Vertical push plate wave generation method and vertical push plate wave generation water tank

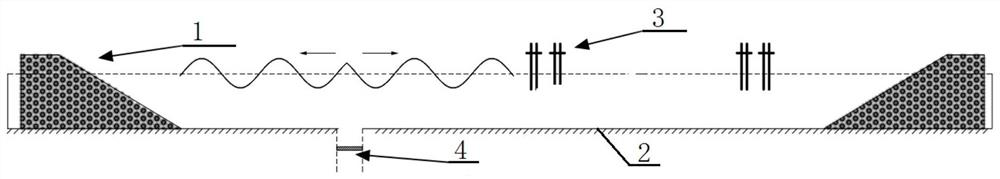

A push plate and vertical technology, which is applied in the field of vertical push plate wave making method and vertical push plate wave making tank, can solve problems such as difficult to realize and unable to make waves, so as to avoid secondary reflection and solve wave instability problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

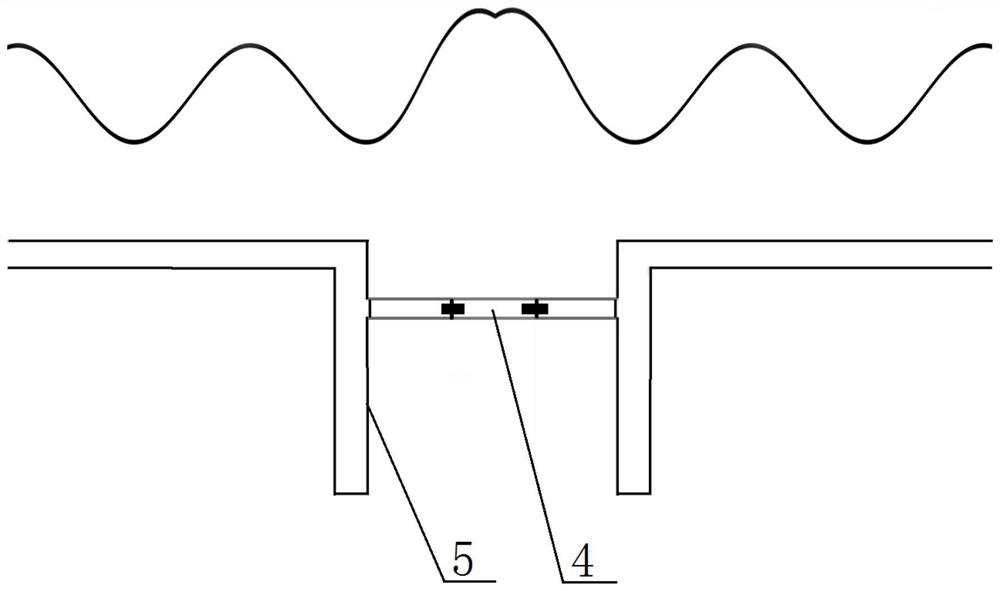

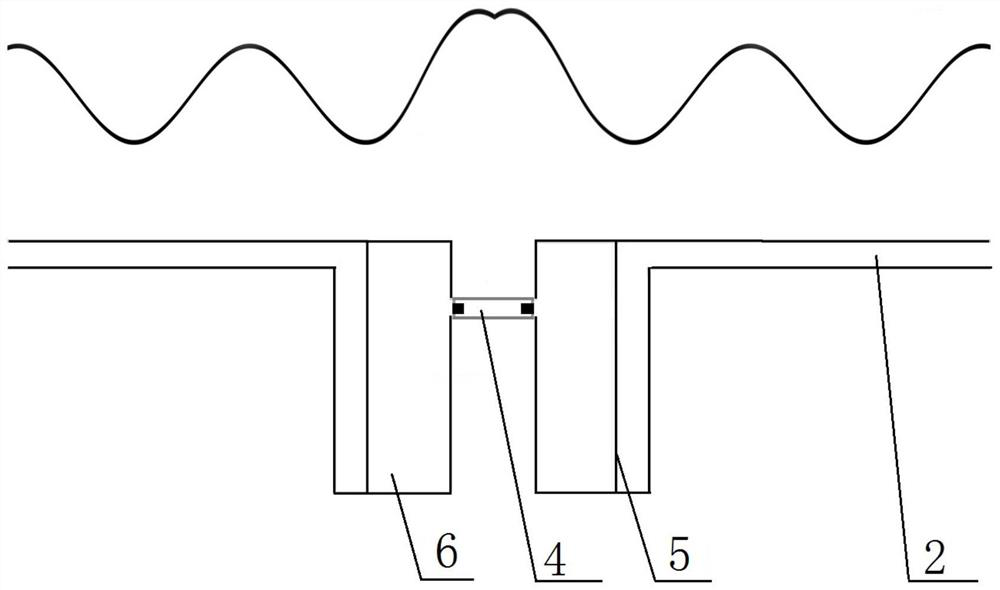

[0099] Such as Figure 4 to Figure 6 As shown, the push plate device of the vertical push plate wave-making tank in this embodiment includes side plate 13, bottom plate 12, partition plate 11 and vertical push plate 4, side plate 13 and partition plate 11 are arranged in parallel, and side Plate 13, dividing plate 11, two groove side plates 5 and bottom plate 12 form a closed cavity, vertical push plate 4 is arranged in this cavity, slides between vertical push plate 4 and the inner wall of groove side plate 5 Connected, the vertical push plate 4 can slide up and down along the groove side plate 5, the vertical push plate 4 cannot be higher than the sink bottom plate 2, and the bottom of the vertical push plate 4 is connected with the propulsion mechanism. The outside of dividing plate 11 is provided with water tank 8, and the bottom end of dividing plate 11 is provided with communicating hole 9, and the cavity below vertical push plate 4 is communicated with water tank 8 by c...

Embodiment 2

[0102] The connector in this embodiment adopts a conduit, and fluid is contained in the conduit, and the conduit communicates with the cavity below the vertical push plate through the communication hole at the bottom of the propulsion device. By controlling the amount of fluid in the conduit and the height of the conduit, and then controlling the pressure in the conduit, through the reciprocating movement of the fluid in the conduit, the flow direction of the fluid in the cavity below the vertical push plate is changed, thereby changing the movement of the vertical push plate direction, and finally achieve wave making.

[0103] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com