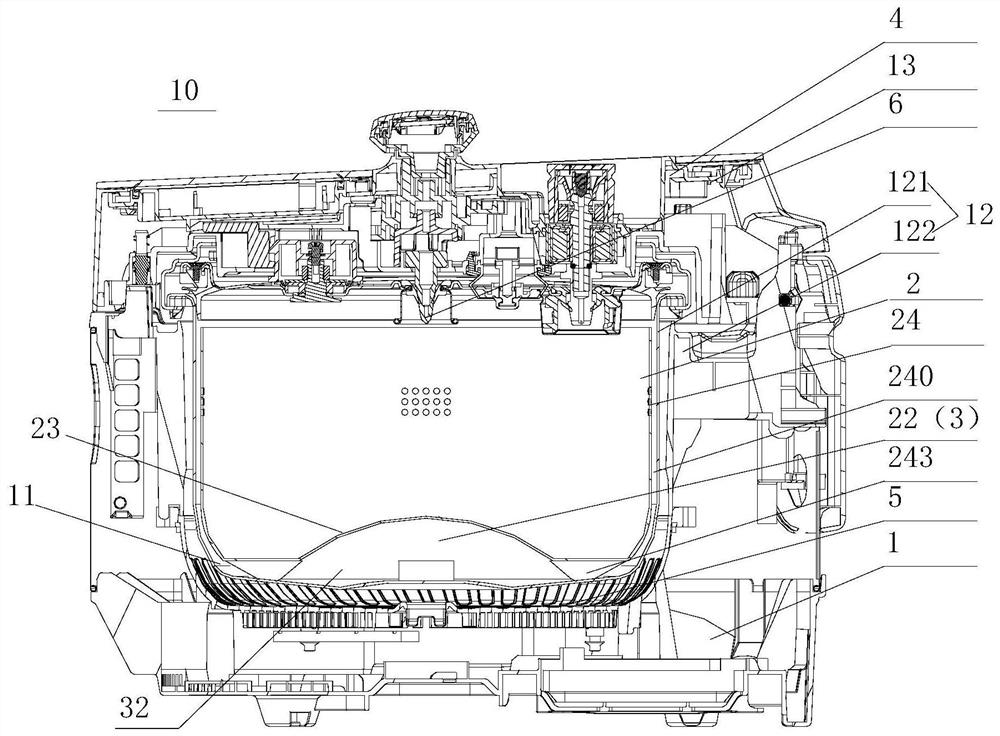

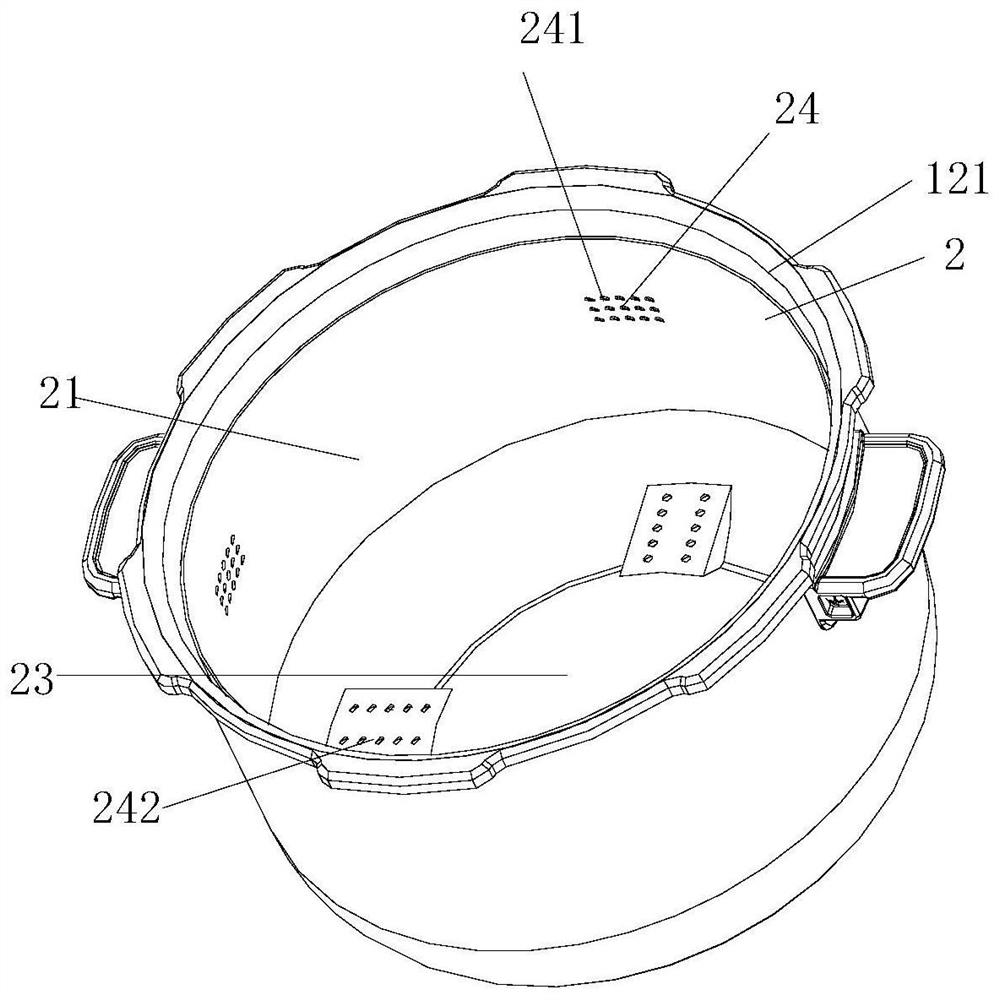

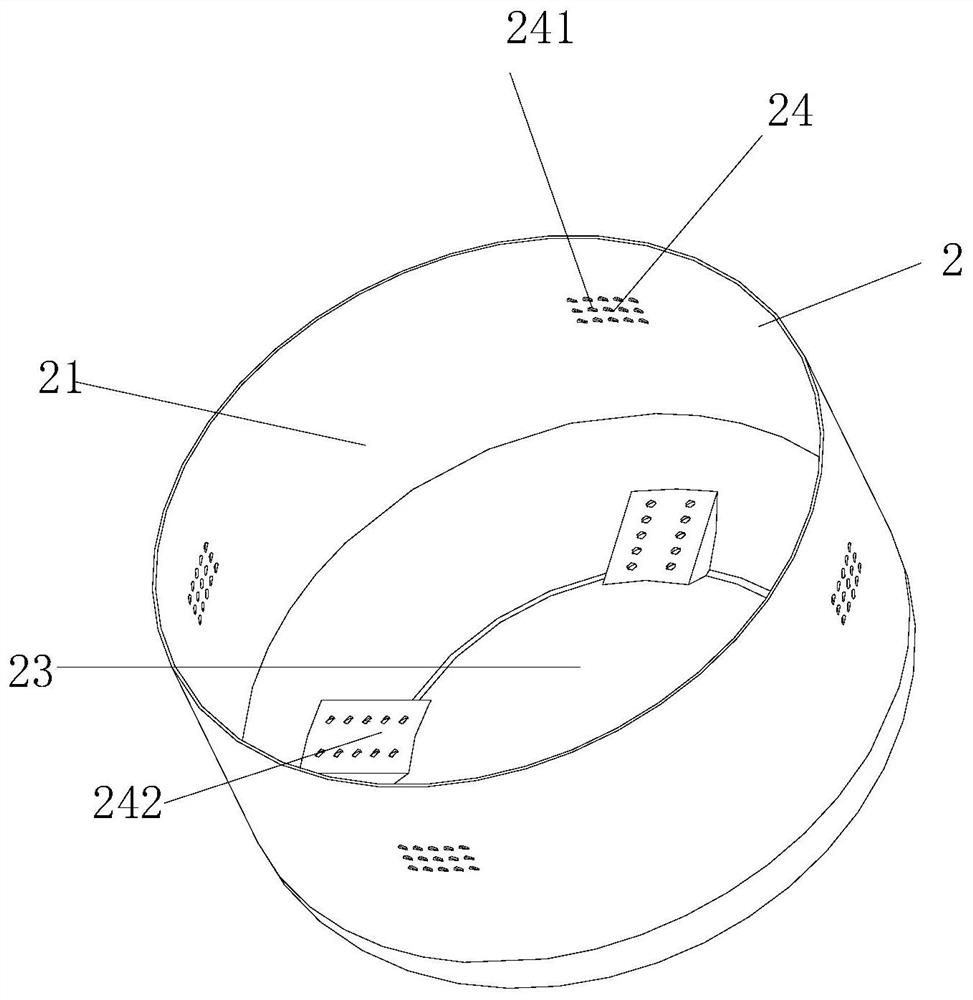

Pressure cooking utensil and cooking control method and device thereof

A technology for cooking utensils and control methods, which is applied to cooking utensils, household utensils, kitchen utensils, etc. It can solve problems such as exhaust time, long waiting time for opening lids, affecting user experience, and long cooking time, so as to shorten the cooking time. Effects of time, enhancing experience, and enhancing the effect of liquids and ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] Embodiment 1, the specific working process of pressureless cooking is as follows:

[0114] The user selects the quick soup cooking function, starts the quick soup cooking procedure, controls the heating device to heat the cooking cavity such as the inner pot, and meanwhile the detection part monitors the temperature of the cooking cavity. When the temperature in the cooking cavity reaches the first temperature threshold T0 (T0 range is 80-100 ° C), start timing t, open the exhaust device such as an exhaust valve to prevent positive pressure in the pot, the heating device continues to heat, and the cooking cavity The inner pot and the water in the holding part boil, and at the same time, the water in the medium replacement part boils to generate water vapor, and the pressure in the medium replacement part rises. The through hole enters the holding part, and another part of the water in the medium replacement part enters the holding part from the water channel, the gap an...

Embodiment 2

[0115] Embodiment two, the specific working process of pressure cooking is as follows:

[0116] Specific examples of micro-pressure cooking are as follows: the user selects the quick soup cooking function, starts the quick soup cooking procedure, controls the heating device to heat the cooking cavity such as the inner pot, and simultaneously monitors the pressure in the cooking cavity. When the pressure in the cooking cavity reaches the first pressure threshold P0 (during micro-pressure cooking, the range of P0 is 0-30KPa), start timing t, open the exhaust device such as the exhaust valve, the pressure in the cooking cavity drops, and the cooking cavity immediately The water in the inner pot and the storage part boils, and at the same time, the water in the medium replacement part boils to generate water vapor, and the pressure in the medium replacement part rises. Under the action of the pressure, part of the water in the medium replacement part enters through the bottom wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com