Frame structure of motor bicycle

A motor two-wheeled vehicle and frame technology, which is applied in the direction of motor vehicles, bicycle frames, motorcycles, etc., can solve the problem of difficulty in ensuring the length of welding lines, and achieve the effect of ensuring welding strength, easy welding and accurate welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

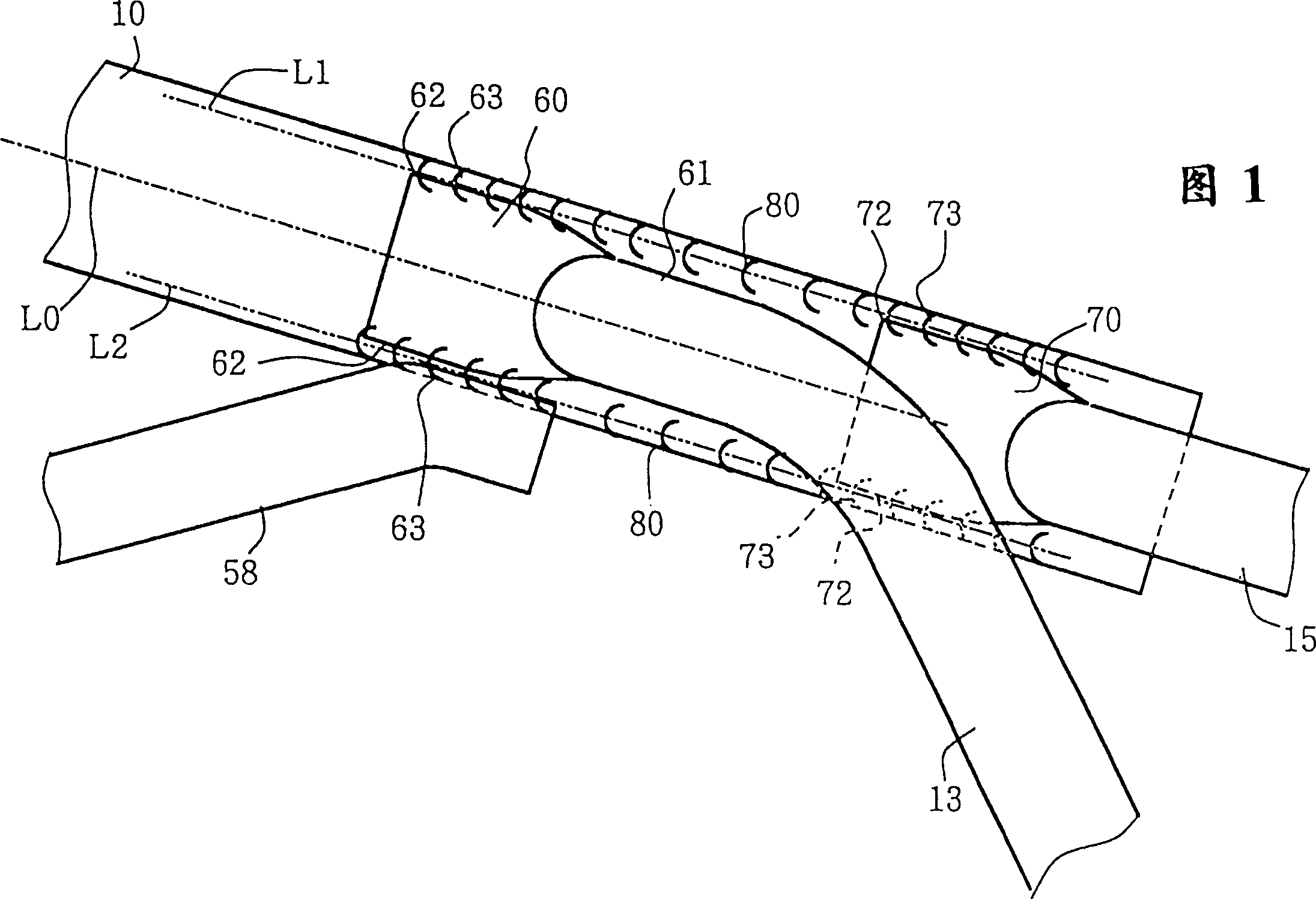

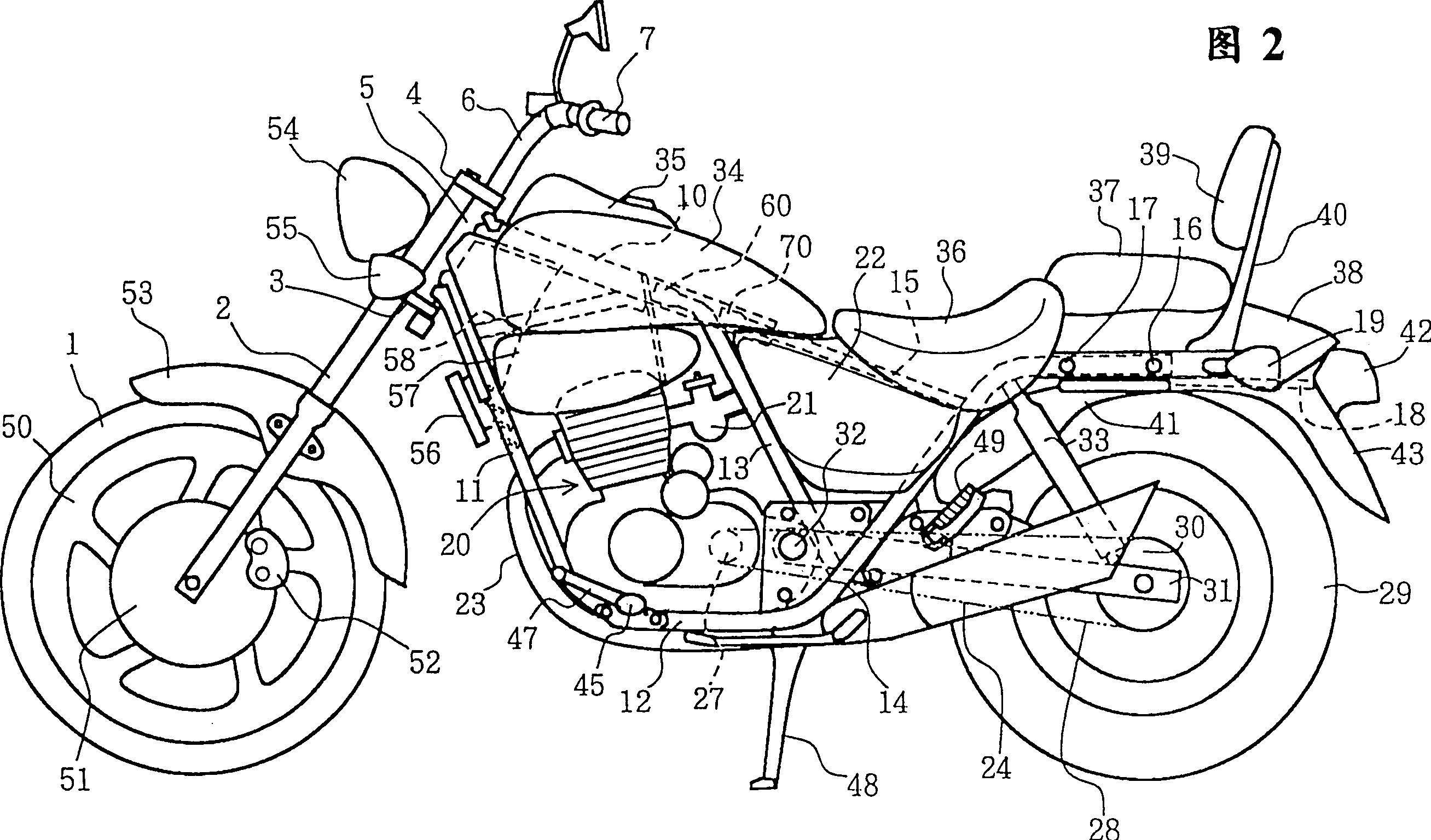

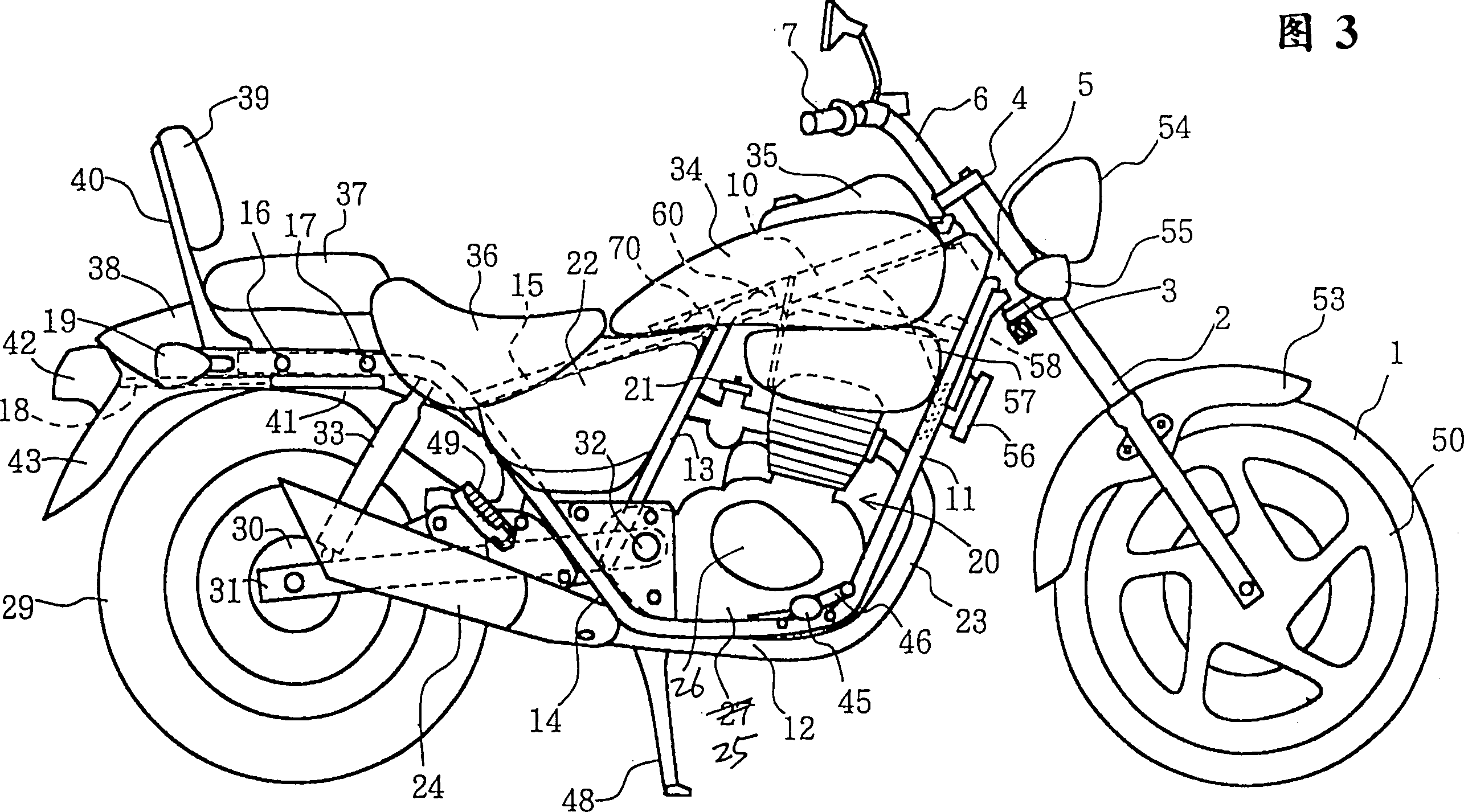

[0021] Next, an embodiment of the present invention configured as a specially manufactured motorcycle will be described with reference to the drawings. FIG. 1 is a side view showing a connection portion of a main frame, a seat rail, and a pivot frame. Fig. 2 is an overall left side view of the two-wheeled motor vehicle. Fig. 3 is an overall right side view of the two-wheeled motor vehicle. Fig. 4 is an overall side view of the vehicle frame. FIG. 5 is a top view of FIG. 1 .

[0022] As shown in Fig. 2 and Fig. 3, in this two-wheeled motor vehicle, the upper part of the front fork 2 supporting the front wheel 1 is rotatably supported on the head pipe 5 through the bottom connection fitting 3 and the top connection fitting 4, and the handle bar 6 is installed on the top connection fitting 4, and the position of its handle 7 is configured at the rear.

[0023] The head pipe 5 is mounted on the front end of the main frame 10. The main frame 10 extends forward and backward alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com