Automatic separation of oil and water inflow controller

An automatic separation and controller technology, applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of high tool cost, difficult water blocking operation, accelerated water content rise, etc., and achieve the effect of convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

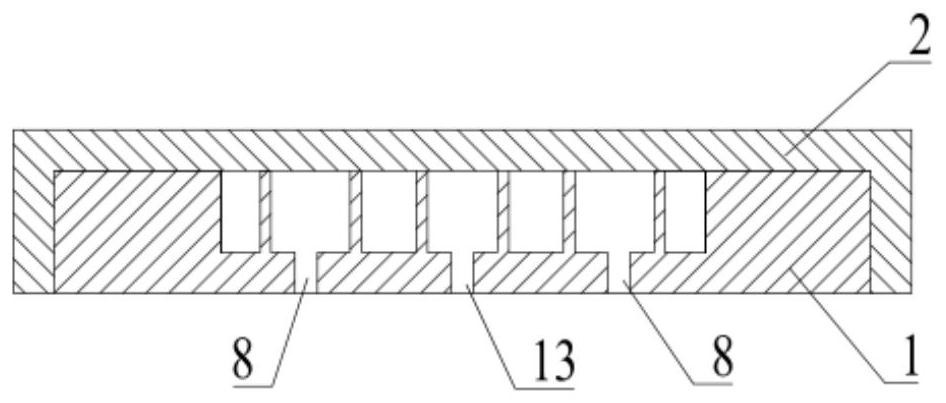

[0019] Such as figure 1 As shown, an oil-water automatic separation inflow controller is composed of a valve base 1 and a valve cover 2, and the valve base 1 and the valve cover 2 are connected by thread sealing.

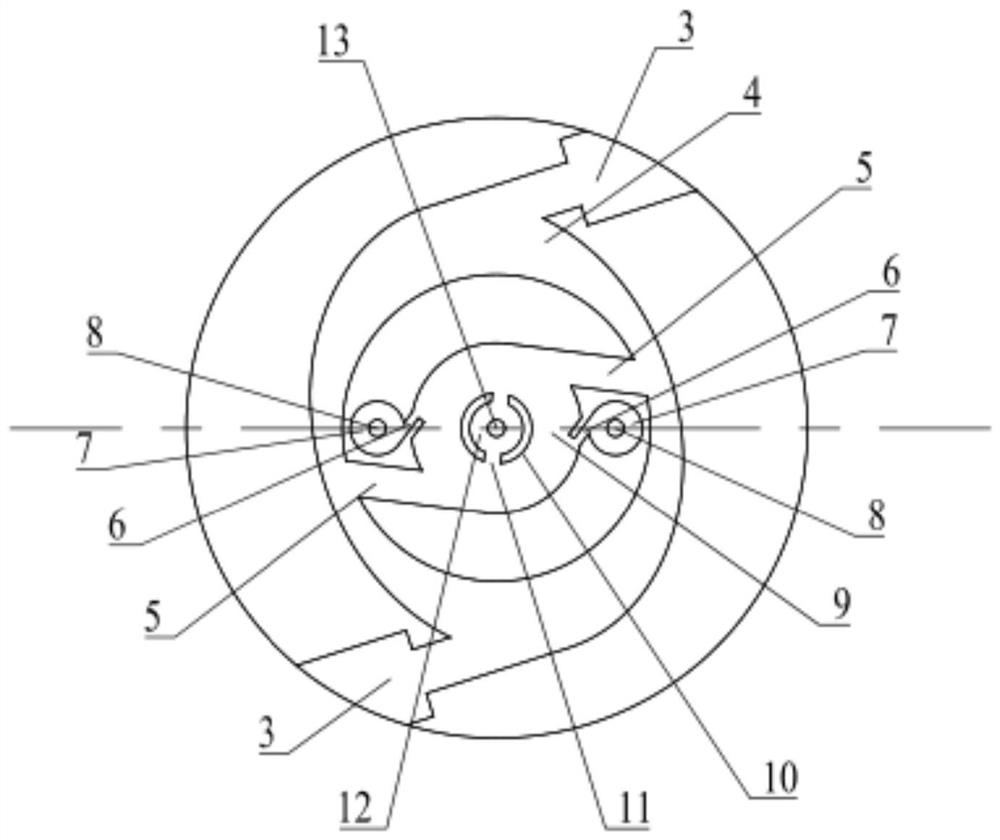

[0020] Such as figure 2 As shown, the working process of the present invention is as follows. The fluid passes through the inflow channel 3, and the speed increases when passing through the sudden contraction of the flow channel section, and then enters the accelerated swirl chamber 4 tangentially, and the fluid flow rate increases and then passes through the internal diversion groove 5 Entering the cyclone separation chamber 9 tangentially, the fluid rotates and flows. Due to the low viscosity of the water, its inertial force is large, and it flows along the wall of the cyclone separation chamber 9, and then the water enters the water cyclone chamber 7 ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com