Construction method of asymmetric overall lifting of large grid structure

A technology of grid structure and construction method, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of harsh welding environment conditions, high safety hazards, and difficult safety protection, and achieve safe and reliable construction process. The effect of saving construction cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] An embodiment of the lifting construction of a large-scale grid structure related to super high-altitude asymmetric support according to the present invention includes the following steps:

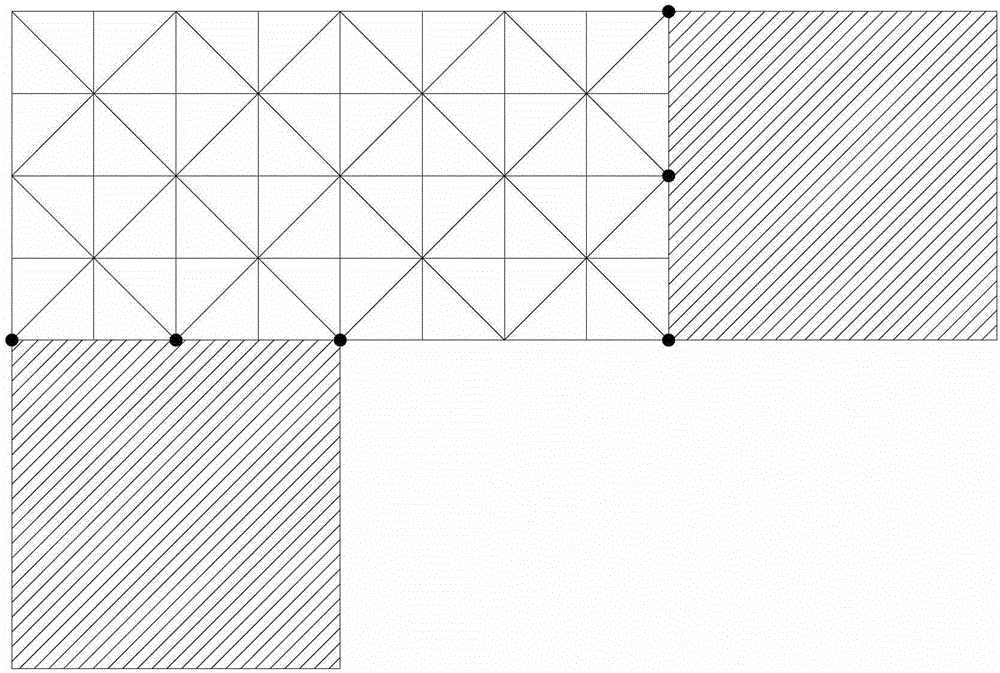

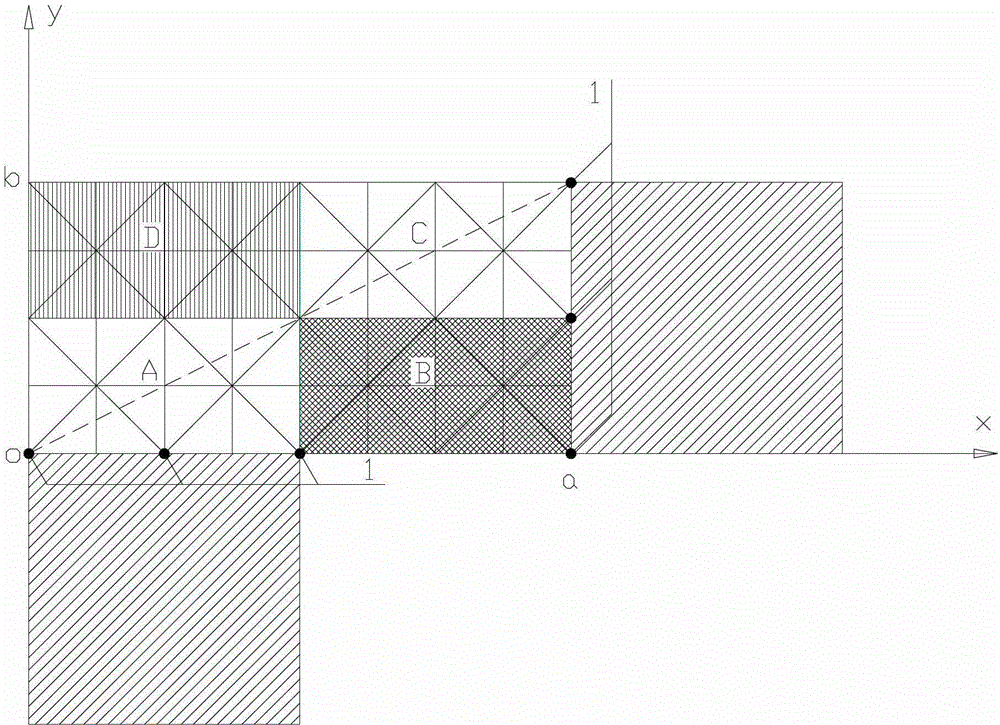

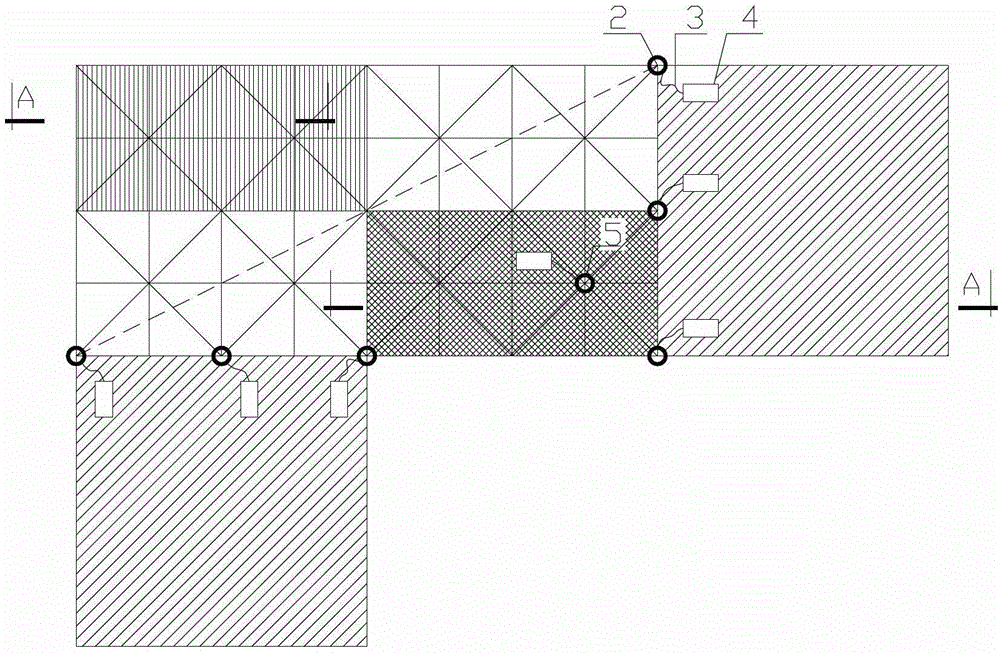

[0030] (1) Determine the location of the lifting points of the asymmetrically supported grid structure. figure 1 It is a schematic diagram of the layout of a typical asymmetric braced grid structure. First of all, a reasonable lifting point layout position should be determined according to the mutual positional relationship between the asymmetrically supported large-scale grid structure and its lower supporting structure. The principle for determining the lifting point layout position is: a. The lifting point can envelop the plane area of the grid structure to the gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com