Stud assembly for connecting seat ring on pedestal pan

A toilet and upper seat technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of small space under the installation hole, inconvenient operation, time-consuming and laborious, etc., and achieve the effect of convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

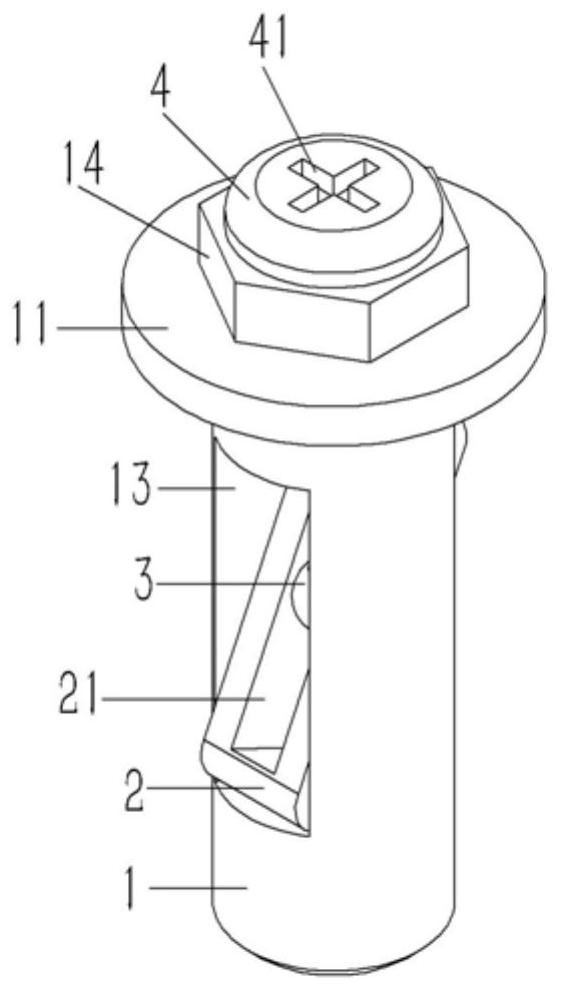

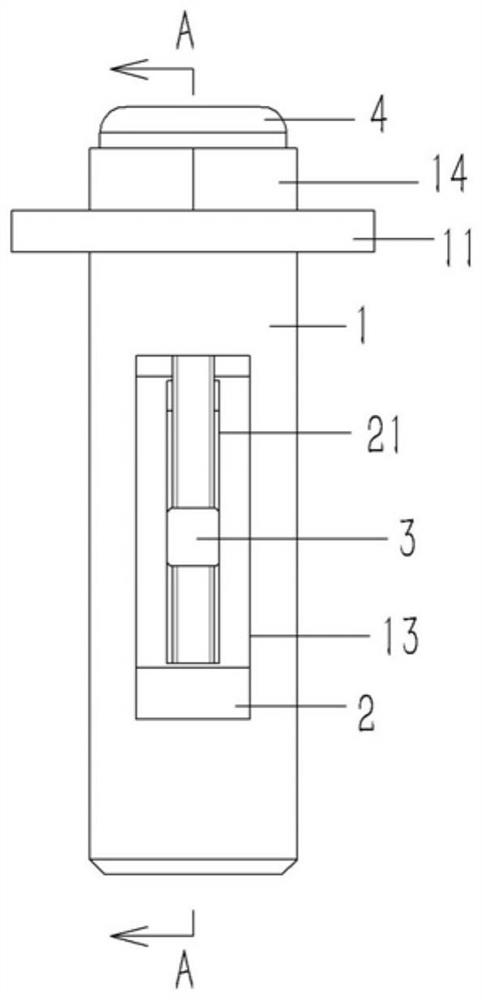

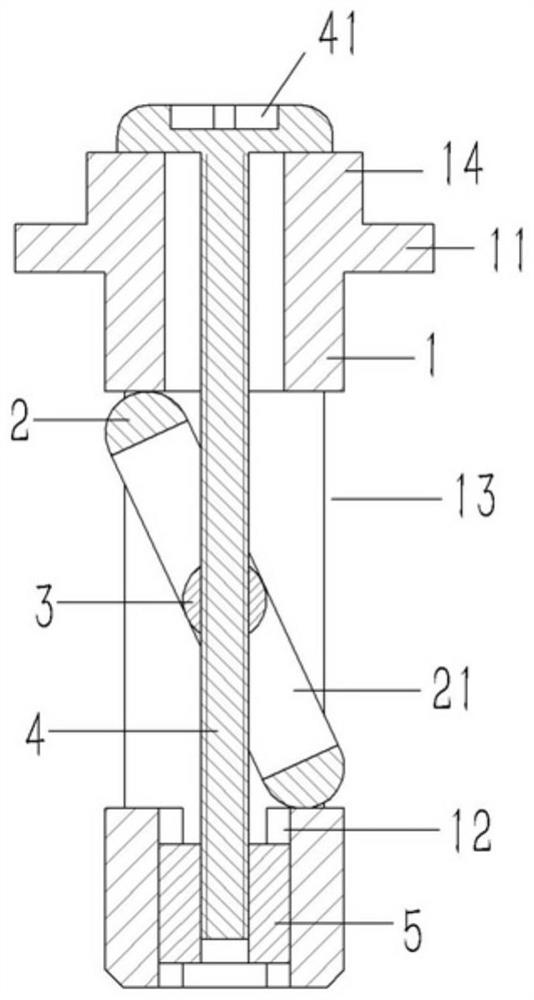

[0019] Example: see Figures 1 to 4 As shown, a stud assembly for connecting the upper seat ring of a toilet includes a vertical cannula 1, a retaining ring 11 is formed on the outer wall of the upper end of the cannula 1, and a lower end surface of the cannula 1 is formed with the inner wall of the cannula 1. A rectangular socket 12 with overlapping holes, the inner walls of the two opposite sides of the upper end of the rectangular socket 12 on the cannula 1 are formed with slots 13 that penetrate the outer wall of the cannula 1; the slots 13 of the cannula 1 are inserted obliquely. The limit stop bar 2, the middle of the limit stop bar 2 is formed with a strip-shaped slot hole 21 that penetrates the upper and lower end surfaces of the limit stop bar 2, and the strip-shaped slot hole 21 of the limit stop bar 2 is inserted into the spherical The positioning block 3, the two ends of the positioning block 3 are inserted on the inner side wall of the strip-shaped slot hole 21; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com