Classroom blackboard dust collection system

A technology for vacuuming systems and blackboards, applied in the field of vacuuming systems for classroom blackboards, can solve the problems of floating in the air and affecting the surrounding environment, and achieve the effect of reducing pollution and ensuring environmental sanitation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

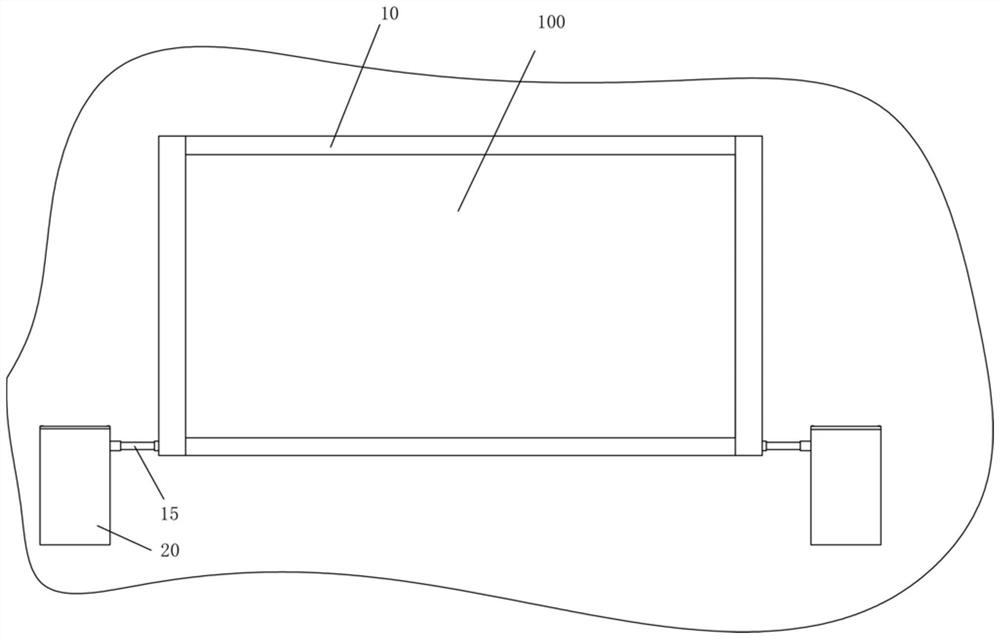

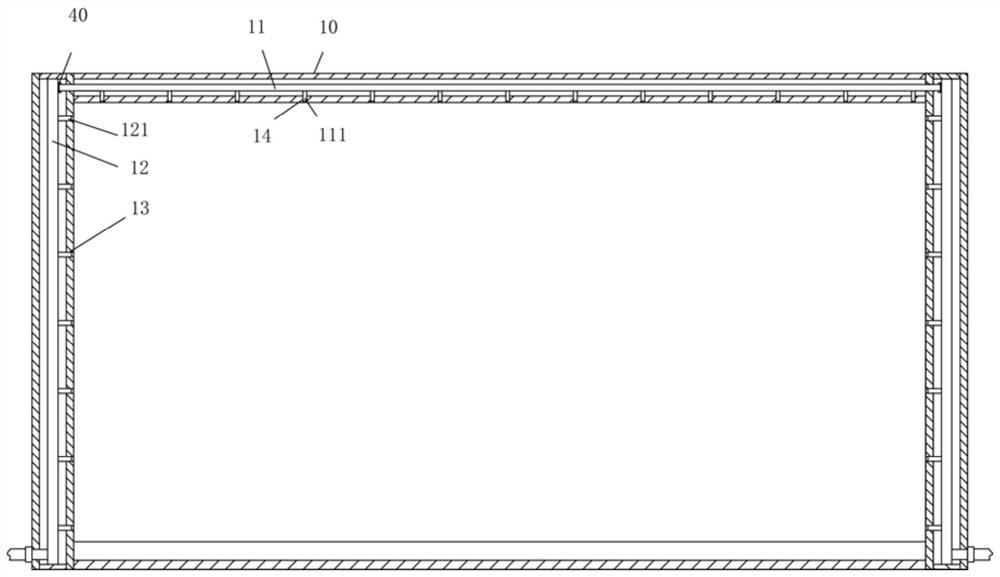

[0024] Examples, see as Figures 1 to 4 As shown, a classroom blackboard cleaning system includes a blackboard main body 100, and a pipe body 10 is fixed on the upper part of the blackboard main body 100 and the walls on the left and right sides;

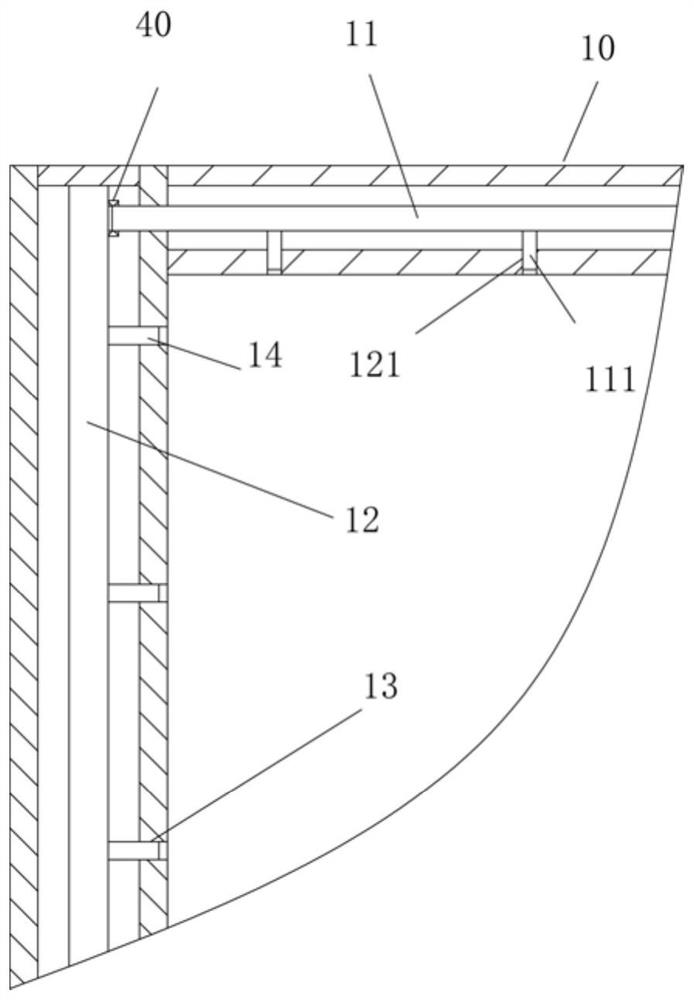

[0025] A suction air duct 11 is inserted into the upper duct body 10, and both ends of the suction air duct 11 extend into the duct bodies 10 on the left and right sides;

[0026] Vertical suction ducts 12 are inserted into the duct bodies 10 on the left and right sides, and both ends of the vertical suction duct 12 are fixed on the top and bottom plates of the duct bodies 10 on the left and right sides;

[0027] The two ends of the suction duct 11 are clamped in the fixing sleeves 40 fixed on the upper side walls of the two vertical suction ducts 12, and communicate with the two vertical suction ducts 12;

[0028] A plurality of upper suction pipes 111 are communicated with the bottom wall of the suction duct 11 , and a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com