Lifting lug fixing device for crane

A technology for fixing devices and cranes, which is applied in the field of hoisting machinery, can solve the problems of increasing the production cost of machine rooms, and achieve the effects of saving working space, simple structure, and reducing materials and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

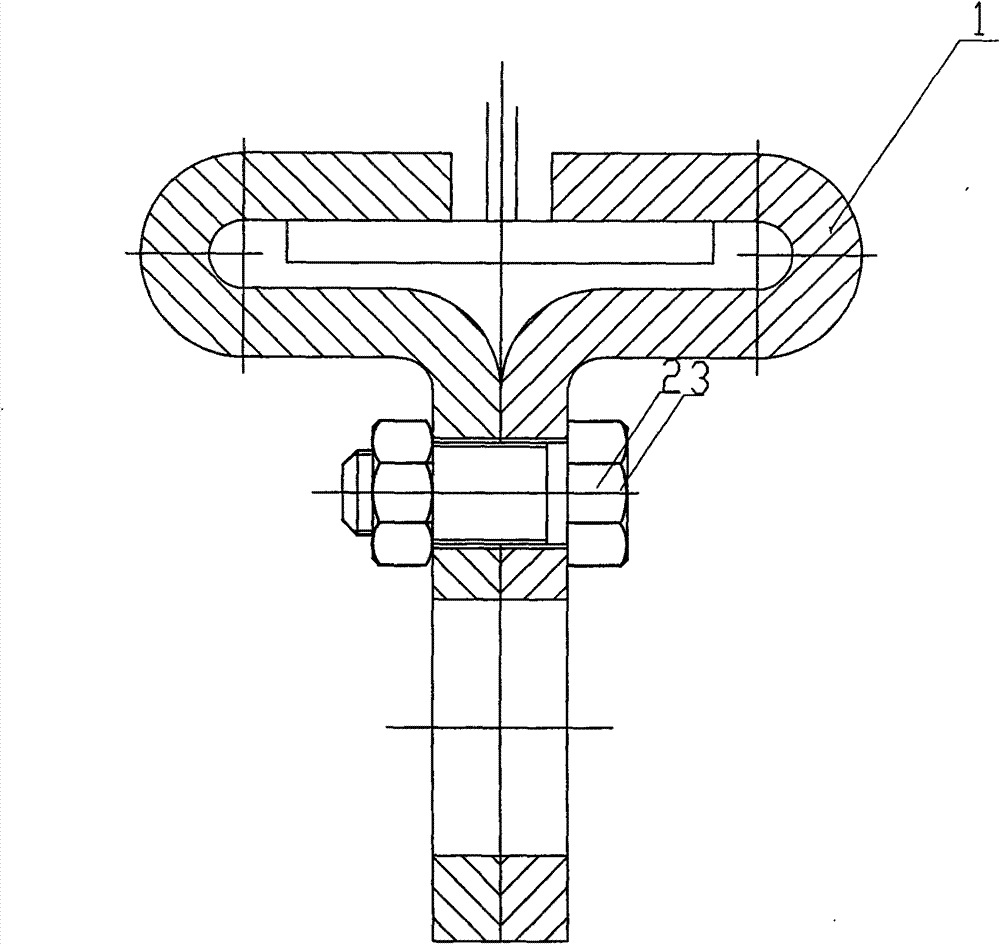

[0009] Such as figure 1 As shown, it includes special-shaped steel plates 1, bolts 2, and nuts 3.

[0010] In the lifting operation of the present invention, the grooves of the two special-shaped steel plates 1 are placed on the lower end surface of the I-shaped keel steel frame in the machine room, and then the bolts 2 are inserted into the upper holes of the special-shaped steel plates 1 to calibrate their meshing flatness , screw in nut 3 and tighten. This fixing device promptly has been installed, as long as ready-made chain hoist is assisted with shackle to be fixed in the bottom hole of special-shaped steel plate 1 after this, can implement hoisting operation. During operation, the present invention can be slid to a specified position at any time according to needs. When not in use, you only need to remove the shackle and bolts to place it any...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com