Tool clamp for machining thin-wall workpiece

A thin-walled workpiece and clamping technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of deformation of thin-walled workpieces and difficult clamping of thin-walled workpieces, and achieve uniform distribution of clamping force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

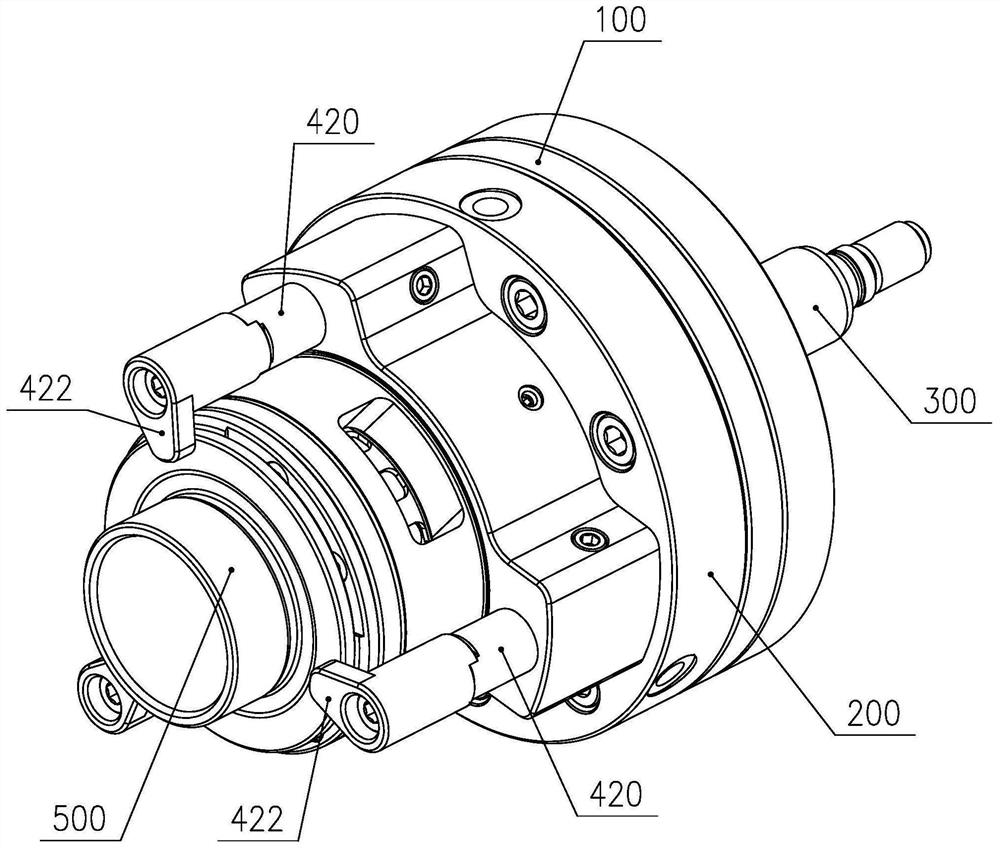

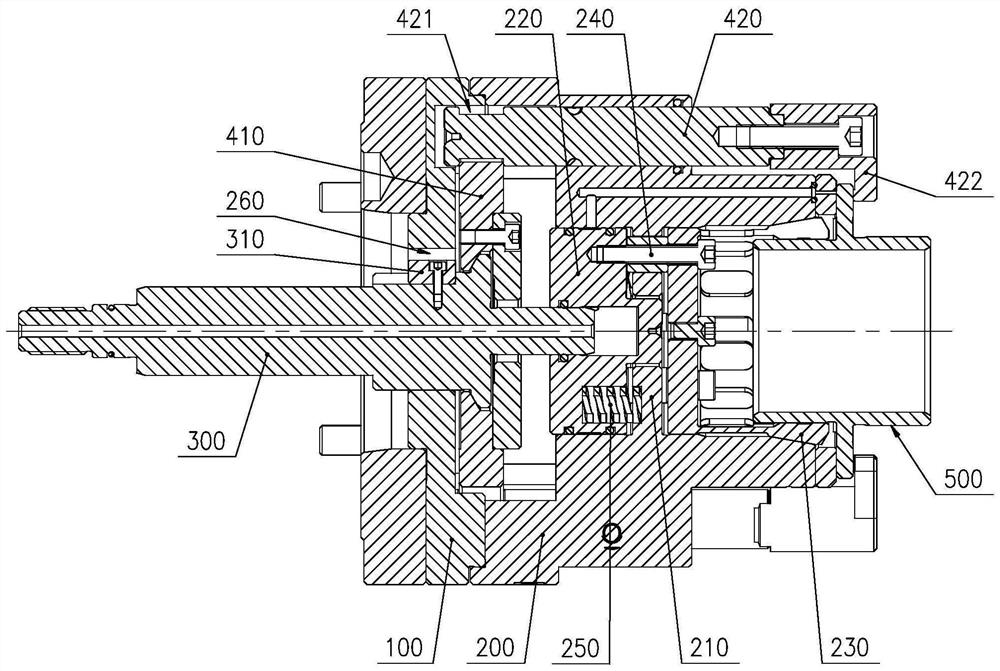

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

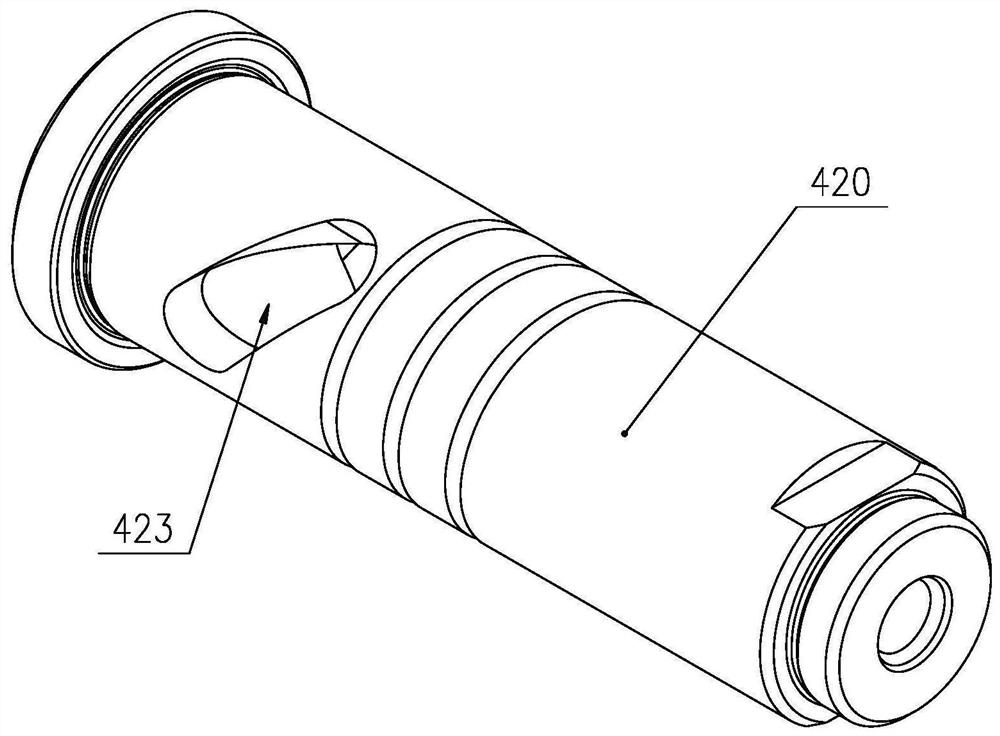

[0022] like figure 2 As shown, the tooling fixture for thin-walled workpiece processing includes a fixture plate 100, a clamping body 200 and a machine tool tie rod 300; A blocking ring 210 is fixed in the clip cavity, and the blocking ring 210 divides the clip cavity into a clip hole and a slider cavity, and a sliding block 220 is slidably arranged in the slider cavity , the clip hole is conical and is provided with a matching elastic jacket 230. The elastic jacket 230 is connected with the sliding block 220 by the connecting piece 240 passing through the stop ring 210. A spring 250 is arranged between the sliding block 220 and the retaining ring 210 ; one end of the machine tool tie rod 300 extends into the working cavity through the fixture plate 100 and corresponds to the sliding block 220 ; the machine tool tie rod 300 can drive the sliding block 220 In the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com