Full-automatic grain screening device

A fully automated, sieving technology, applied in the field of grain processing, can solve the problems of insufficient sieving, doping with impurities, poor screening effect, etc., and achieve the effect of easy popularization and application and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

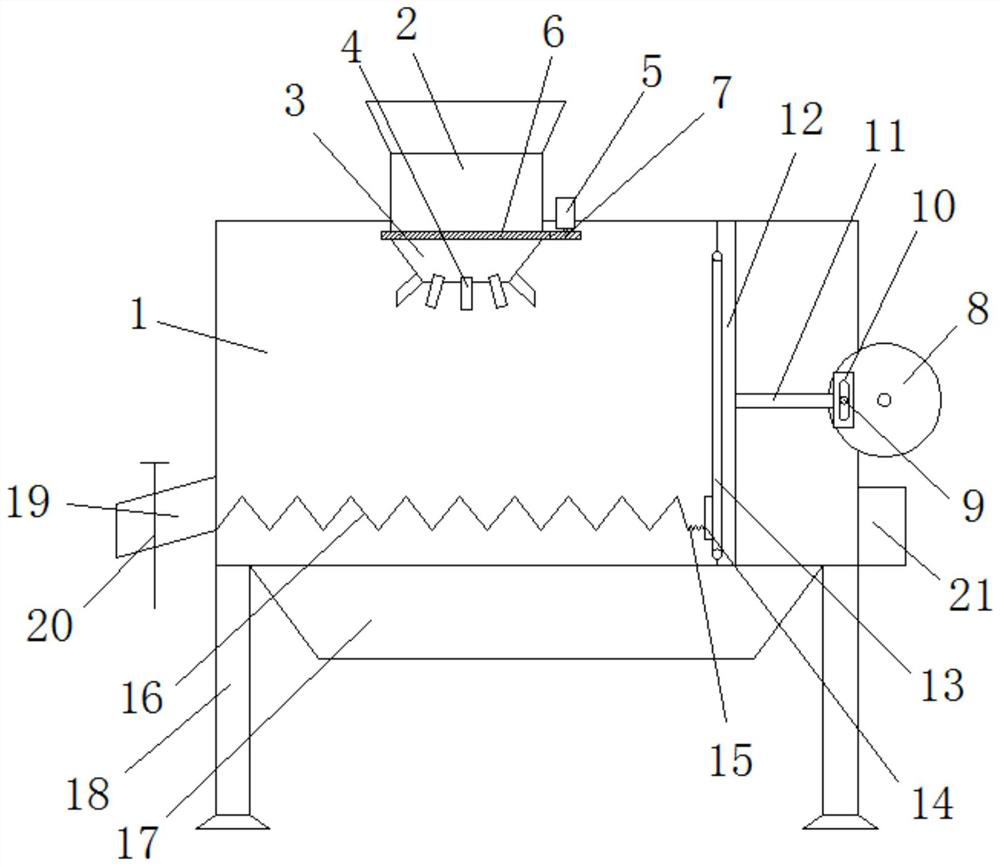

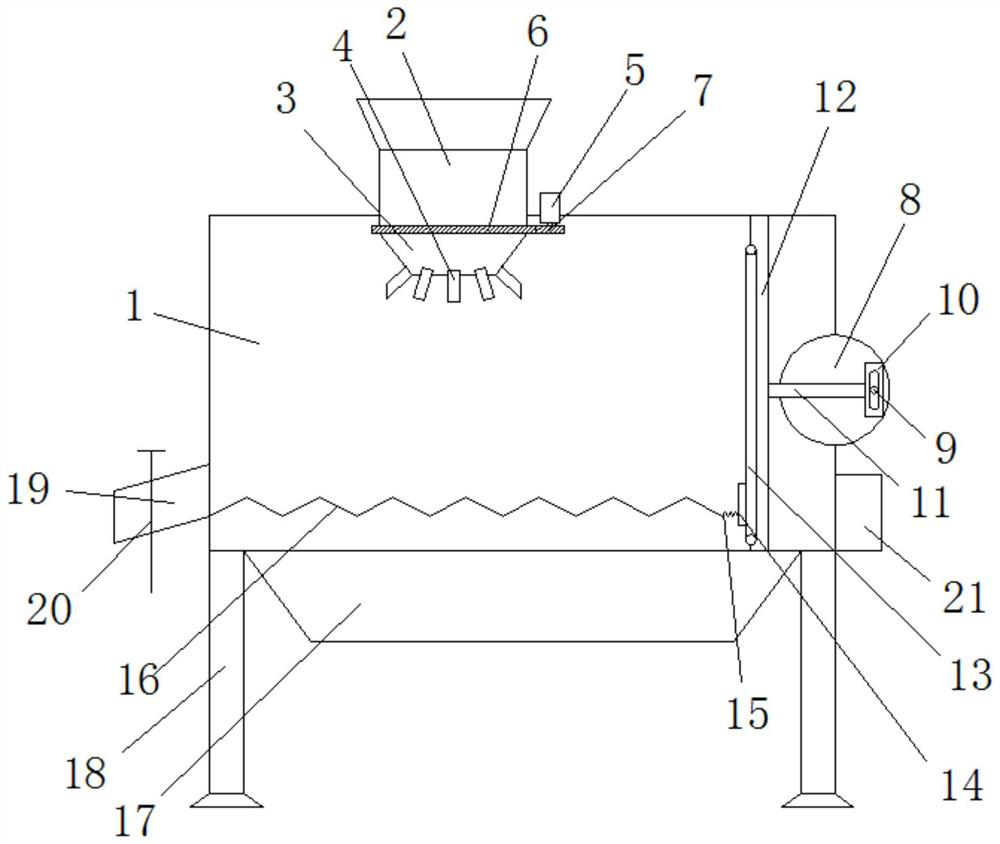

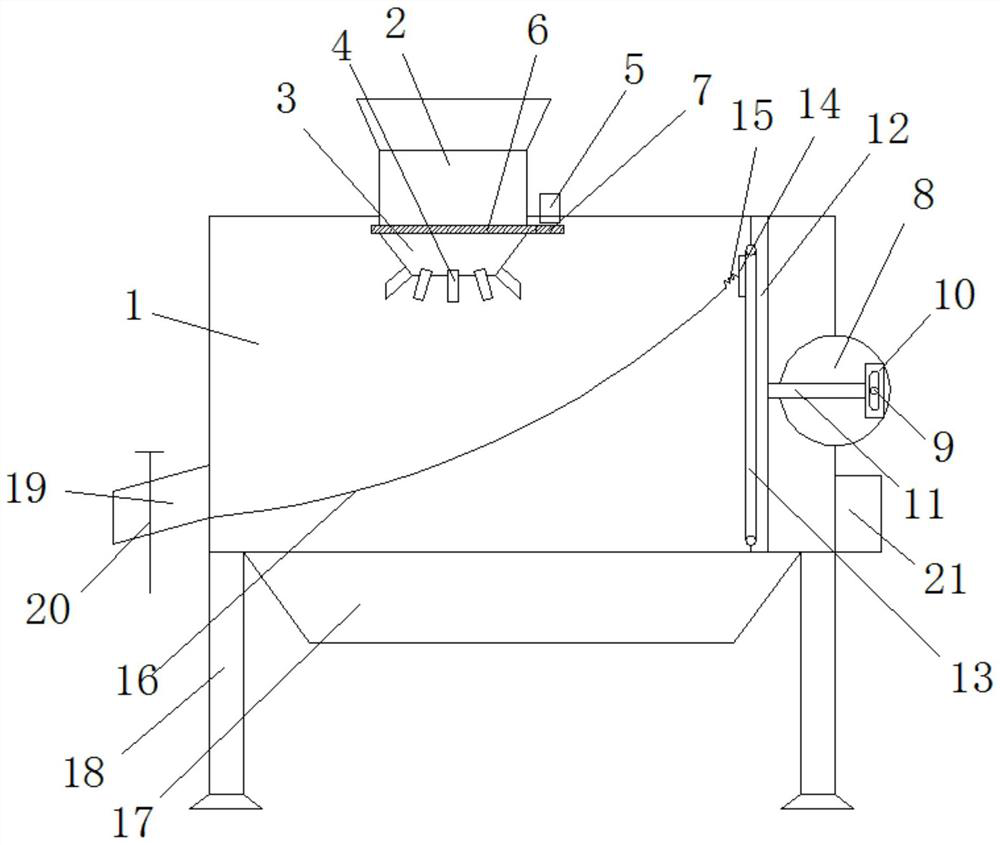

[0020] Embodiment 1: as Figure 1-4 Shown, a kind of fully automatic grain sorting device comprises sub-sieving bin 1, and the top of described sub-sieving bin 1 is fixedly equipped with feeding hopper 2;

[0021] The material is introduced into the sub-screen bin through the feed hopper, and falls to the upper surface of the screen of the sub-screen bin.

[0022] A second motor 21 is fixedly installed on the right side of the sieve bin 1, a reciprocating plate 12 is movably connected to the right part of the inner cavity of the sieve bin 1, and a turntable 8 is connected to the right side of the sieve bin 1 for rotation. The edge of the side wall of the turntable 8 is fixedly connected with a clamp shaft 9, the right side of the reciprocating plate 12 is fixedly connected with a connecting rod 11, and the right side of the connecting rod 11 is fixedly connected with a clamping plate 10, and the clamping plate 10 A through slot is opened inside, and the clamp shaft 9 is engag...

Embodiment 2

[0030] Embodiment 2: as Figure 1-4 Shown, a kind of fully automatic grain sorting device comprises sub-sieving bin 1, and the top of described sub-sieving bin 1 is fixedly equipped with feeding hopper 2;

[0031] The material is introduced into the sub-screen bin through the feed hopper, and falls to the upper surface of the screen of the sub-screen bin.

[0032] A second motor 21 is fixedly installed on the right side of the sieve bin 1, a reciprocating plate 12 is movably connected to the right part of the inner cavity of the sieve bin 1, and a turntable 8 is connected to the right side of the sieve bin 1 for rotation. The edge of the side wall of the turntable 8 is fixedly connected with a clamp shaft 9, the right side of the reciprocating plate 12 is fixedly connected with a connecting rod 11, and the right side of the connecting rod 11 is fixedly connected with a clamping plate 10, and the clamping plate 10 A through slot is opened inside, and the clamp shaft 9 is engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com