Cured finished product hoisting and transferring device for aerated concrete production

A technology of air-entrained concrete and transfer device, which is applied in the directions of cleaning device, transportation and packaging, load hanging element, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

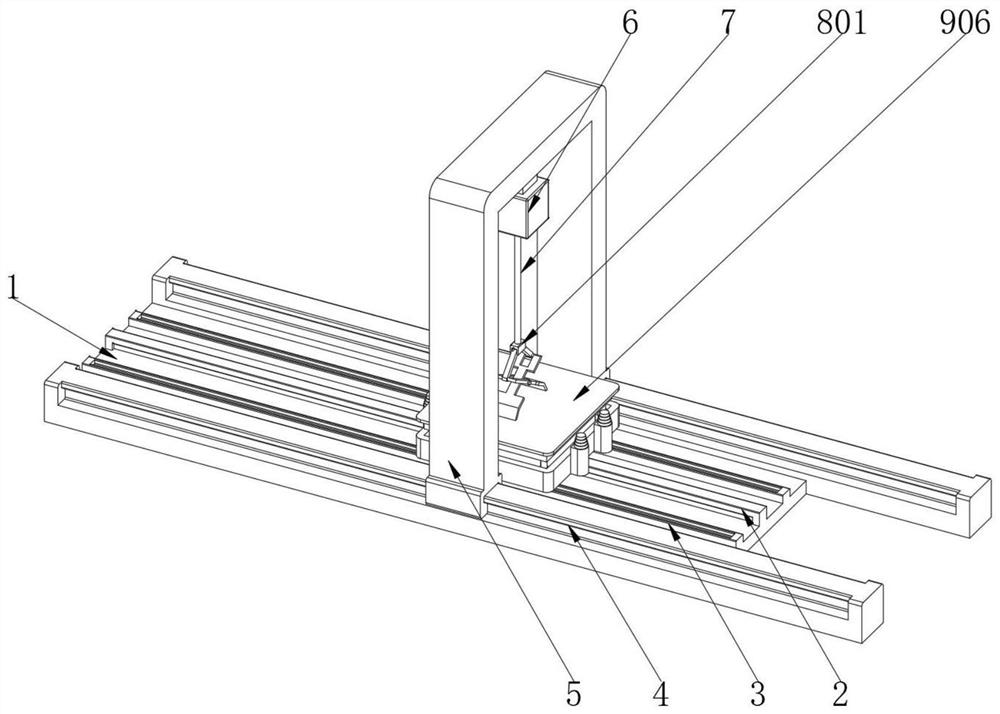

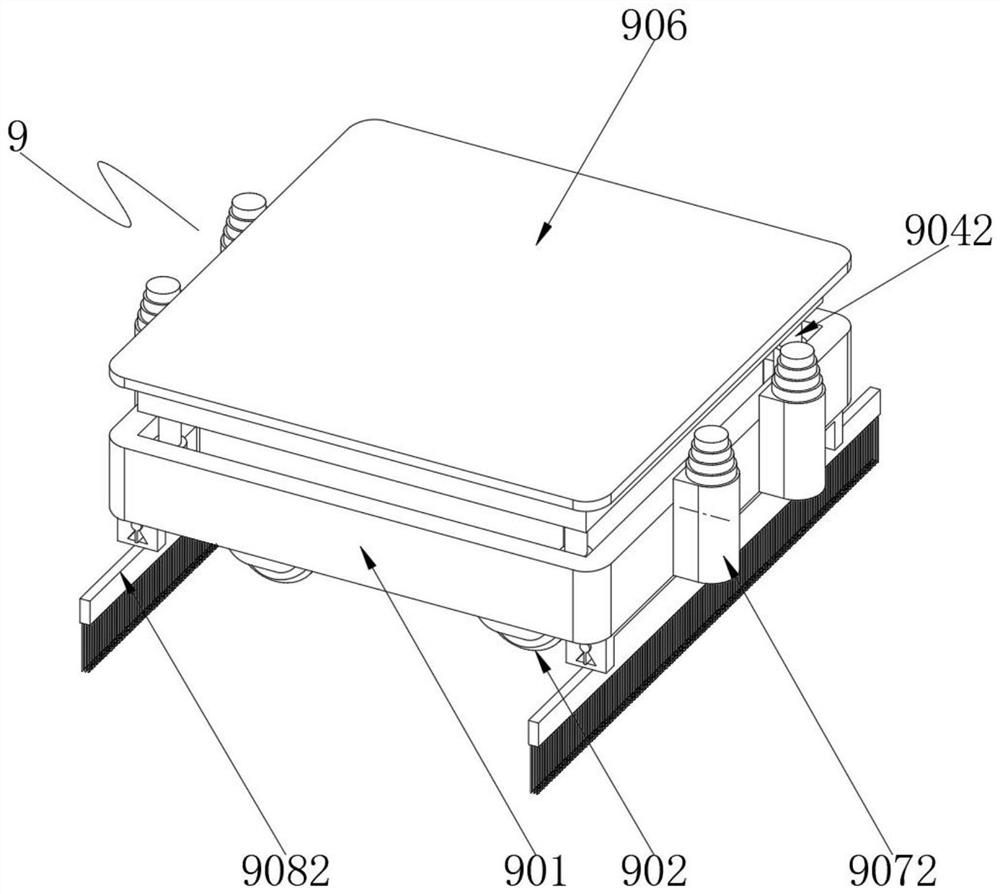

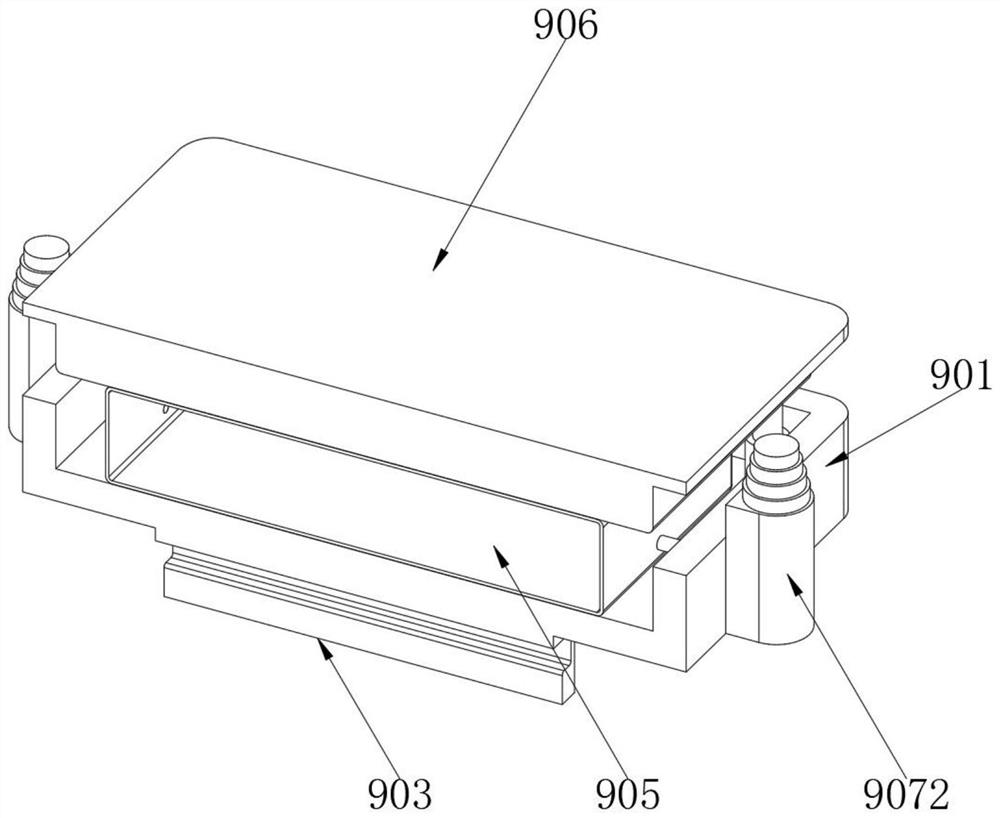

[0049] Example: such as Figure 1-11 As shown, a device for hoisting and transferring finished products of maintenance for the production of aerated concrete, including a transfer base 1, a gantry frame 5 and a transfer assembly 9, a first moving slide rail 2 is set in the middle of the upper surface of the transfer base 1, and the first moving slide The rail 2 is used to limit the position of the transfer assembly 9 during the transfer process. The first moving slide rail 2 is provided with a moving chute 3 on both sides. The moving chute 3 is used for the movement of the transfer assembly 9. The moving chute 3 There are second moving slide rails 4 on both sides, and a gantry 5 is installed above the second moving slide rails 4. The gantry 5 is used for hoisting the aerated concrete, and a slidable hoisting motor box 6 is installed under the gantry 5. The motor inside the hoisting motor box 6 is used for hoisting the aerated concrete, the output shaft of the motor is wound wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com