Operating bed inspection device and inspection method

A technology of inspection device and inspection method, which is applied in the field of operating bed inspection, can solve the problems of long time consumption, high labor intensity, and difficult operation of manual fatigue test, achieve good reliability and economical practicability, and improve accuracy and safety Sex, the effect of reducing manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

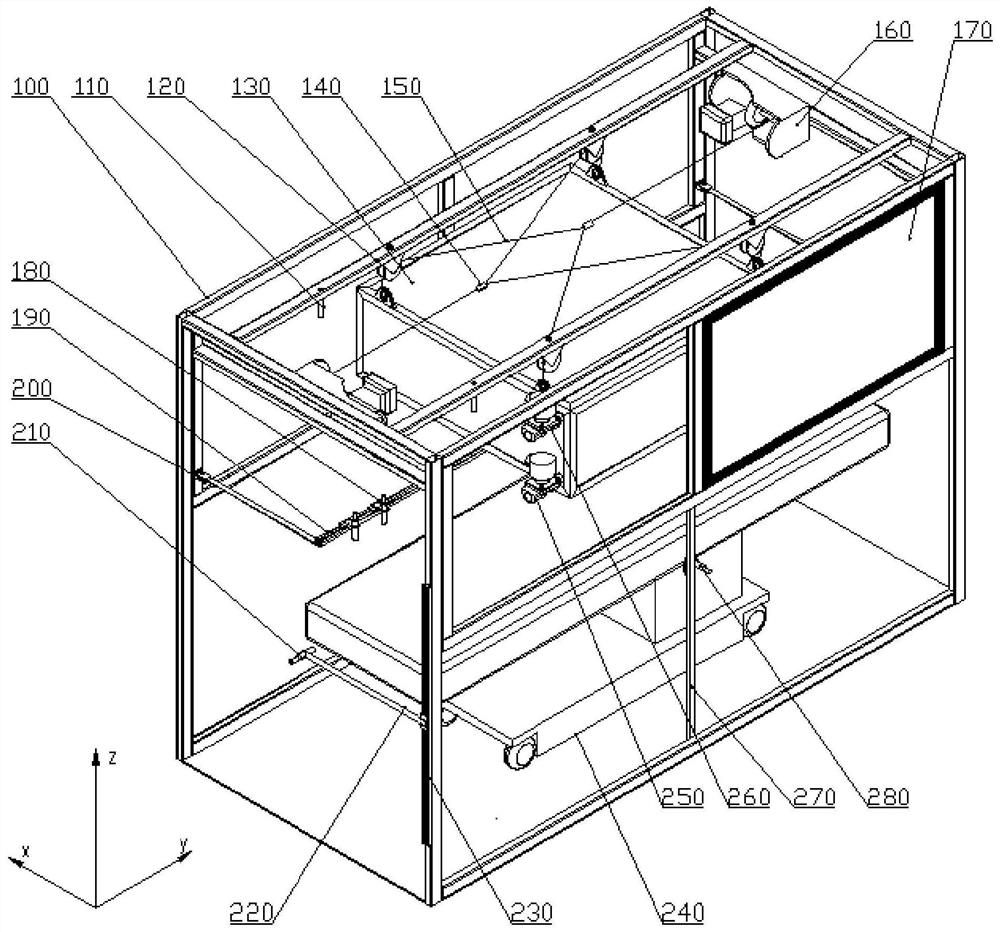

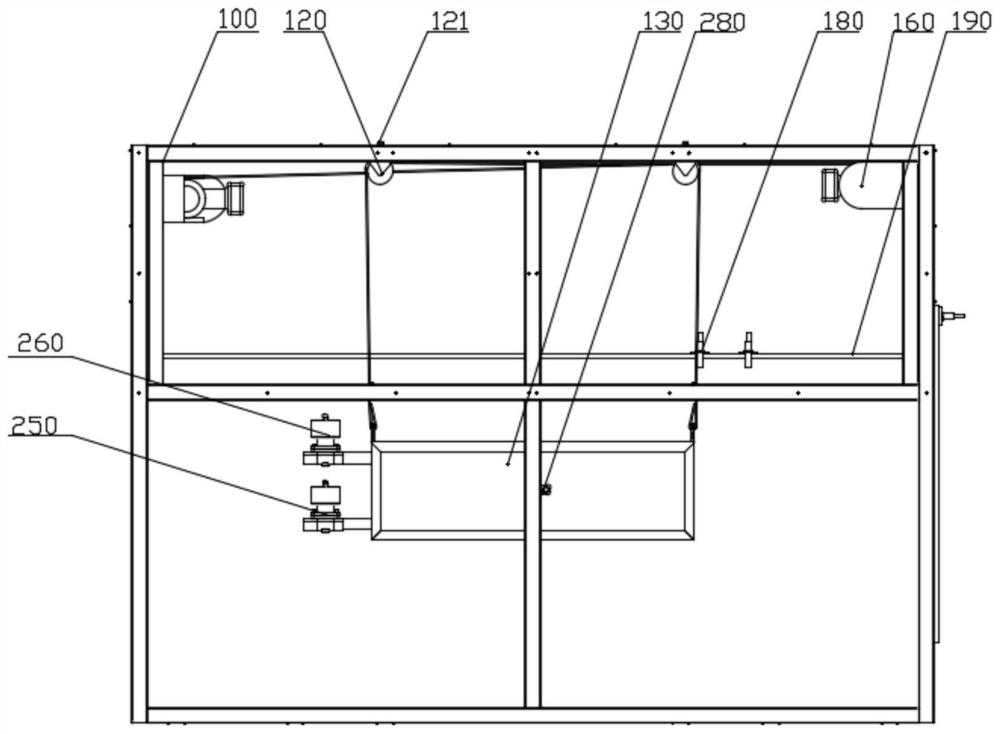

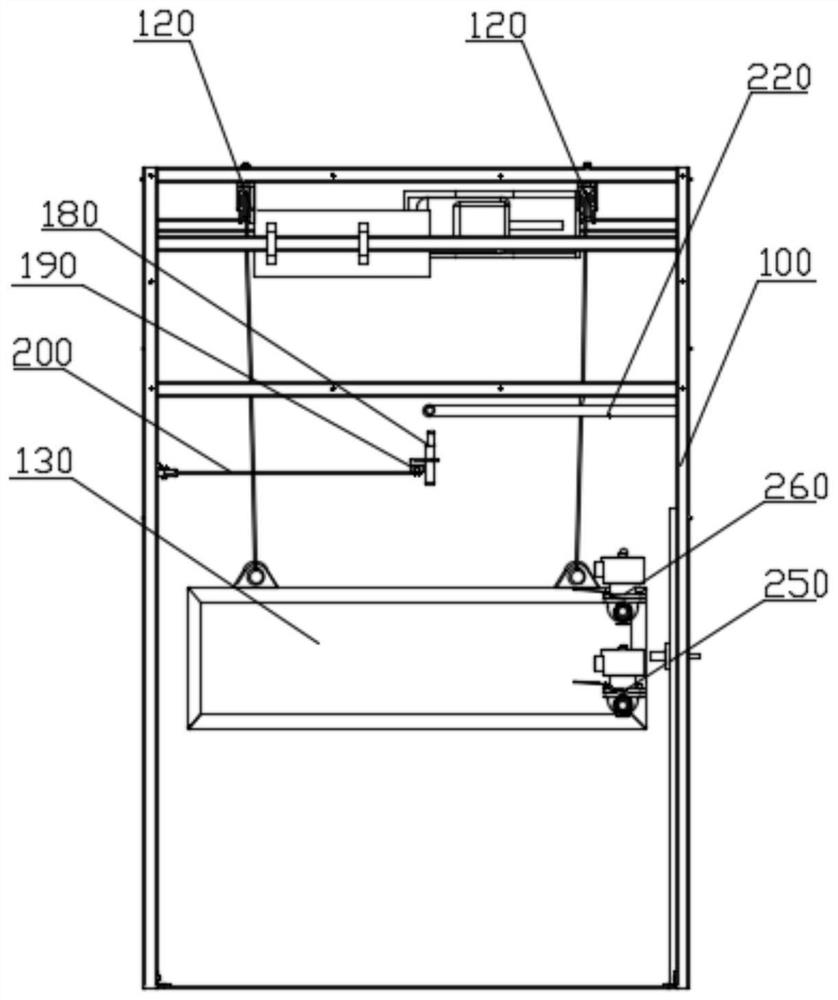

[0071] This embodiment is basically as Figure 1 to Figure 4 As shown: this embodiment provides an operating bed inspection device, which includes a frame 100, a water tank 130, a lifting mechanism, an X-direction displacement sensor, a Y-direction displacement sensor, and a control unit 170, which can be used to inspect the operating bed 240 load-bearing inspection, roll angle inspection and flip angle inspection, wherein the frame 100 can accommodate the operating bed, the water tank 130 is located inside the frame 100 and corresponds to the top of the center of the operating bed 240, and the water tank 130 is configured with a water inlet and a drain; the lifting mechanism and The water tank 130 is connected and arranged on the top of the frame 100 for driving the water tank 130 to move up and down in the vertical direction; the lifting mechanism is equipped with a tension sensor 140 for checking the weight of the water tank 130; and the lifting mechanism and the tension sen...

Embodiment 2

[0097] Embodiment 2 is basically the same as Embodiment 1, and the difference is that this embodiment combines the load-bearing test device and the displacement test structure in the same frame 100, providing a device that can automatically perform displacement tests, fatigue tests, and load-bearing tests. Diversified operating bed inspection device; in order to facilitate load-bearing inspection, such as Figure 10 to Figure 14 As shown, the Y-direction displacement sensor provided in this embodiment is equipped with a rotating link 200 mechanism, the second displacement sensor 180 is installed on the inner side of the frame 100 through the rotating link 200 mechanism, and the rotating link 200 mechanism and the inner side wall of the frame 100 rotate Specifically, when performing a load-bearing test, use the rotating link 200 mechanism to store the second displacement sensor 180 close to the inner wall of the frame 100 to avoid affecting the load-bearing test; The second dis...

Embodiment 3

[0103] The third embodiment is basically the same as the second embodiment, the difference is that this embodiment provides an operating bed inspection device, in order to improve the comprehensiveness of the operating bed performance detection, such as figure 1 As shown, this implementation also includes a third displacement sensor 210 and a fourth displacement sensor 280, the third displacement sensor 210 is installed inside the frame 100 and corresponds to the end face of the operating bed, and is used to check the longitudinal translation of the operating bed; as a preference, On the end face of the frame 100 is provided with along the vertical direction (ie figure 1 The second slide rail 230 arranged in the middle Z direction), the second slide rail 230 has a slider, and the matching connection mode between the slider and the second slide rail 230 is the same as that of the slider and the first slide rail 190 in the second embodiment above In the same way, the sliding and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com