Feeding mechanism and automatic cooker using feeding mechanism

A technology of feeding mechanism and vegetable box, applied in the field of cooking machines, can solve the problem of slow feeding rate, etc., and achieve the effect of improving feeding rate and ensuring cooking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

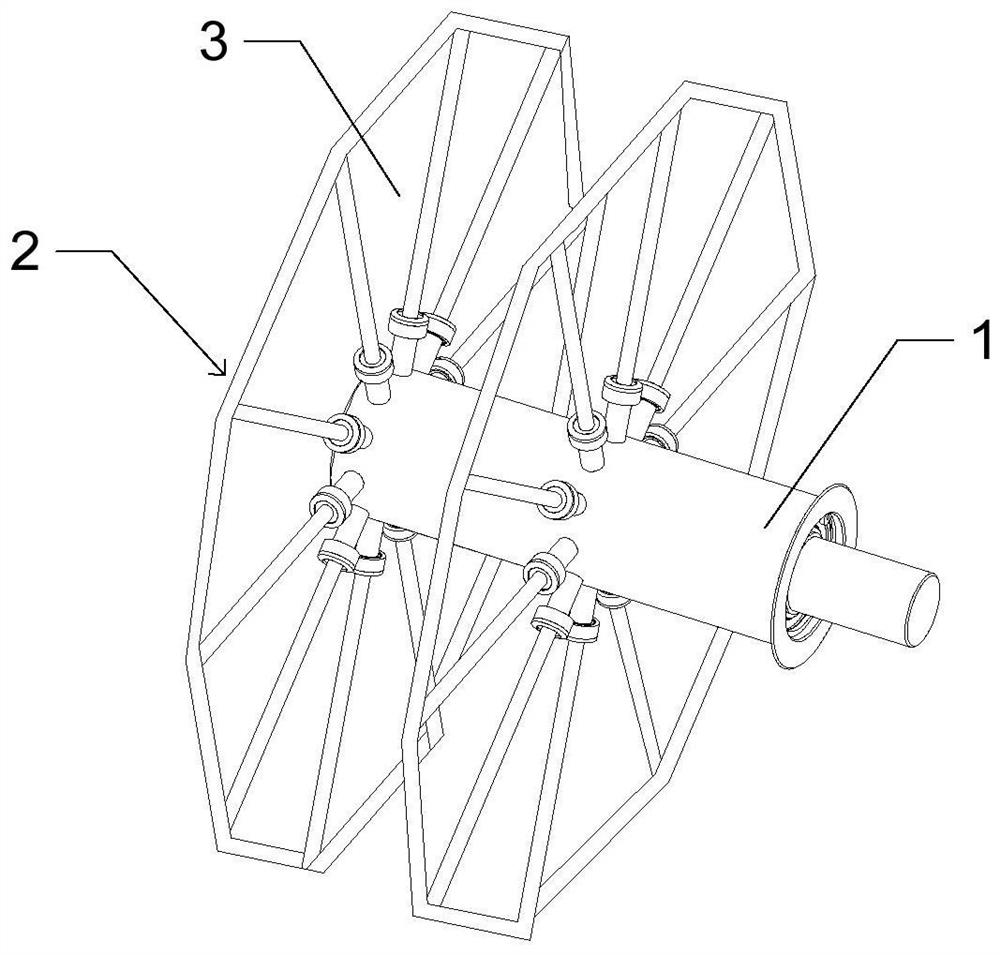

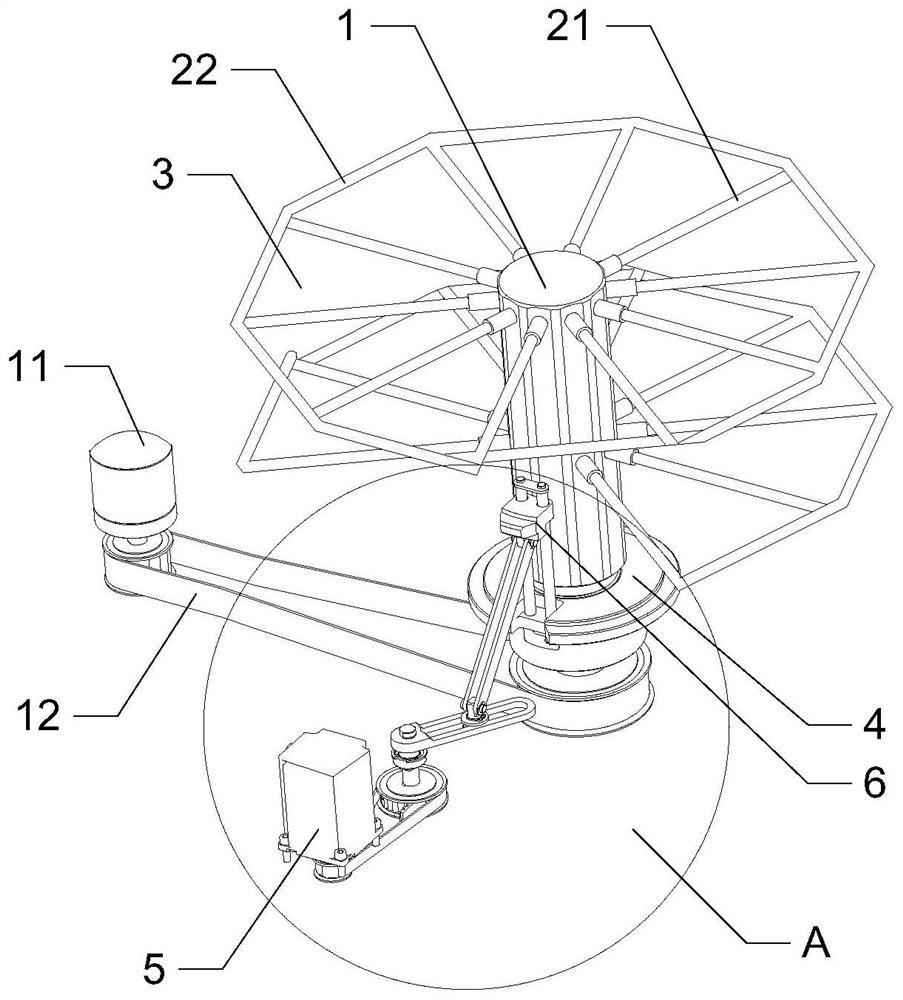

[0049] combined with Figures 1 to 8 As shown, a feeding mechanism is described, which can be applied to an automatic cooking machine to realize the feeding process, and the feeding mechanism is used for holding and supplying such as Figure 8 The shown vegetable box 7 filled with materials can quickly transport the vegetable box 7 to the feeding position of the cooking machine.

[0050] The feeding mechanism includes: a rotating shaft 1 and a support 2 arranged on the rotating shaft 1; a plurality of vegetable box accommodation spaces 3 are arranged on the support 2, and the plurality of vegetable box accommodation spaces 3 are circumferentially arranged around the rotating shaft.

[0051] In this example, if Figure 9 As shown, the vegetable box 7 conveyed has an outer box 73 and an inner box 72, wherein the inner box 72 is used for loading cooking materials, and the inner box 72 can extract the outer box 73, and when the inner box 72 is drawn out, the material can be poure...

Embodiment 2

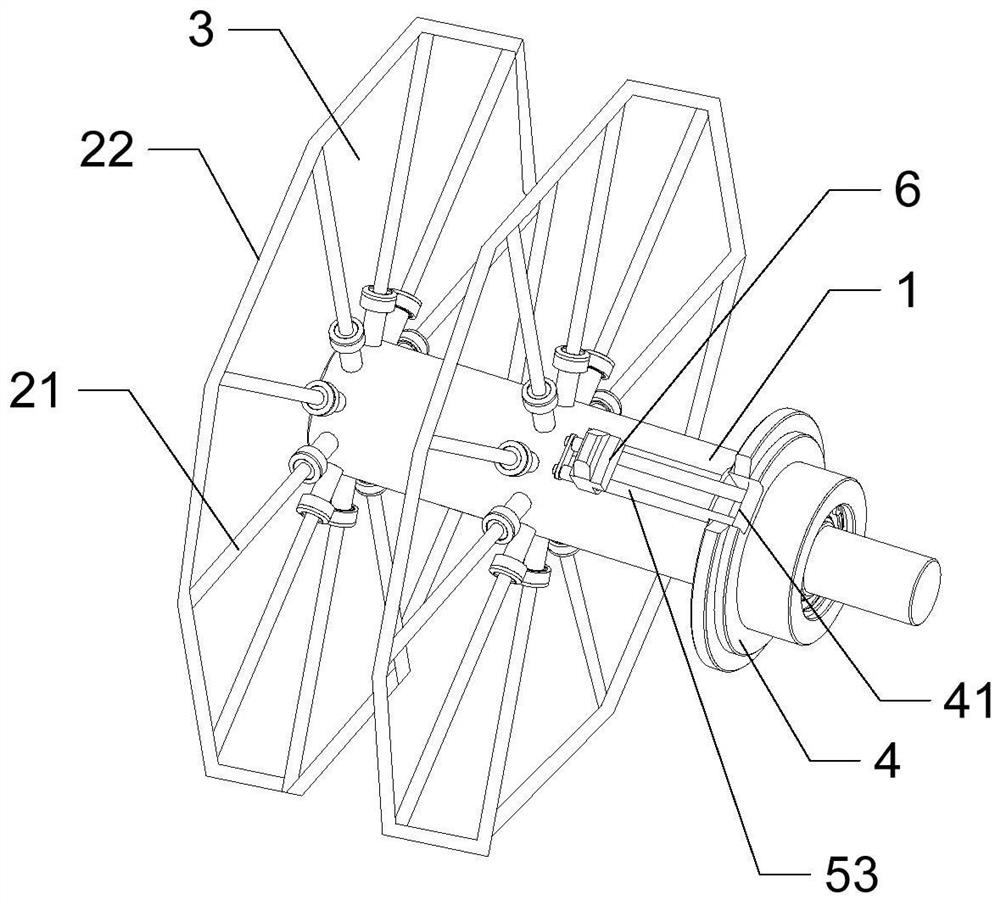

[0058] As an optional implementation of the present invention, on the basis of Example 1, as attached figure 2 Or as shown in 3, a fixed disk 4 is sleeved on the rotating shaft 1, the rotating shaft 1 can rotate relative to the fixed disk 4, and the fixed disk 4 is provided with a first limiting structure for limiting the axial movement of the vegetable box 7 along the rotating shaft 1, The vegetable box 7 is provided with a second limiting structure matched with the first limiting structure to allow the vegetable box 7 to rotate synchronously with the rotating shaft 1 . The axial movement of the vegetable box 7 can be limited by setting the first limiting structure and the second limiting structure, so as to prevent the vegetable box 7 from sliding out of the vegetable box accommodating space 3 .

[0059] Specifically, as an optional implementation of the first limiting structure, such as Figure 4 As shown, the first limiting structure can be an annular flange 42 arranged ...

Embodiment 3

[0071] As an optional implementation of the arrangement of the vegetable box accommodating space 3 , an openable or closable door body part is provided on the support 2 corresponding to each vegetable box accommodating space, so as to facilitate putting in or taking out the vegetable box 7 .

[0072] As an optional implementation of the bracket 2, as attached Figure 6 As shown, the bracket 2 includes at least two sets of support assemblies arranged at intervals along the axial direction of the rotating shaft 1. The support assemblies include multiple groups of support units 20 distributed radially, and a vegetable box is arranged between adjacent two support units 20. space3. Of course, the supporting components can also be three groups, four groups, six groups, etc., which are set according to actual conditions. However, in the present invention, the brackets 2 are divided into two groups.

[0073] Wherein, the supporting unit 20 is a rod body or a plate-shaped part, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com