A prefabricated wall panel with an integrated green building extending to form a corner panel and its use method

A green building and prefabricated technology, which is applied in the processing of building materials, construction, building components, etc., can solve the problems of high transportation costs and high structural strength, and achieve the effects of low transportation requirements, improved structural strength, and increased joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

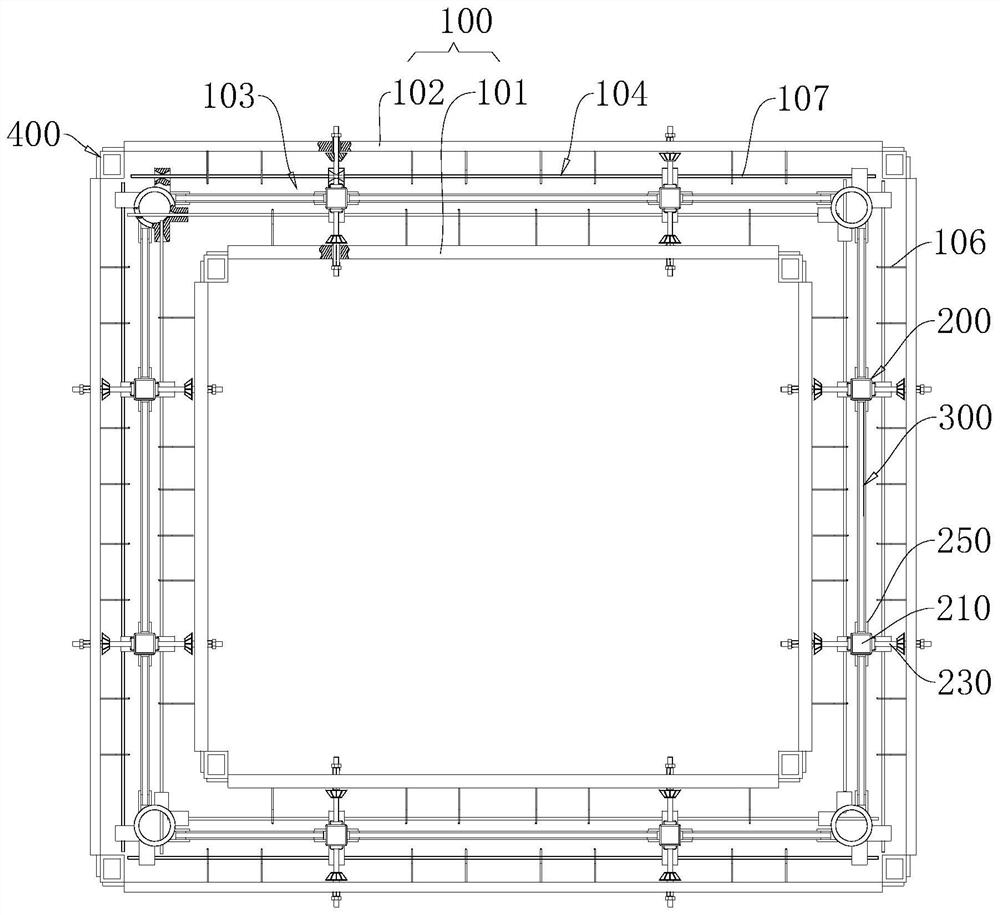

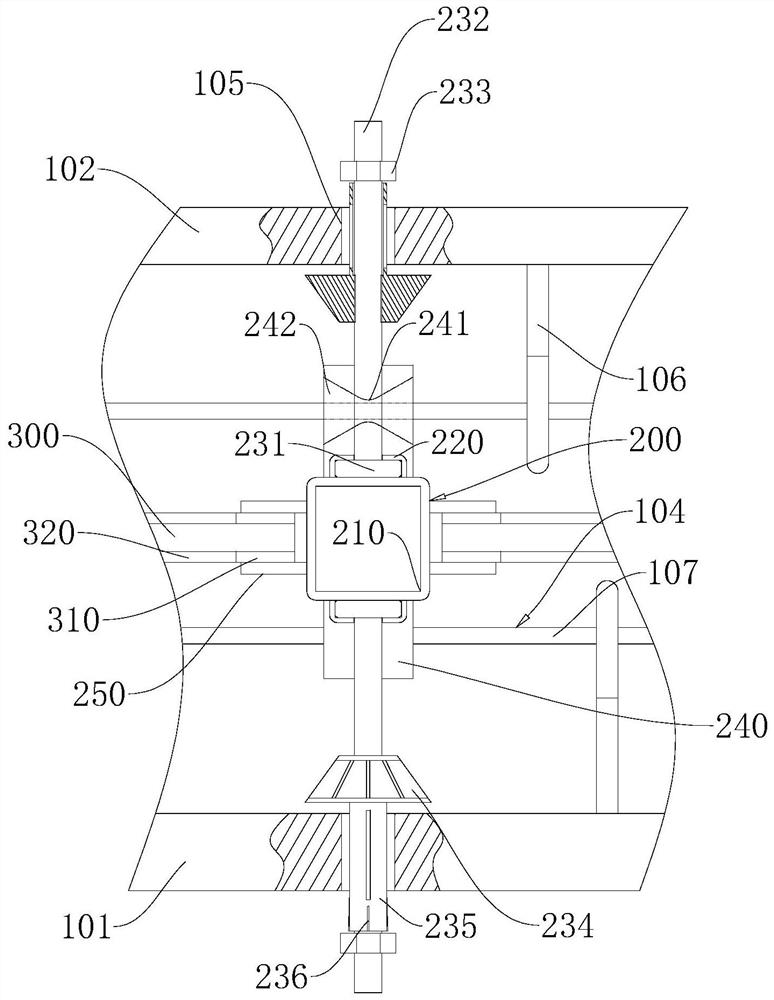

[0045] Embodiment 1: A kind of prefabricated wall panel with an extension to form a corner panel for green building integration, refer to figure 1 , which includes an inner wall panel 101 and an outer wall panel 102, a pouring gap 103 is left between the inner wall panel 101 and the outer wall panel 102, and a reinforcement mesh 104 is placed in the pouring gap 103, wherein the inner wall panel 101 and the outer wall panel 102 The outer wall panels 102 are light and thin prefabricated panels, which are directly used as templates to form a pouring space for pouring and molding. A fixing component 200 is arranged between the inner wall panel 101 and the outer wall panel 102 , and the reinforcement mesh 104 is fixed to the fixing component 200 . After the inner wall panel 101, the outer wall panel 102, and the reinforcement mesh 104 are fixed, concrete is filled into the pouring gap 103, and after curing, a complete structure is formed.

[0046] like figure 1 and figure 2 As ...

Embodiment 2

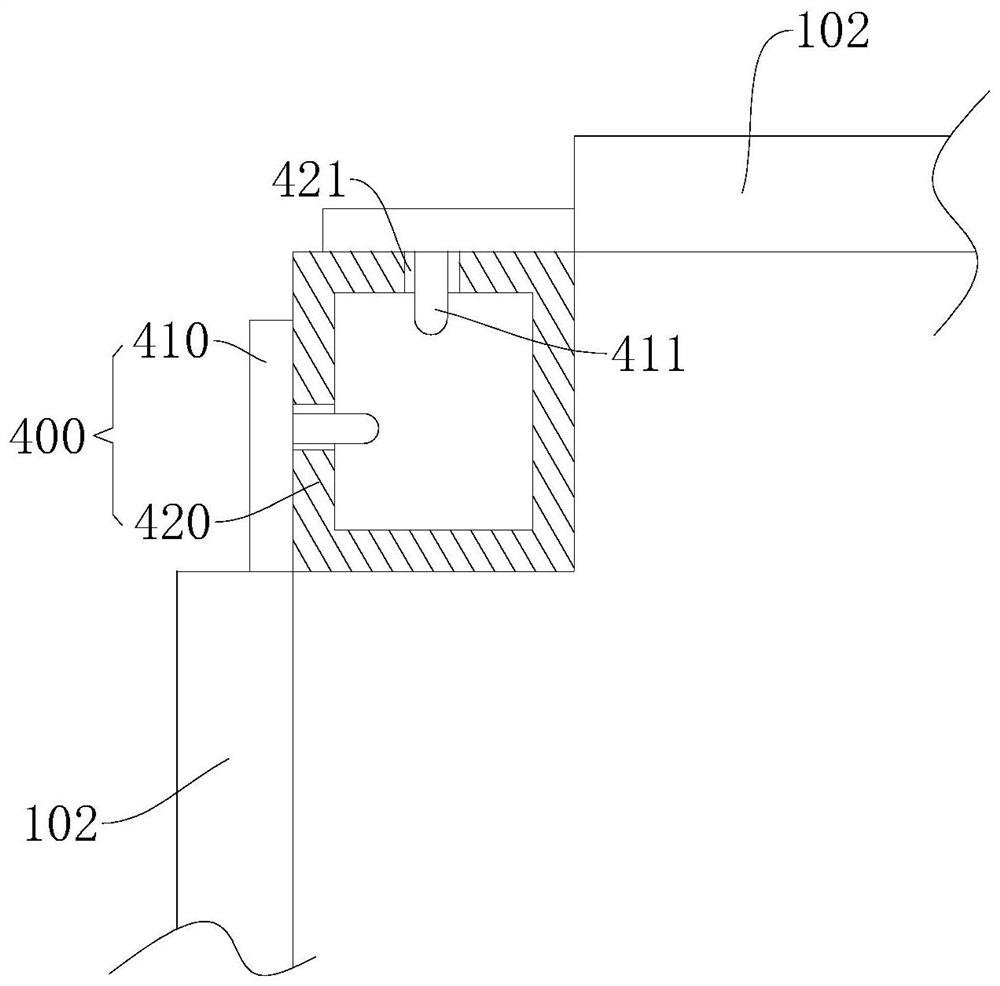

[0053] A prefabricated wall panel with an integrated green building extending to form a corner panel. Its structure is generally the same as that of Embodiment 1, except that the wall 100 connects the component 400 between the walls 100 . In actual use, there are various connection structures between the wall body 100 and the wall body 100 , including horizontal butt joint and certain angle butt joint. At this time, the square pipe connection mechanism of the joint member 420 can be replaced. In conjunction with the accompanying drawings of Embodiment 1, and with reference to Figure 4 and Figure 5 , Image 6 It is a schematic diagram of a horizontal docking structure. The docking piece 420 includes a first docking plate 422 and a second docking plate 423. The first docking plate 422 and the second docking plate 423 are integrated. Connecting holes 421 are respectively provided, and the connecting hooks 411 are fastened through the connecting holes 421 . The first butt pla...

Embodiment 3

[0055] A prefabricated wall panel with an integrated green building extending to form a corner panel. Its structure is generally the same as that of Embodiment 1, the difference lies in the installation of the insulation board 300 when the wall 100 is docked with the wall 100 . In conjunction with the accompanying drawings of Embodiment 1, and with reference to Figure 7 , in the process of horizontal docking, its structure does not change, which mainly lies in the structural adjustment of the docking position of the wall 100 at the corner position. A corner post 260 is set at the corner of the wall body 100 and the wall body 100. The corner post 260 has the same structure as the hollow post 210. The corner post 260 is also provided with a fixing head 240 for piercing the steel bar 107, and the corner post 260 The connecting groove 220 is also arranged on the top, and the corner column 260 can be set as a hollow tube. The connecting groove 220 on the corner column 260 correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com