High-pressure valve quick action test device

A technology of rapid action and test device, applied in the direction of mechanical valve testing, etc., can solve the problems of hard-to-be-tested valve support, low accuracy of test results, low valve stability, etc., to ensure stability, improve stability, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

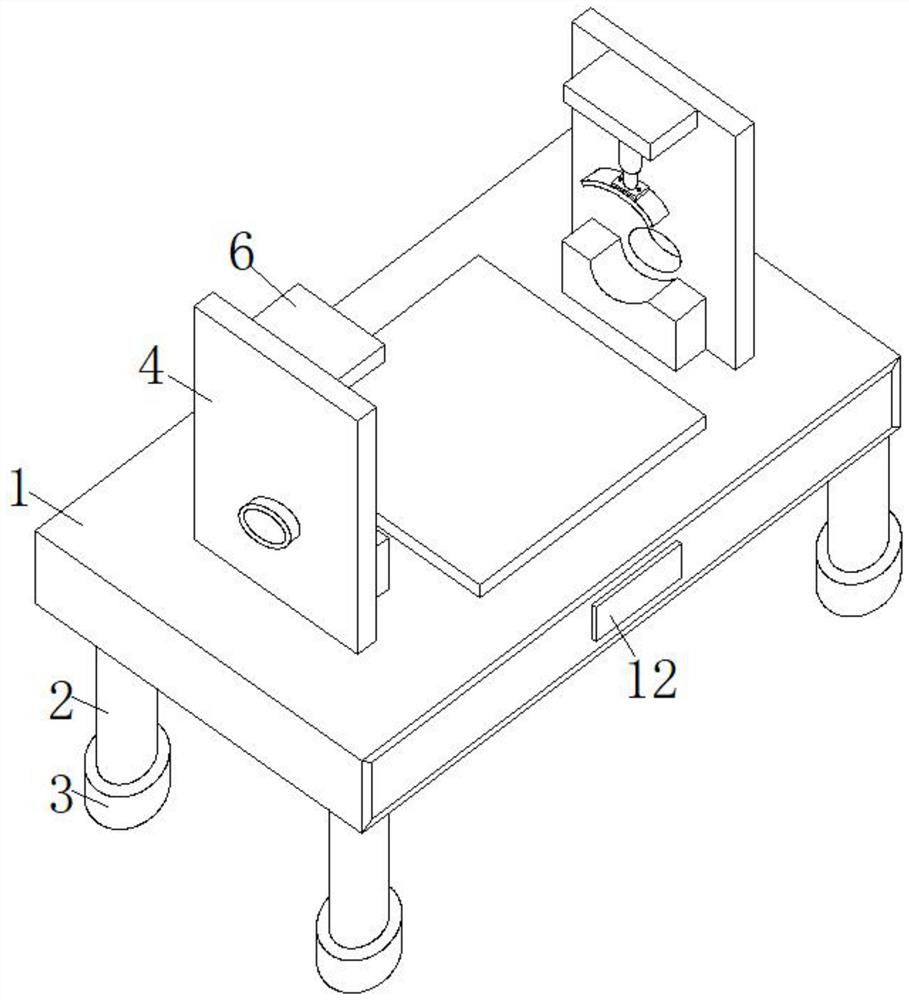

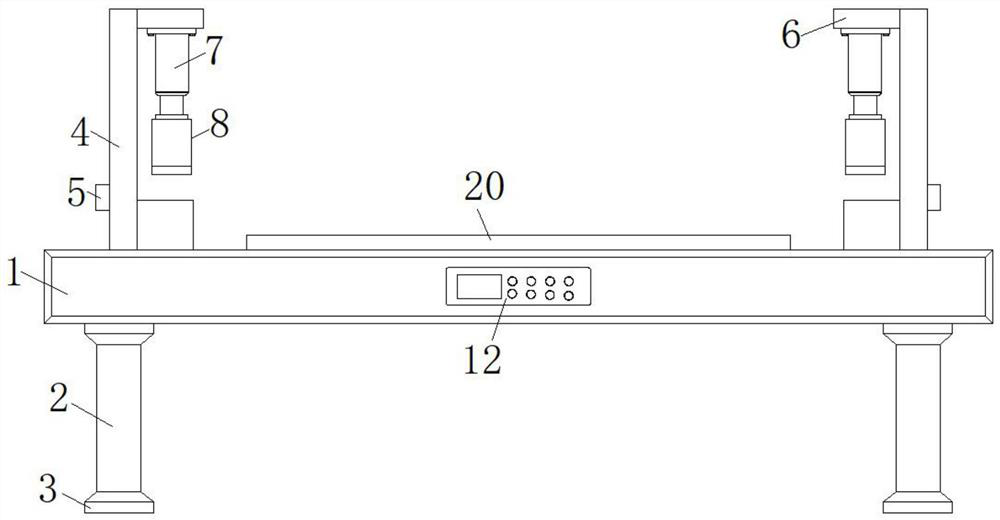

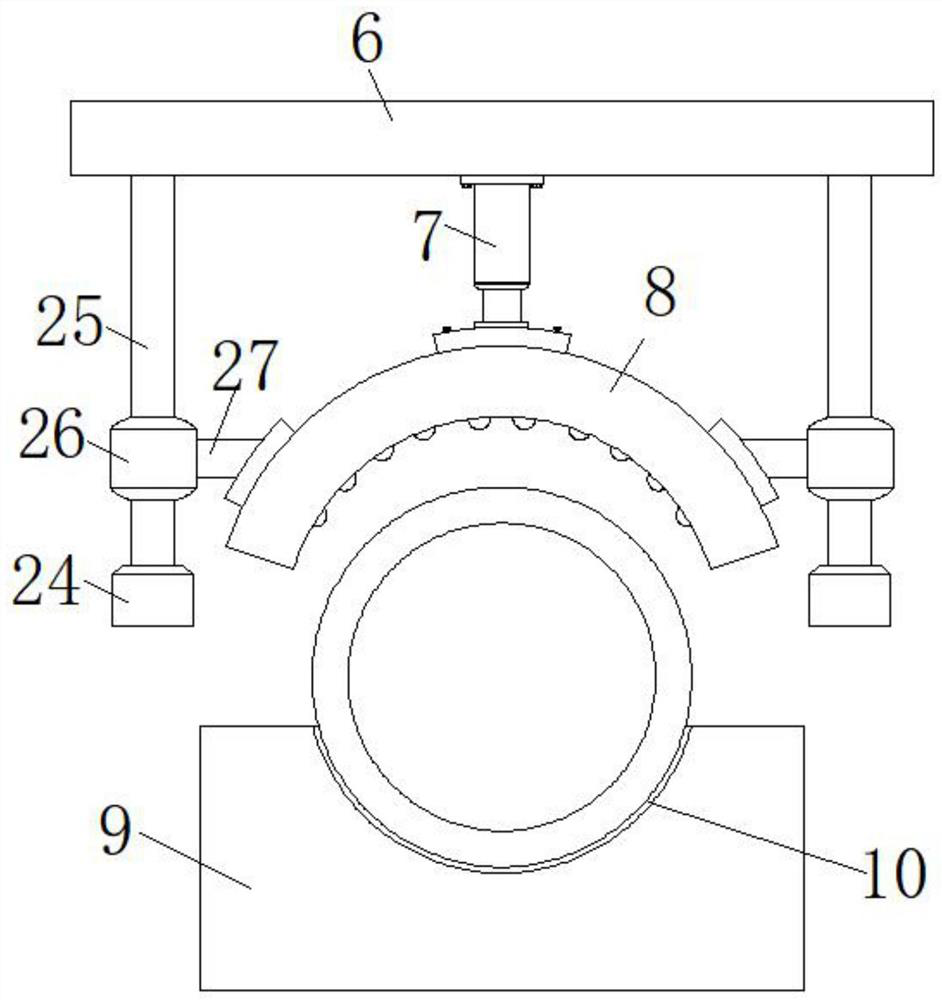

[0039] Such as Figure 1-6As shown, a high-pressure valve rapid action test device includes a test platform 1, and the bottom of the test platform 1 is fixedly equipped with evenly distributed support columns 2. The number of support columns 2 is four, and the four support columns 2 are evenly distributed. Distributed at the four corners of the bottom surface of the test platform 1, the bottom of the support column 2 is fixedly installed with a base 3, the base 3 is used for the connection between the support column 2 and the bottom surface, and the top surface of the test platform 1 is fixedly installed with two symmetrical The vertical boards 4, the sides of the two vertical boards 4 close to each other are provided with air ports 5, and the inner walls of the two air ports 5 are provided with O-shaped sealing rings, so as to increase the air inlets, air outlets and air outlets of external equipment. The tightness of the connection between the air ports 5, the two air ports ...

Embodiment 2

[0049] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that: the top surface of the valve placement plate 20 is fixedly installed with evenly distributed second springs 29, and the end of the second spring 29 away from the valve placement plate 20 is fixedly installed with a pad A block 30, the side of the cushion block 30 away from the second spring 29 is fixedly installed with an anti-slip pad 31.

[0050] Using a plurality of pads 30 instead of the valve placement plate 20 to contact the valve to be tested can make the contact area between the pads 30 and the surface of the valve to be tested larger, and at the same time, the bottom of each pad 30 is provided with a second spring 29, It can ensure that each pad 30 can be in contact with the surface of the valve to be tested, thereby improving the support effect of the valve to be tested, further improving the stability of the valve to be tested during the test, and the anti-skid pad 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com