Display panel, manufacturing method thereof and display device

A technology for display panels and substrate substrates, which is applied in semiconductor/solid-state device manufacturing, diodes, semiconductor devices, etc., and can solve problems such as poor display effects of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

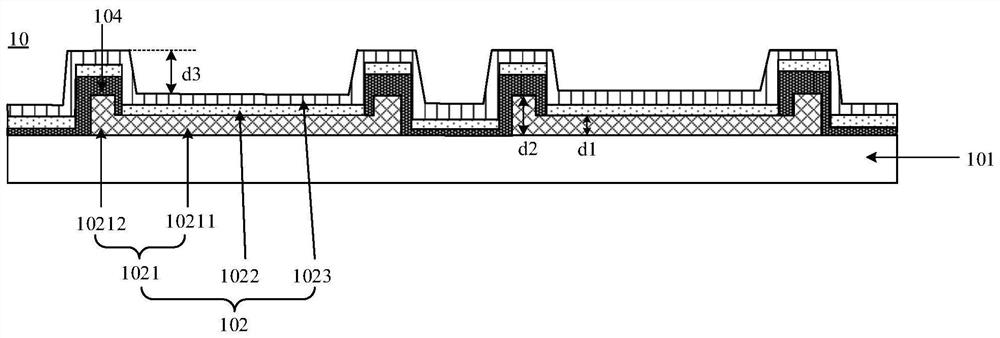

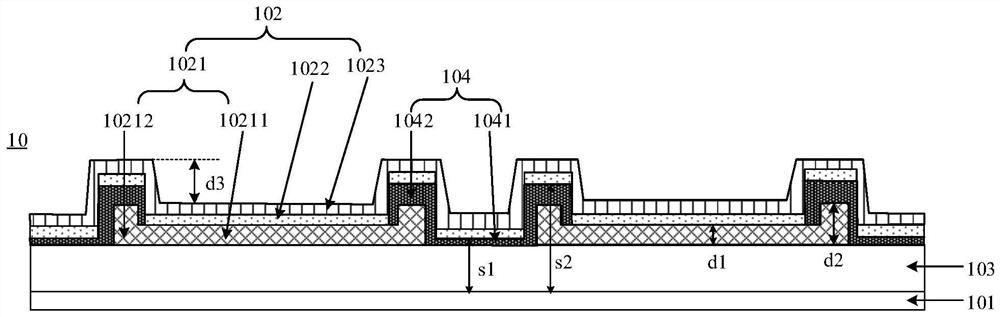

[0057] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0058] Silicon-based OLED display panels are widely used in virtual reality (virtual reality, VR) equipment, augmented reality (augmented reality) equipment, camera viewfinders or sights due to their advantages of ultra-high pixel density (pixels per inch, PPI). .

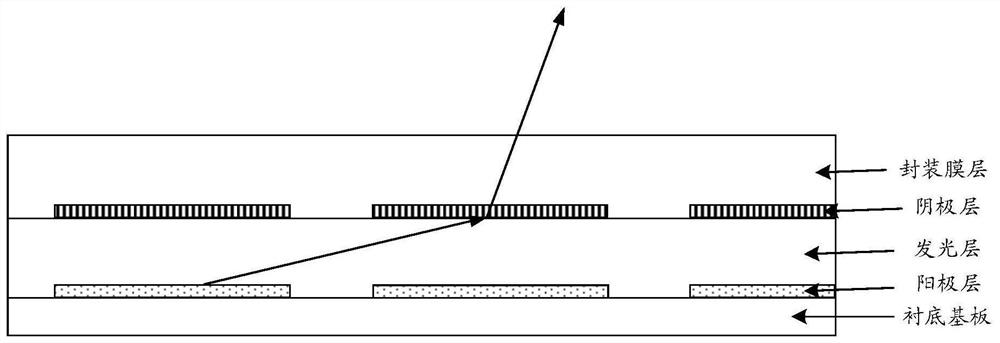

[0059] However, due to the small size of the sub-pixels in the silicon-based OLED display panel, the fabrication accuracy of the light-emitting layer of the sub-pixel 102 is low by using a mask. Therefore, under normal circumstances, the display panel can be prepared by adopting the scheme of white light OLED and color filter layer. That is, the light emitted by each sub-pixel in the display panel is white light, and the white light passes through the color filter la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com