Dehumidification equipment for power equipment

A technology for power equipment and equipment, applied in lighting and heating equipment, substation/distribution device casings, dry solid materials, etc., to avoid residual moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

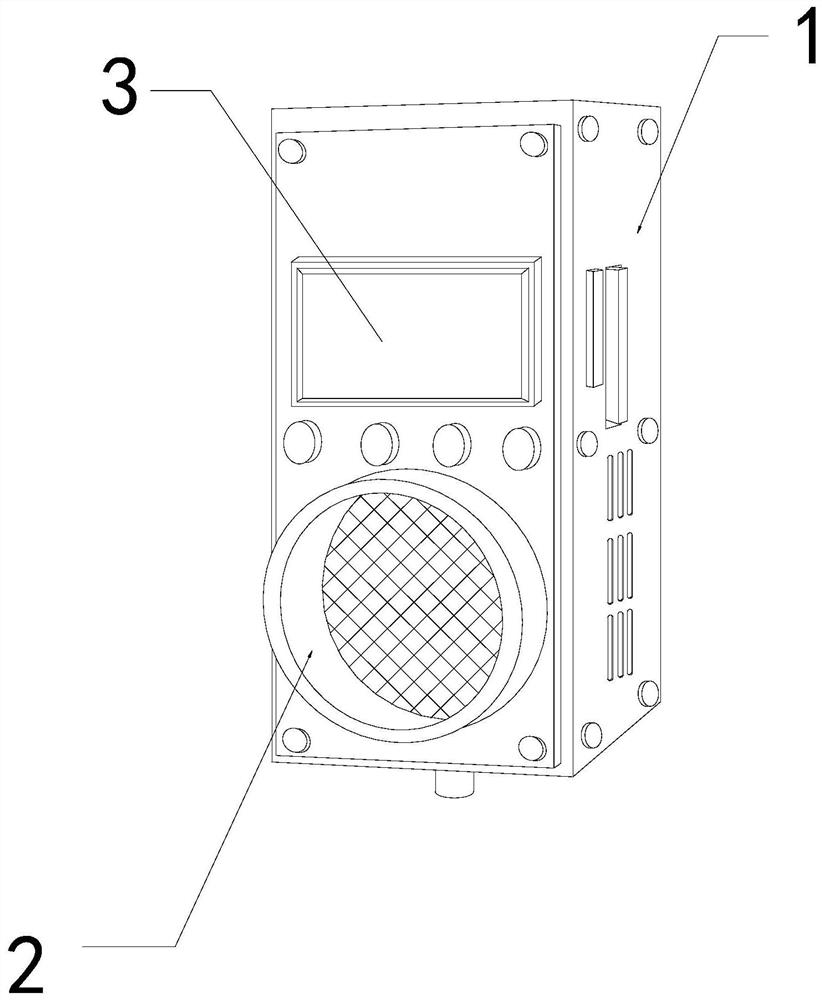

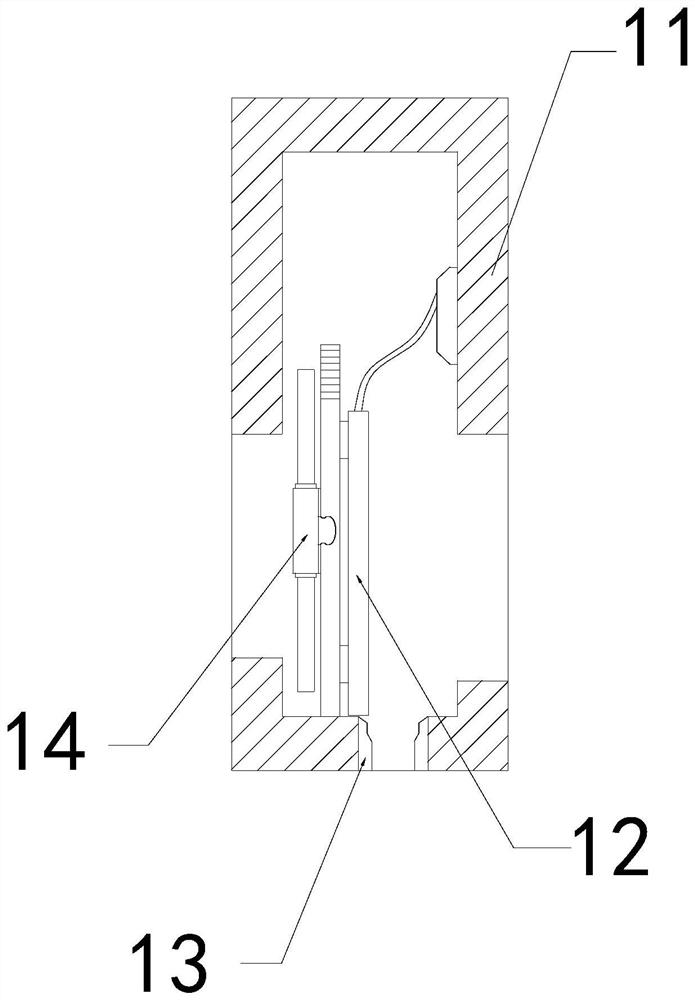

[0027] The invention provides a dehumidification equipment for electric power equipment, the structure of which includes a body 1, an exhaust pipe 2, and a control panel 3. The control panel 3 is embedded and fixed at the front end of the body 1, and the body 1 and the exhaust pipe 2 are integrated. structure; the body 1 includes an outer frame 11, a condensation plate 12, a water outlet 13, and an exhaust fan 14, the condensation plate 12 is installed on the right side of the exhaust fan 14, and the water outlet 13 is integrated with the outer frame 11 structure, the exhaust fan 14 is movably engaged with the outer frame 11.

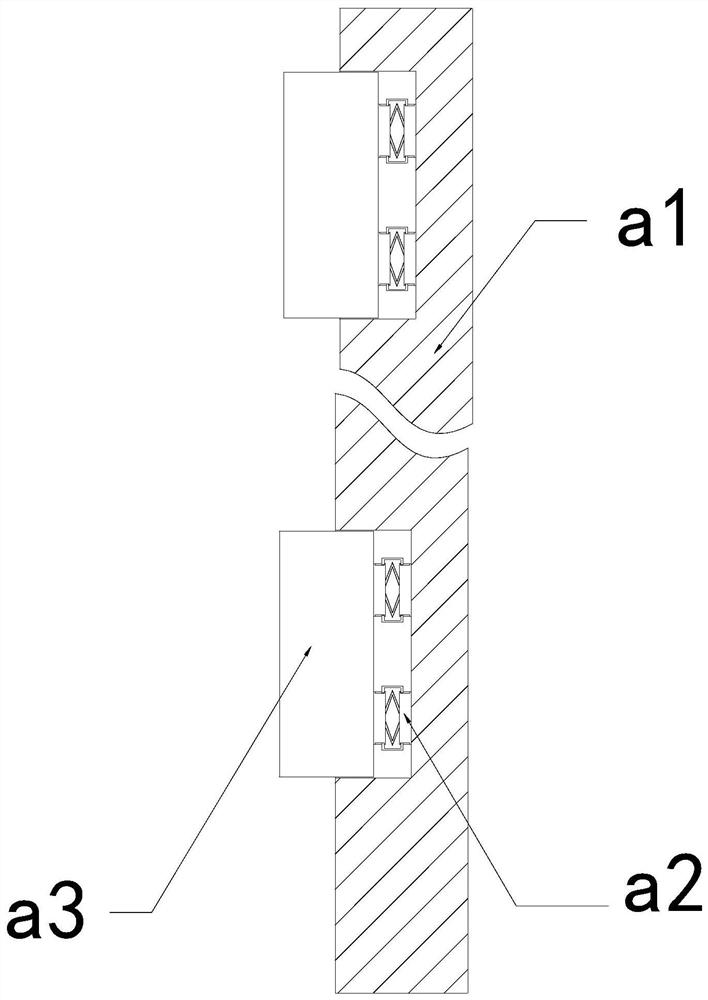

[0028] Wherein, the condensation plate 12 includes a blocking plate a1, an elastic frame a2, and a guide block a3, and the elastic frame a2 is installed between the right side of the inner wall of the blocking plate a1 and the right side of the guide block a3, and the guide block a3 and the right...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the water outlet 13 includes an elastic bar c1, an upper slide plate c2, and a frame c3, the elastic bar c1 is installed between the upper slide plate c2 and the frame body c3, and the inner side of the upper slide plate c2 and the elastic bar c1 is movable. In combination, there are two upper slides c2, which are evenly distributed symmetrically inside the elastic strip c1, and the outward suction is generated by the rotation of the mechanism, which can make the upper slide c2 slide upward along the frame c3, so that the entry The moisture in the frame c3 can be discharged downward along the upper slide plate c2.

[0036] Wherein, the upper sliding plate c2 includes a squeeze roller c21, a deformation surface c22, a receiving plate c23, and a booster block c24. On the right side of the receiving plate c23, the booster block c24 is installed on the left side of the inner wall of the receiving plate c23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com