Electromagnetic clutch

An electromagnetic clutch and clutch technology, applied to clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve problems such as increased use costs, energy consumption, and long-time work of magnetic coils, and achieve energy saving and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solution of the present invention, the application will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the application. .

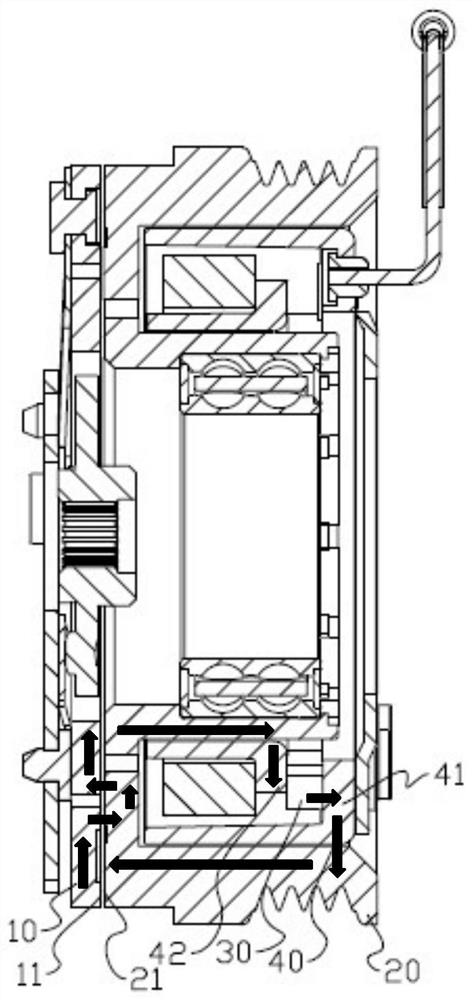

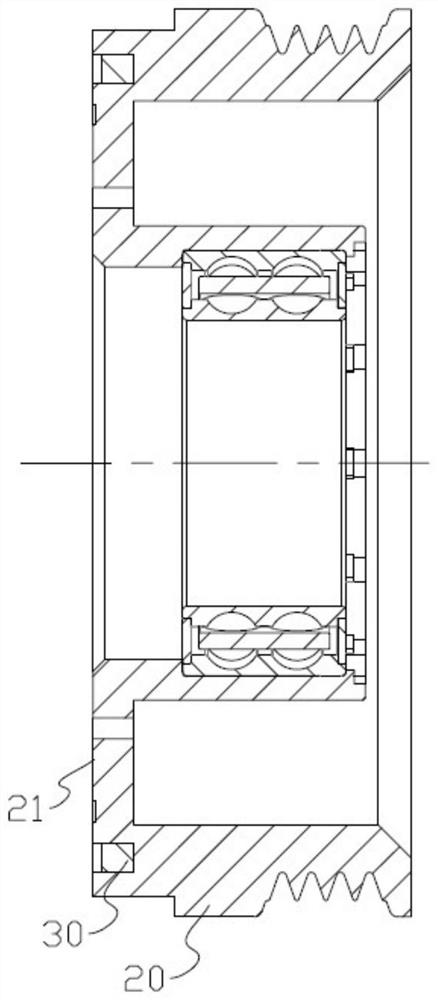

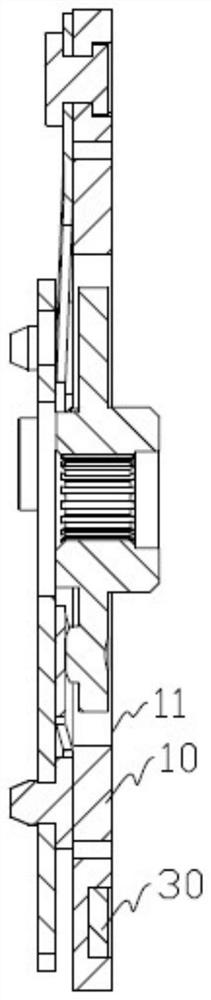

[0015] Such as figure 1 Shown is a schematic diagram of the first embodiment of the present application, including a drive disc assembly 10 and a pulley assembly 20, the pulley assembly 20 is provided with a coil assembly 40, and the drive disc assembly 10 or Several permanent magnets 30 are evenly distributed on the pulley assembly 20; the magnetic attraction force of the permanent magnets 30 is transmitted between the drive disk assembly 10 and the pulley assembly 20, so that the first drive disk assembly 10 adjacently arranged The friction surface 11 is engaged with the second friction surface 21 of the pulley...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap