Comparison spectrum system and measurement method for realizing high depth-to-width ratio micro-groove depth measurement

A technology of depth measurement and high aspect ratio, which is applied in the field of comparative spectral measurement system of high aspect ratio micro-groove depth, can solve the problem of limited Fourier analysis frequency resolution, large error of depth value, and influence of spectral analysis method on depth measurement range and other issues to achieve the effect of improving the calculation efficiency and accuracy of the solution and facilitating matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

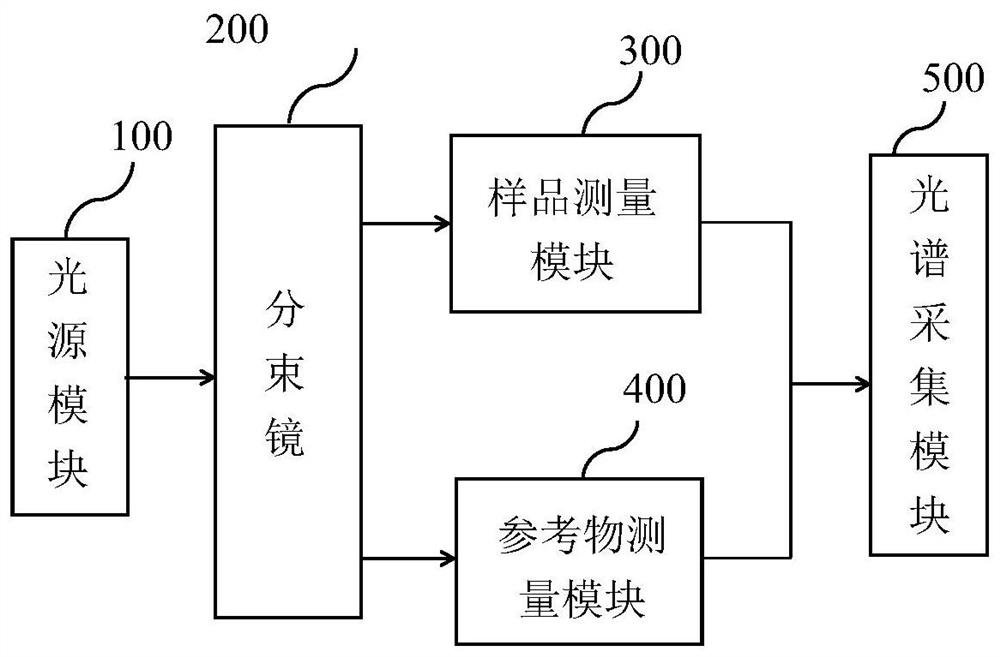

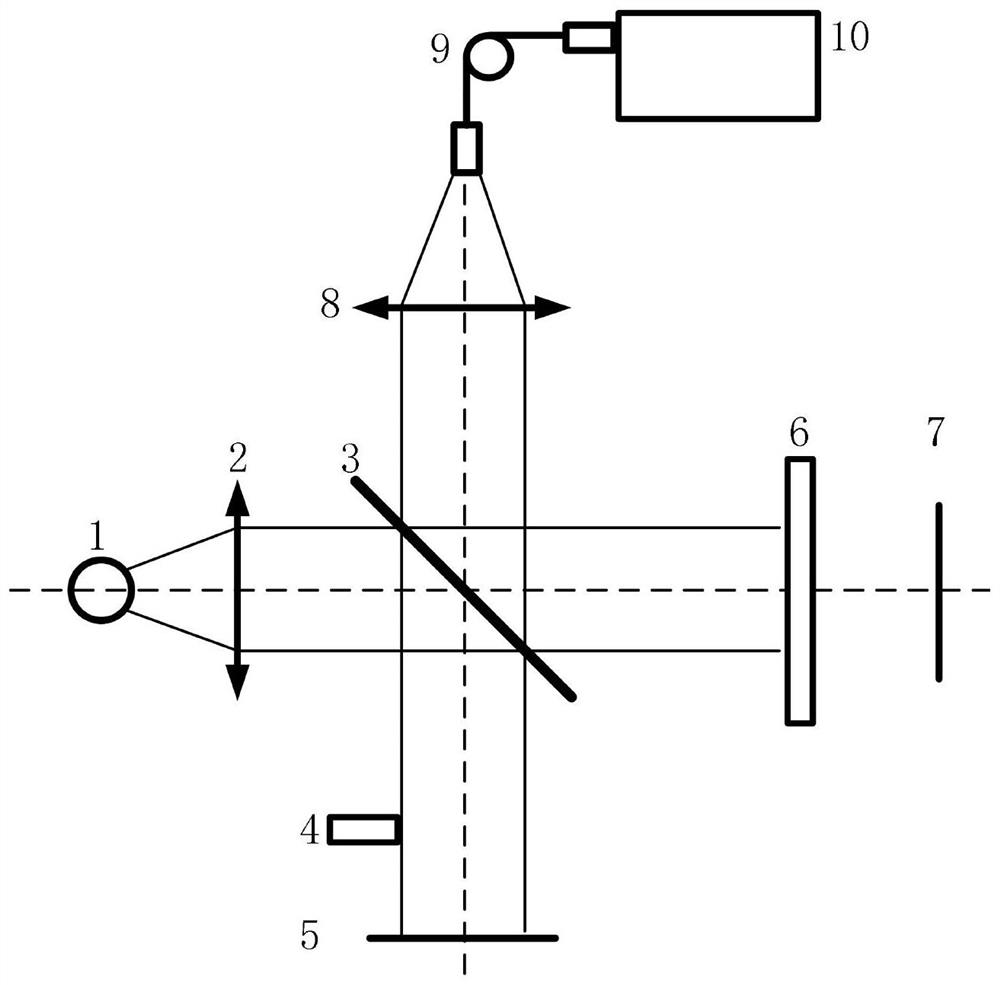

[0028] like figure 1 As shown in FIG. 1 , it is a structural schematic diagram of a comparison spectroscopy system for realizing the depth measurement of micro-grooves with high aspect ratio according to the present invention. The system includes a light source module 100 , a beam splitter 200 , a sample measurement module 300 , a reference object measurement module 400 and a spectrum collection module 500 . Wherein, the light source module 100 outputs an illumination beam with a set diameter; the illumination beam is divided into two beams of light by the beam splitter 200, and enters the sample measurement module 300 and the reference object measurement module 400 respectively; the sample measurement module 300 and the reference object measurement module 400 respectively The sample spectrum and the reference spectrum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com