Small photoionization detector and detection method thereof

A technology of photoionization and detectors, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of miniaturization and rapid on-site application, and achieve the effect of improving rapid detection capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

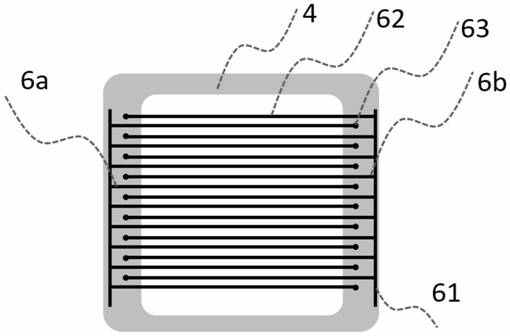

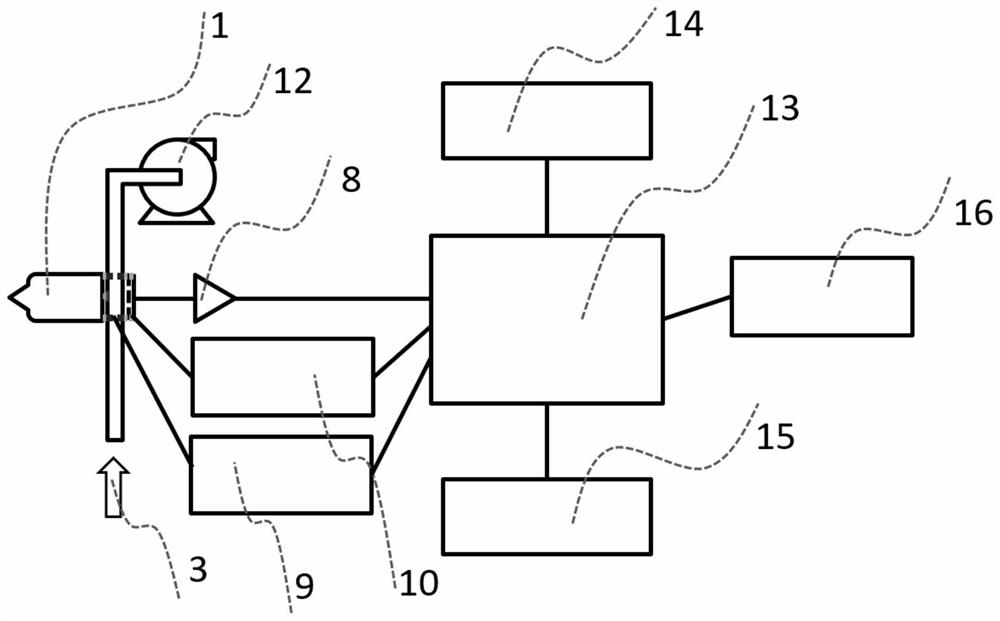

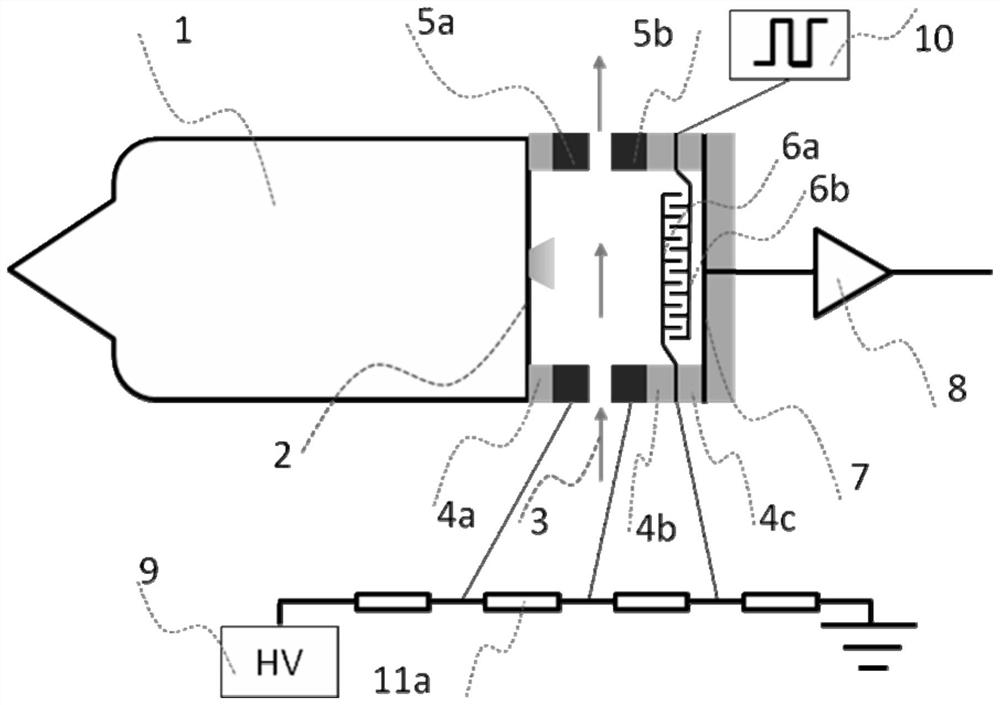

[0030] Such as Figure 1-Figure 2 A small photoionization detector shown includes a vacuum ultraviolet lamp 1 and a detection chamber installed on the right side of the vacuum ultraviolet lamp 1 . The detection chamber is installed on the glass window 2 of the vacuum ultraviolet lamp 1 . The detection chamber includes an insulating support cavity 4 and at least one traction electrode ring, an oscillating electrode one, an oscillating electrode two and a collecting electrode plate which are sequentially arranged on the insulating supporting cavity 4 from left to right; the collecting electrode plate is connected with A current amplifier, the current amplifier is connected with a controller; the left end of the insulating support cavity is provided with an ultraviolet light incident port; the surrounding wall of the insulating support cavity is provided with a gas inlet and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com