High-voltage electrostatic protection structure

A high-voltage electrostatic and protective structure technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems such as inability to turn them off, and achieve the effect of improving antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

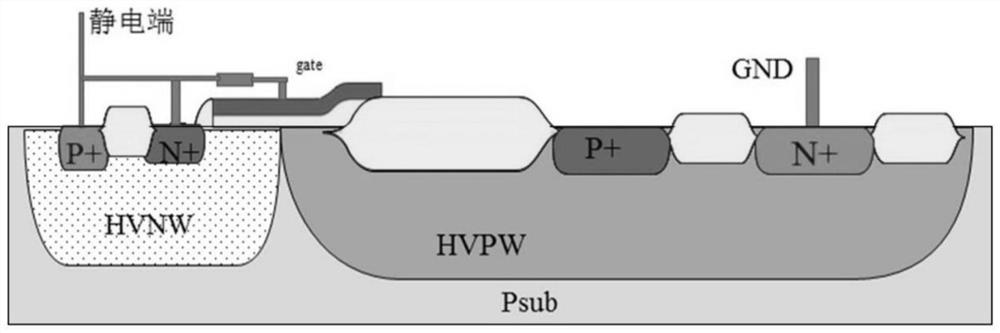

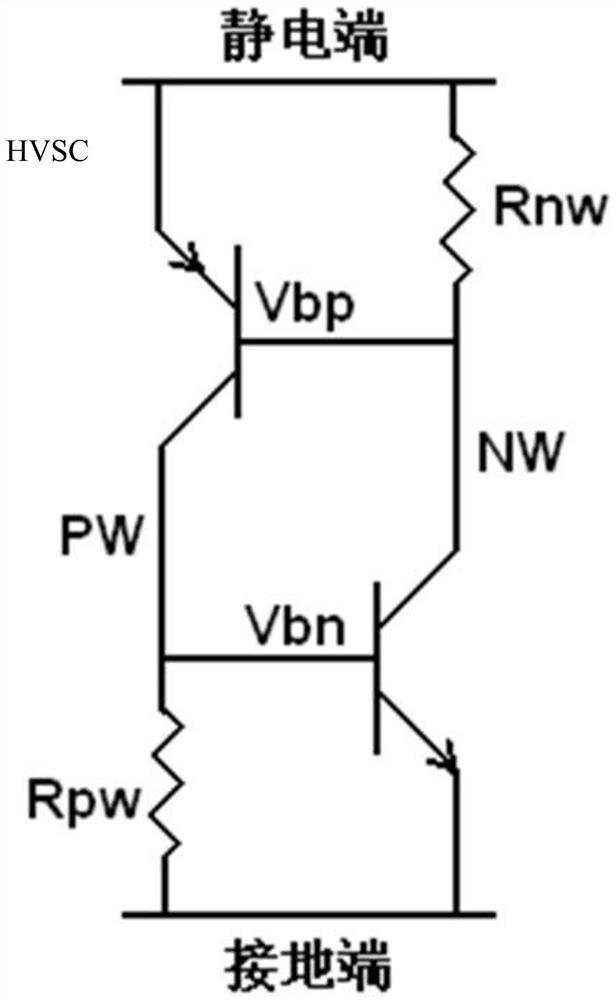

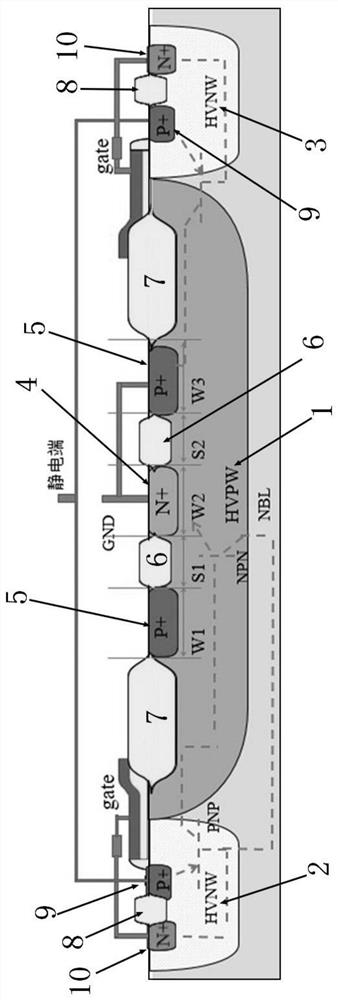

[0052] like image 3 As shown, the structure is located on an N-type buried layer NBL in a P-type substrate.

[0053] In section, the high-voltage electrostatic protection has a left-right symmetrical structure, including a P-type high-voltage well 1 located in the central region, and N-type high-voltage wells 2 and 3 located on both sides of the high-voltage well 1.

[0054] In the high-voltage well 1, the central region has an N-type heavily doped region 1, and the two sides of the heavily doped region 1 are symmetrically arranged in sequence with the first field oxygen, the P-type heavily doped region 2, and the second field. oxygen.

[0055] In the high-voltage well two, there is a source region of an LDMOS device, and an N-type heavily doped region three leading out the high-voltage well two, and a third field oxygen is separated between the source region and the heavily doped region three ;

[0056] The substrate surface between the high-voltage well 2 and the high-vo...

Embodiment 2

[0065] The second embodiment provides another high-voltage electrostatic protection structure, which increases the number of heavily doped regions in the high-voltage well at the drain end on the basis of the first embodiment. like Figure 5 As shown, the main difference lies in the structure of the high-voltage well 4, that is, the arrangement of the heavily doped region in the high-voltage well at the drain end, Figure 5 Middle-drain end high-voltage P well High-voltage well four The heavily doped region four located in the central region is P-type, and the fourth field oxygen, the heavily doped region five (N+), and the fifth field are symmetrically arranged in sequence on both sides around it. Oxygen, heavily doped region six (P+) and sixth field oxygen.

[0066] In cross-section, the high-voltage electrostatic protection has a left-right symmetrical structure, including a high-voltage well 4 of the first conductivity type located in the central area, and high-voltage we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com