment 2.1: a kind of operation method of dialing road:

[0055] 1: Place the lifting track device on the line rail where the lifting operation is required;

[0056] 2: Enable the lifting switch structure to hook the lifting wheel or the lifting hook to the rail, that is, use the lifting hook at the joint of the rail and other places where the lifting wheel cannot be used to hook the rail, and use the lifting wheel at other positions;

[0057] 3: Activate the track-lifting drive mechanism to lift the track-setting device, and perform the track-lifting operation through the track-lifting wheel or the track-lifting hook. At the same time, enable the track-setting drive mechanism to move the track-setting device laterally, and perform the track-setting operation through the track-setting wheel ;

[0058] 4: Continue to carry out the routing operation on the line until the workload is completed.

Embodiment 22

[0059] Embodiment 2.2: a kind of operation method of dialing road:

[0060] 1: Place the lifting track device on the line rail where the lifting operation is required;

[0061] 1.1: Enable the track position adjustment mechanism 4 to adjust the track frame 1 to the area where the track wheel 23 or the track hook 24 and the track wheel 32 can work.

[0062] 2: Enable the lifting switch structure 25 to hook the lifting wheel 23 or the lifting hook 24 to the rail, use the lifting hook 24 at the joint of the rail, etc. where the lifting wheel 23 cannot be used to hook the rail, and use the lifting wheel at other positions twenty three;

[0063] 3: Enable the lifting drive mechanism 21 to lift the lifting device, and carry out the lifting operation through the lifting wheel 23 or the lifting hook 24. 32. Carry out channel assignment;

[0064] 4: Continue to carry out the routing operation on the line until the workload is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com