Miniature double-flapping-wing air vehicle

A flapping aircraft and aircraft technology, applied in the field of micro aircraft, can solve problems such as lift lift, control mechanism and control rate simplification, and achieve the effects of reducing weight, reducing power consumption, and saving control software and hardware resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

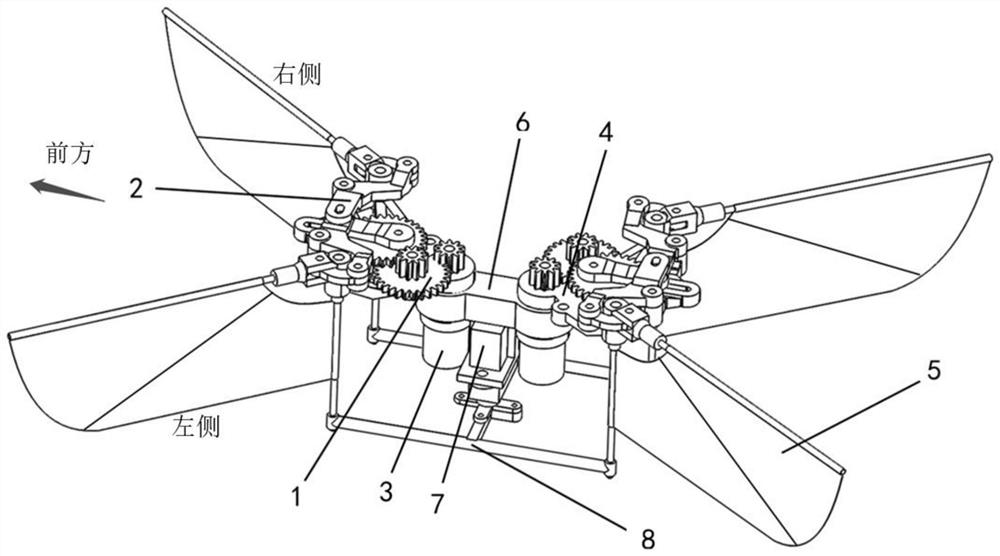

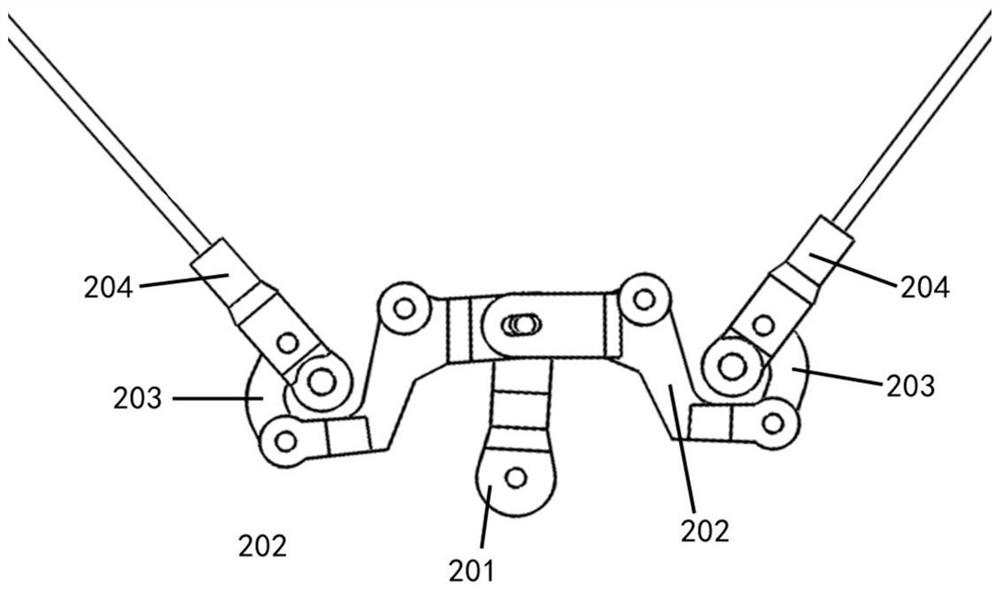

[0029] Such as figure 1 As shown, a miniature double flapping wing aircraft of the present invention takes the direction of the arrow in the figure as the front, and is controlled by two completely identical flapping wing systems, an intermediate connection structure 6, an attitude control steering gear 7, and a wing root position. The organization consists of 8. Each flapping wing system includes a reduction gear set 1, a flapping angle amplification mechanism 2, a hollow cup motor 3, a base 4, and flapping wings 5.

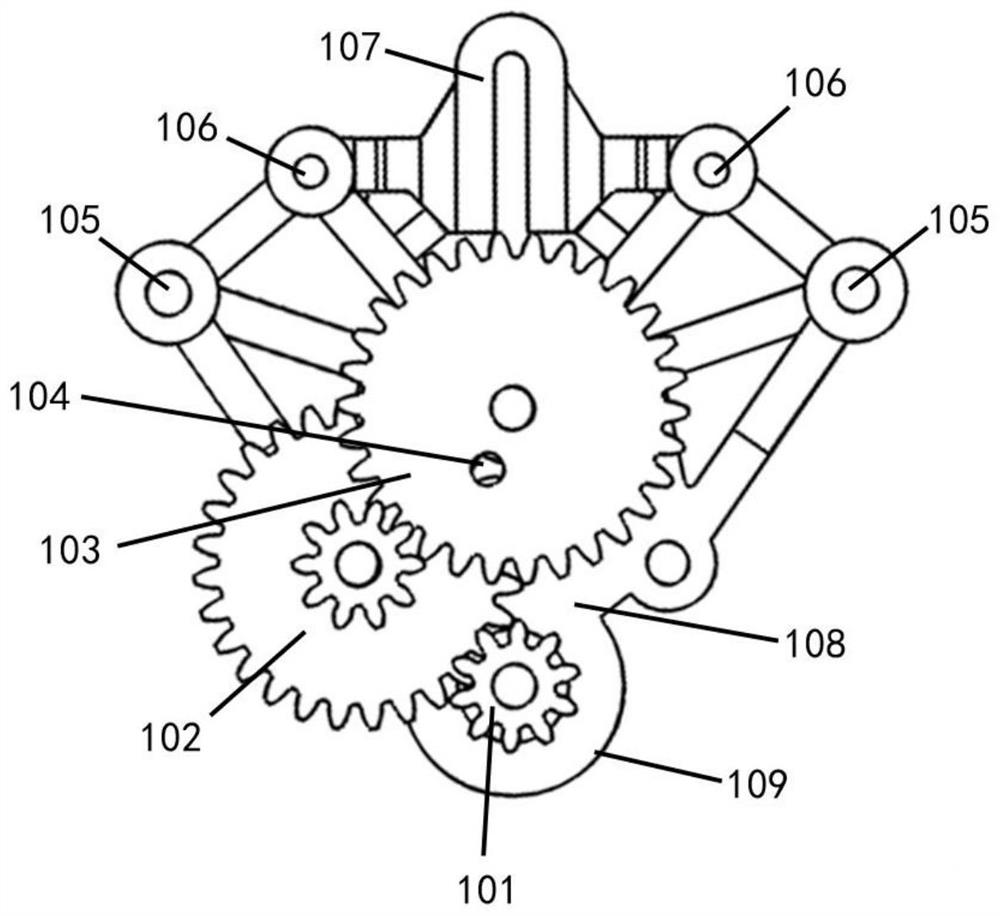

[0030] Such as figure 2 As shown, the reduction gear set 1 includes a main shaft gear 101 , a double-layer gear 102 and a bull gear 103 . The main shaft gear 101 is installed on the output shaft of the hollow cup motor, the large gear 103 and the double-layer gear 102 are installed in the middle mounting hole of the base 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com