Rubber powder vibrating screen

A technology of rubber powder and vibrating screen, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of material accumulation and material blocking, and achieve the effect of preventing accumulation and blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

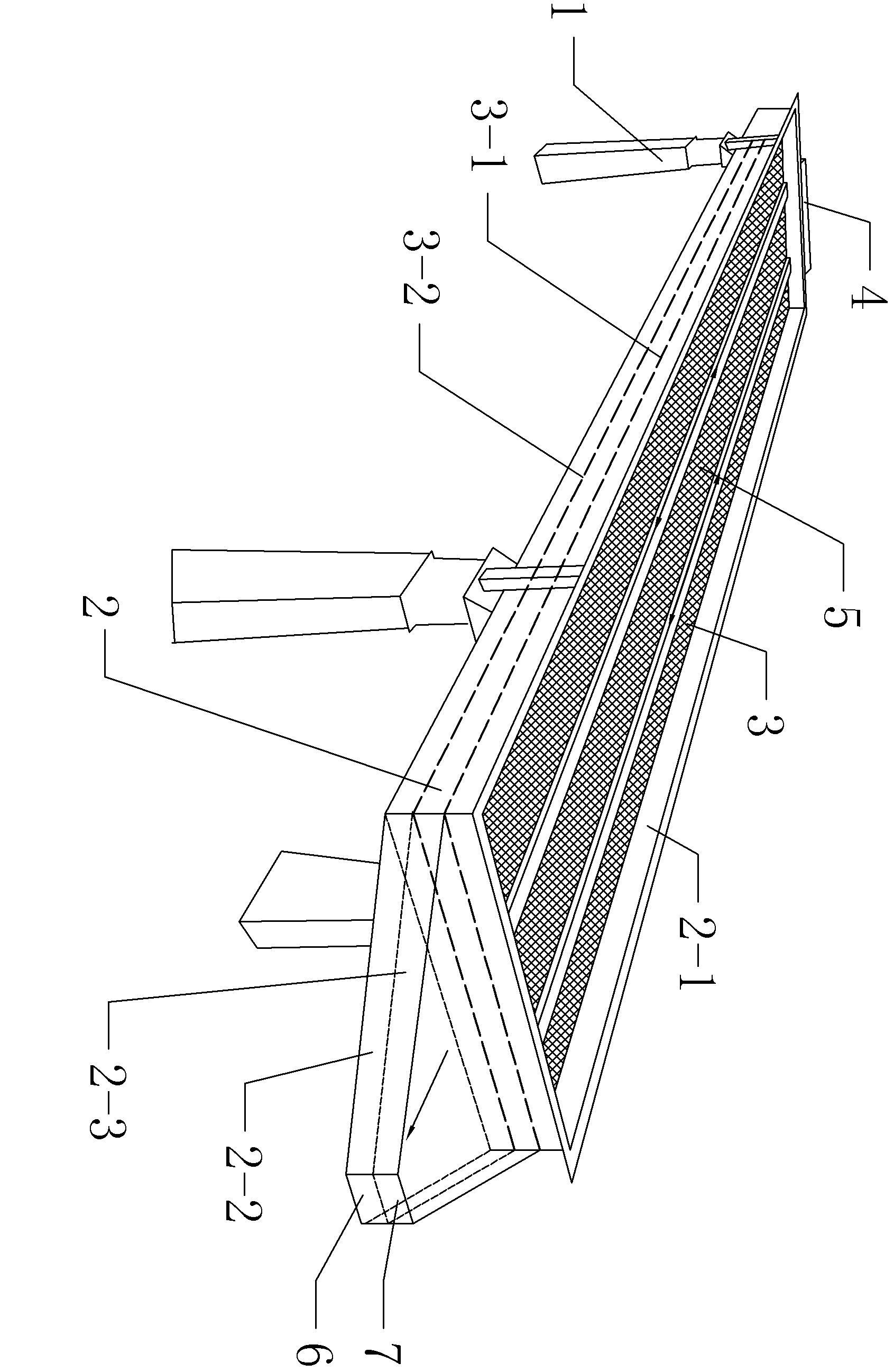

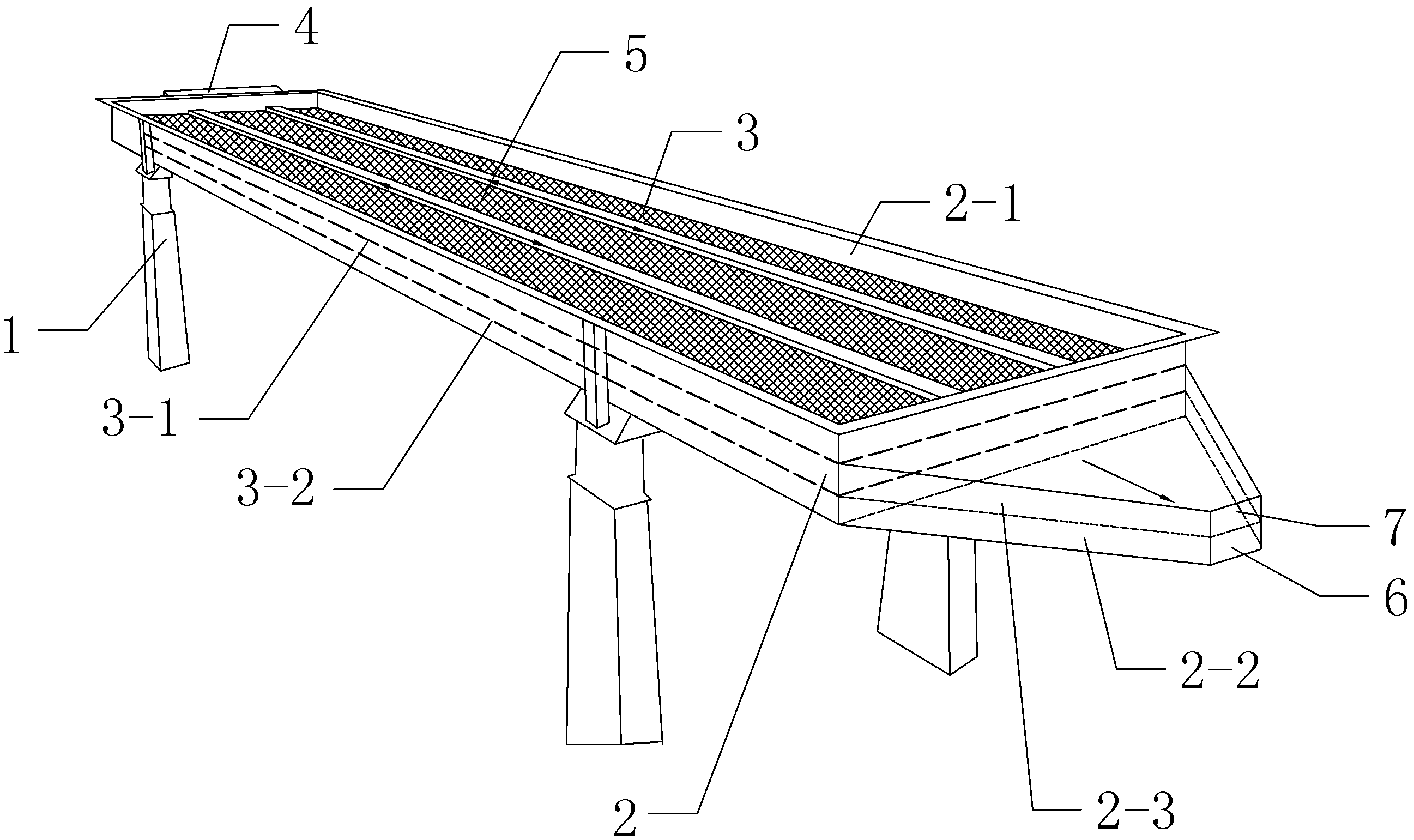

[0023] A rubber powder vibrating sieve such as figure 1 As shown, it mainly consists of frame (1), screen box (2), screen cloth (3) and vibrating motor (4). The screen box (2) is arranged on the frame (1), and the two are connected by a spring support. The screen box (2) includes two connected cavities, the vibration cavity (2-1) and the discharge cavity (2-2), wherein the vibration cavity (2-1) is a flat hollow square, and the discharge cavity (2- 2) is a flat hollow V shape. The discharge cavity (2-2) is connected on the side wall of the oscillation cavity. The upper part of the vibration chamber (2-1) is provided with a sieve box inlet (5) for the materials to be screened to be fed into the sieve box (2), and the lower part of the discharge chamber (2-2) is provided with a sieve box outlet ( 6) Export the finished material out of the screen box (2). The screen (3) is horizontally arranged in the vibration cavity of the screen box (2), and the vibration cavity (2-1) is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com