Fastening mechanism of high-voltage power sheath pipe and using method thereof

A technology of high-voltage electric power and fastening mechanism, applied in the direction of electrical components, etc., can solve the problems of damage to the sheath tube, uncontrollable locking force, shaking, etc., and achieve the effect of reliable heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

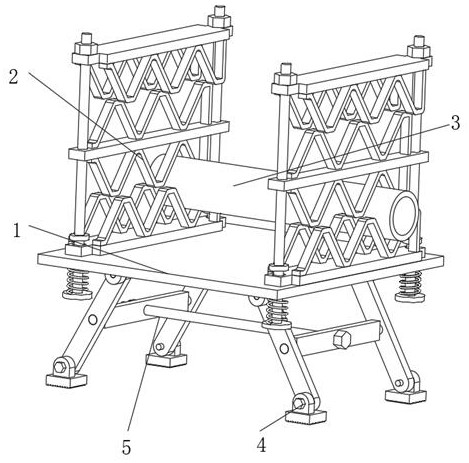

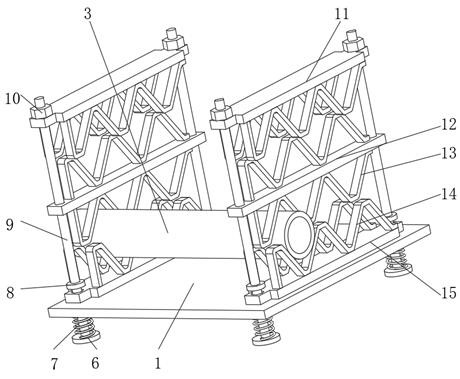

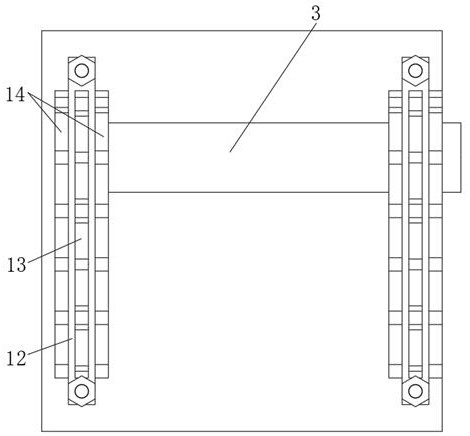

[0042] A fastening mechanism for high-voltage power sheath pipes, such as figure 1 , 2 As shown, it includes a table top 1, a flexible fastening assembly 2 arranged on the top of the table 1, and a sheath pipe body 3 fastened by the flexible fastening assembly 2. The flexible fastening assembly 2 includes a first bracket 13 and a second bracket 14. The top outer wall of the table 1 close to the locking rod 9 is fixed with a bottom plate 15 by bolts, wherein two second brackets 14 are installed in a linear array on the top outer wall of the bottom plate 15, and the four corners of the table 1 The inner walls are all slidably connected with locking rods 9, the outer walls of the locking rods 9 are respectively provided with a middle plate 12 and a top plate 11, and the other two second brackets 14 are installed in a linear array on the bottom outer wall of the top plate 11 , the two first brackets 13 are respectively fixedly installed on the top and bottom outer walls of the mi...

Embodiment 2

[0047] A fastening mechanism for high-voltage power sheath pipes, such as figure 1 , 4 As shown, in order to solve the problem of height adjustment; this embodiment makes the following improvements on the basis of embodiment 1: it also includes a second adjustment assembly 5, which includes four mutually symmetrical legs 18 and used in conjunction with The second adjusting screw 23 and the second adjusting nut 24, the bottom outer wall of the table top 1 is welded with the first hinge block 16, and the legs 18 are connected to the outer wall of the first hinge block 16 through the first hinge rod 17 in rotation , the inner walls of the two adjacent legs 18 are rotatably connected with adjustment plates 26 through the second hinge rod 25, the inner walls of the two adjustment plates 26 are provided with through holes, and the second adjustment screw 23 is wrapped On the inner wall of the through hole, the second adjusting nut 24 is threadedly connected to the outer wall of the...

Embodiment 3

[0050] A fastening mechanism for high-voltage power sheath pipes, such as figure 1 , 4 As shown, in order to solve the problem of height adjustment; this embodiment makes the following improvements on the basis of embodiment 2: it also includes a first adjustment assembly 4, which includes a first adjustment screw 20 and an anti-skid pad 21, The top outer wall of the anti-skid pad 21 is welded with a second hinge block 19, and the second hinge block 19 and the inner wall of the leg 18 are provided with adjustment holes, and the first adjustment screw 20 is arranged in the two adjustment holes. The inner wall on the other side of the first adjusting screw 20 is threadedly connected with a first adjusting nut 22; when the height is adjusted, the leg 18 rotates and the contact surface with the ground changes, which may cause Shaking, etc., and by being provided with the first adjustment assembly 4, before adjusting the height, the first adjustment nut 22 is loosened, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com