High-voltage electrostatic protection structure

A technology for protecting structures and high-voltage static electricity, which is applied to circuits, electrical components, and electric solid devices, etc., can solve problems such as large latch-up risks, and achieve the effect of improving antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

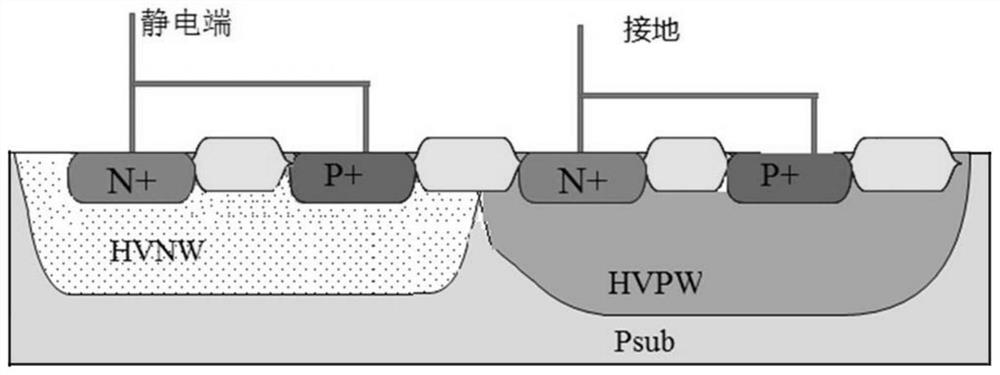

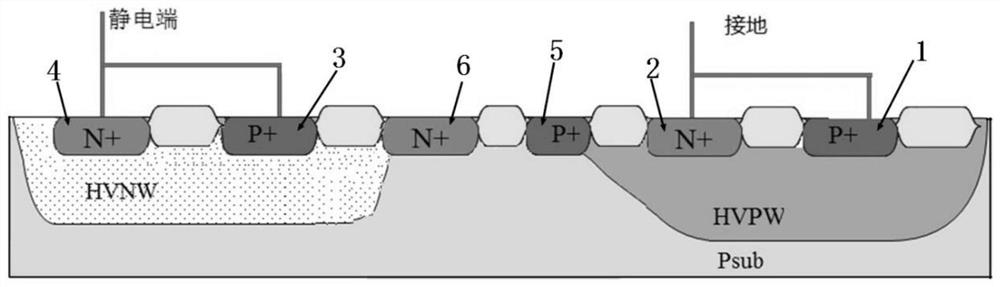

[0037] The high-voltage electrostatic protection structure described in the present invention, such as image 3 As shown, a high-voltage SCR structure is formed, with a high-voltage N-well (HVNW) and a high-voltage P-well (HVPW) on a P-type substrate. The two are separated by a certain distance by the substrate, whose sides are not in contact with each other.

[0038] The high-voltage P well includes a P+ doped region (the first heavily doped region) and an N+ doped region (the second heavily doped region), and a field oxygen is separated between the P+ doped region and the N+ doped region, Wherein the N+ doped region is close to the central region of the SCR structure; the high-voltage N well includes an N+ doped region (the fourth heavily doped region) and a P+ doped region (the third heavily doped region), between the two A section of field oxygen is also spaced between them, wherein the P+ doped region is close to the central region of the SCR structure.

[0039] The sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com