Production site structure for solving spinning and winding airflow countercurrent

A kind of ground structure and spinning technology, applied in application, household heating, household appliances, etc., can solve the problems of air pressure imbalance, waste of production energy, inability to cover, etc., to ensure stable transportation, improve tow quality, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

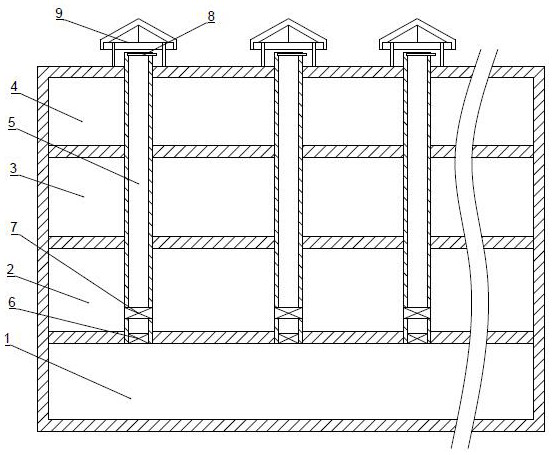

[0020] Such as figure 1 As shown, this embodiment describes a production site structure that solves the countercurrent flow of spinning and winding air. The site structure includes an auxiliary equipment floor 4, a melt pipeline floor 3, a spinning floor 2 and a winding floor 1, and consists of From bottom to top, there are winding floor 1, spinning floor 2, melt pipeline floor 3 and auxiliary equipment floor 4. Several air ducts 5 are arranged on the top of winding floor 1, and air ducts 5 are arranged vertically upward and extend to the site Above the top of the structure, there is no connection between the air duct 5 and the spinning floor 2 .

[0021] An air volume control valve 6 is arranged on the air pipe 5; a fire damper 7 is arranged inside the air pipe 5 within the scope of the spinning floor 2; a canopy 9 and a pull-out sealing plate are arranged at the end of the air pipe 5 on the top of the site structure 8. The sealing plate 8 is used to open and close the buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com