A three-dimensional mixing device for engineering construction

A mixing device and engineering construction technology, which is applied in the direction of cement mixing device, liquid ingredient supply device, clay preparation device, etc., can solve the problem of uneven mixing of materials, and achieve the effect of uniform material mixing, clear functions, and not easy to get stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

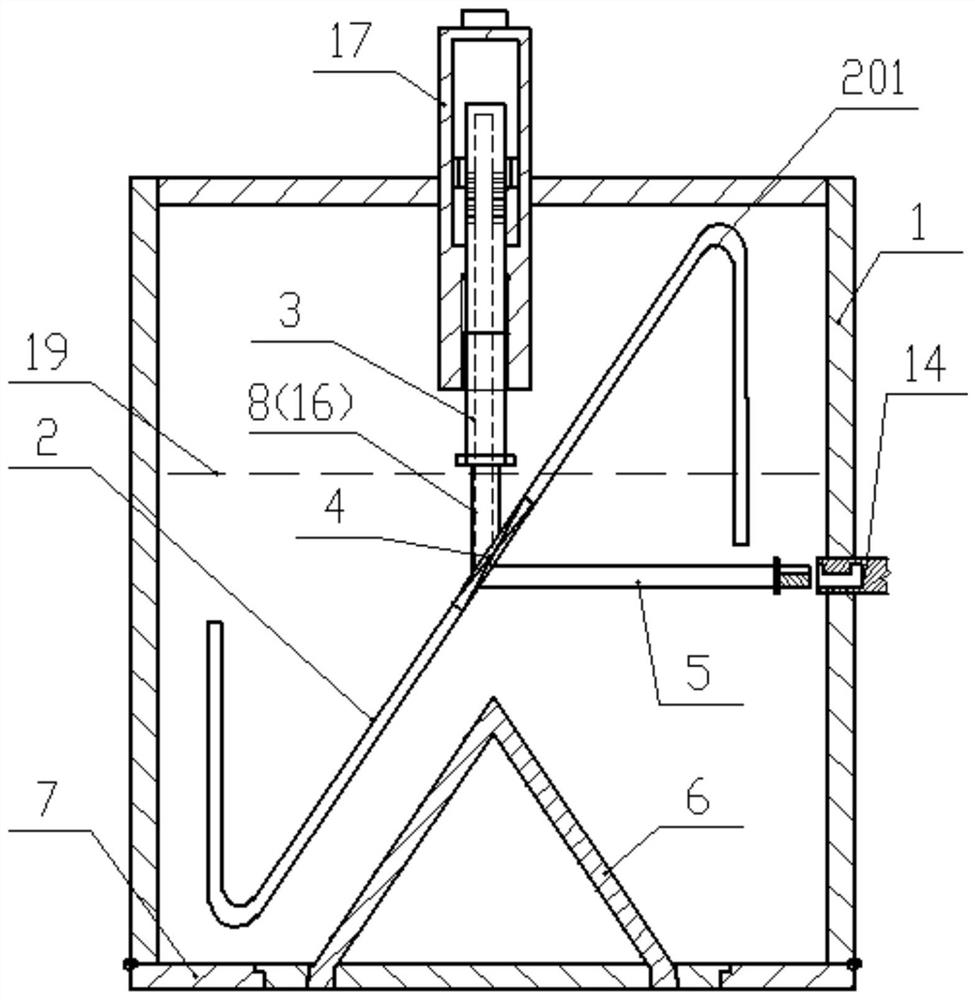

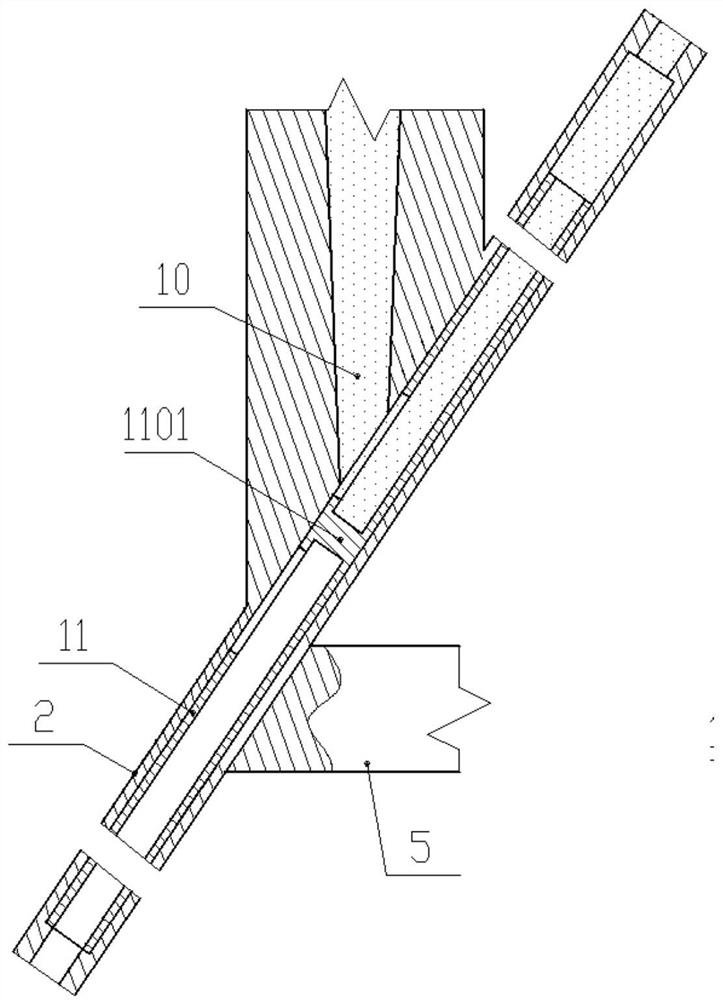

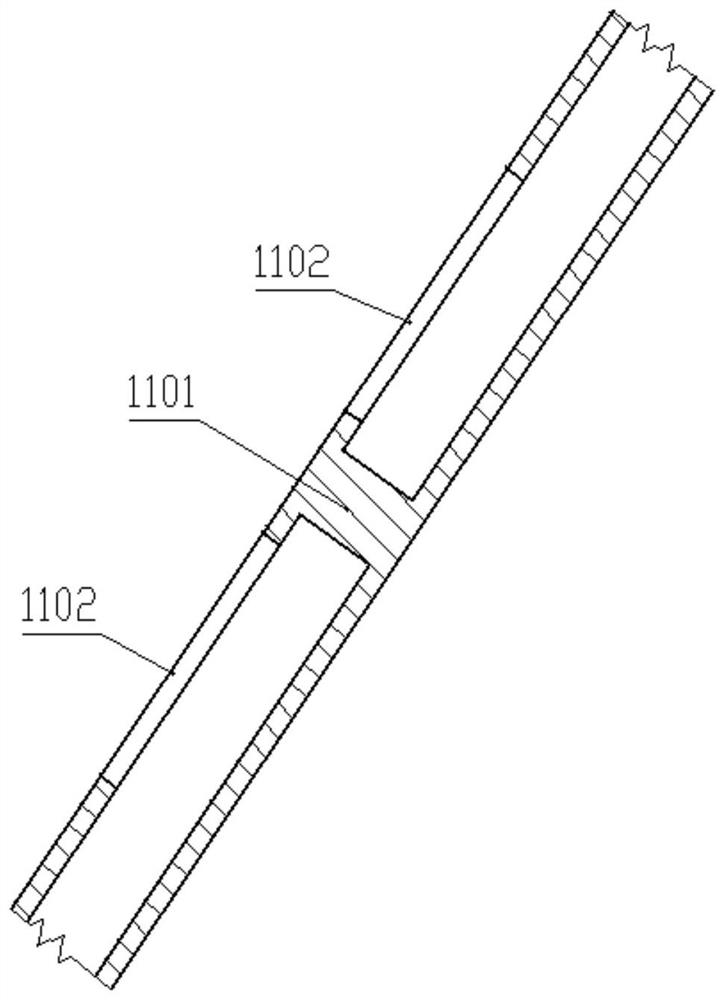

[0025] Such as figure 1As shown, this embodiment describes a three-dimensional mixing device for engineering construction, which includes a mixing tank 1 for containing concrete and a mixing device installed in the mixing tank 1. The bottom of the mixing tank 1 has an upward bulge The conical raised splitter. The stirring device includes a hollow vertical shaft 3, a hollow stirring rod 2, and a horizontal rotating shaft 5; the stirring rod 2 includes two integrally connected V-shaped stirring hooks 201 that are symmetrical to each other, so that the stirring rod 2 is Horizontally placed "Z" structure, the side wall of the stirring hook 201 is provided with a number of water spray holes, so that when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com