Intelligent screening device for fertilizers

A screening device and intelligent technology, applied in the direction of screening, solid separation, grille, etc., can solve the problems of easy accumulation of fertilizers, insufficient screening, affecting product quality and pass rate, etc., to prolong the service life and speed up screening Sub-rate, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

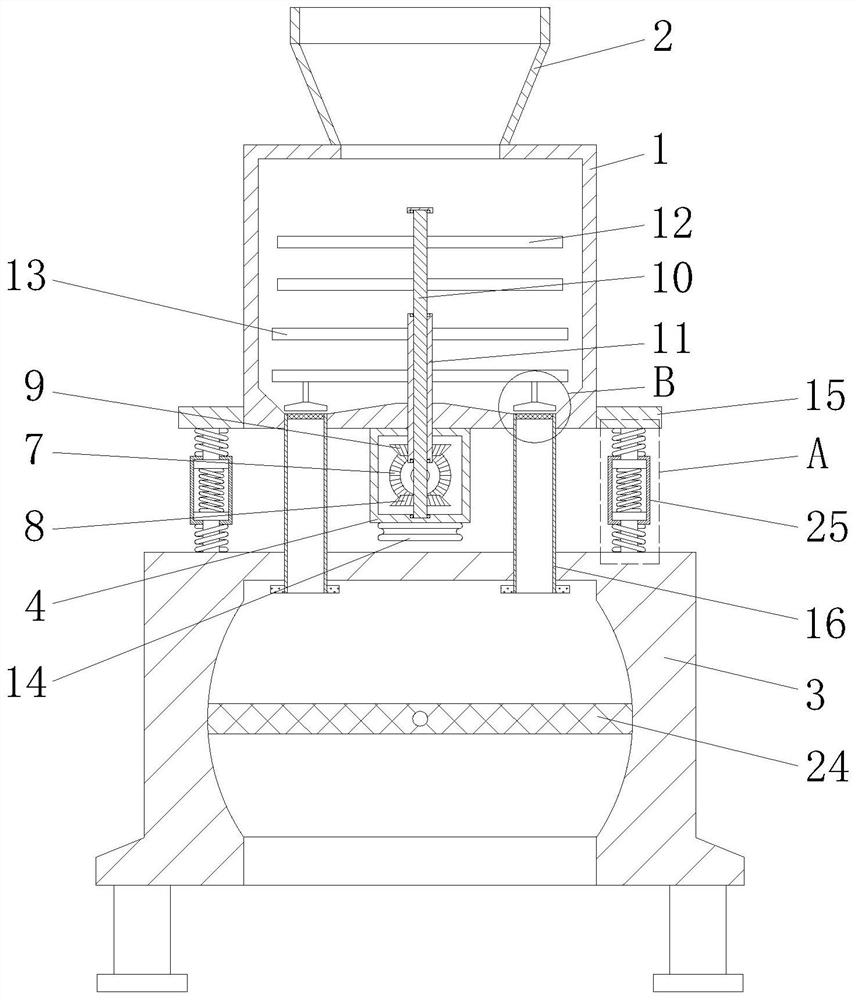

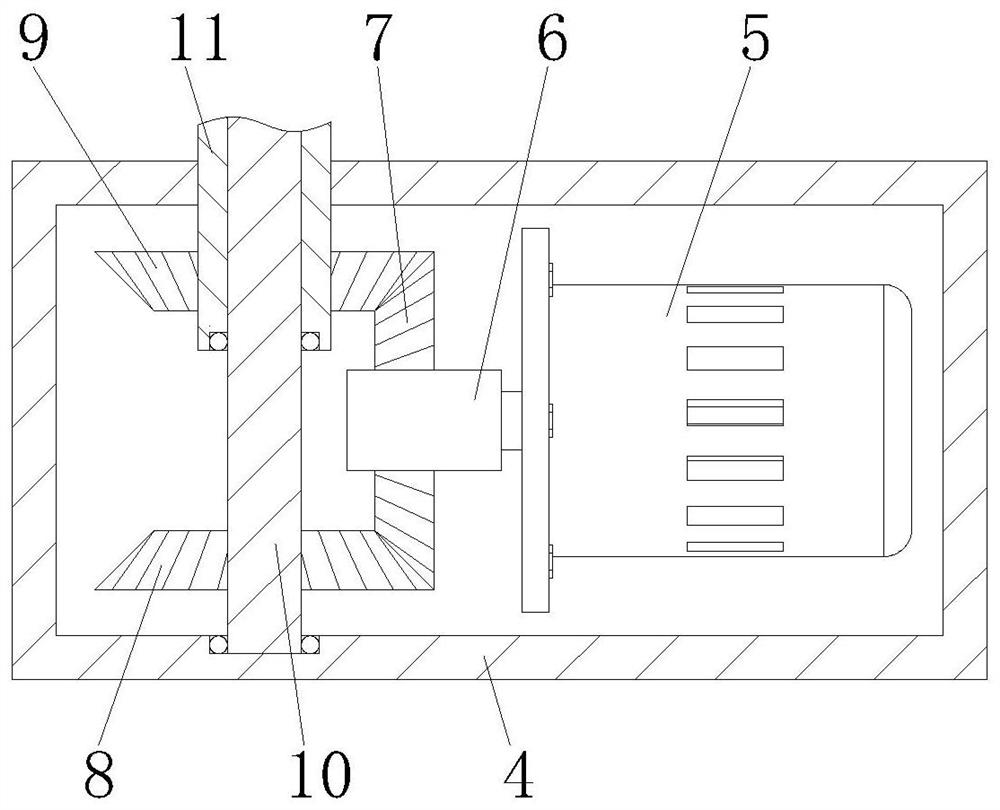

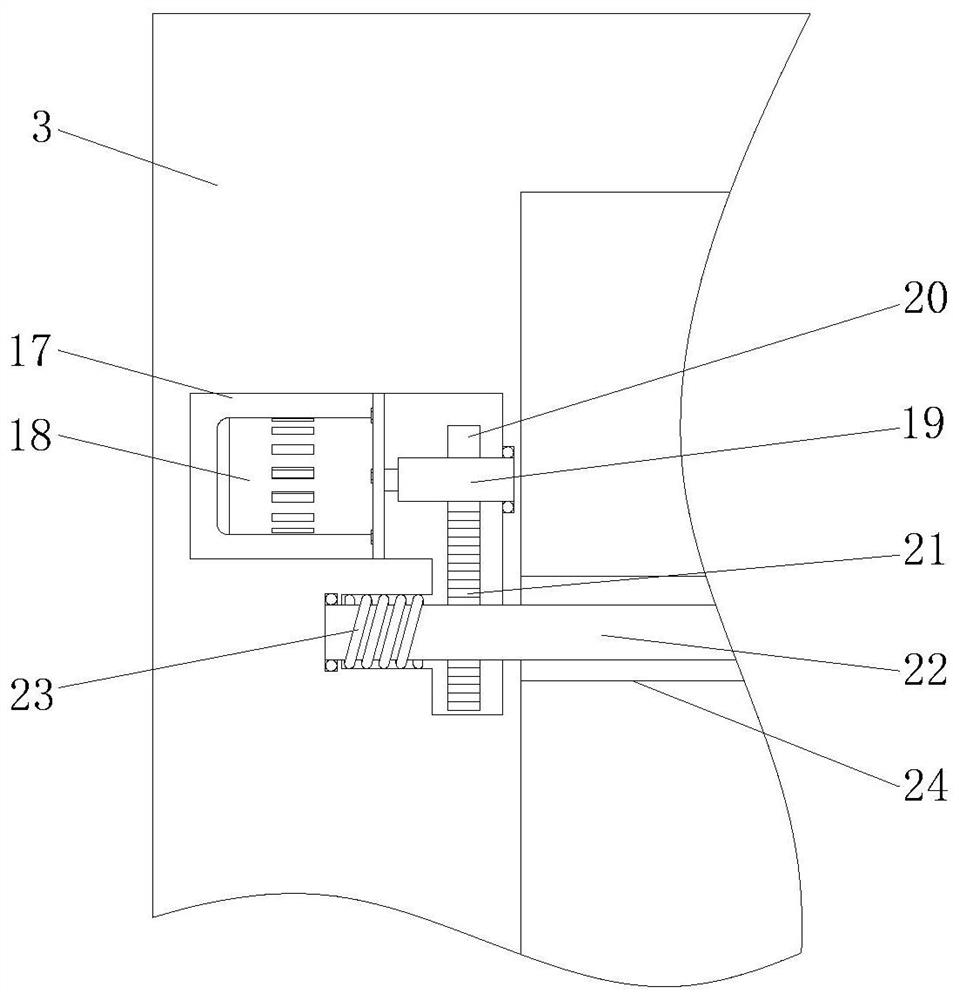

[0028] see Figure 1-7As shown, an intelligent screening device for fertilizers includes a crushing cylinder 1 and a screening cylinder 3, the crushing cylinder 1 is fixed on the top of the screening cylinder 3 through a cushioning support assembly, and the inside of the crushing cylinder 1 The chamber communicates with the inner chamber of the screening cylinder 3 through the discharge pipe 16, and the top end surface of the crushing cylinder 1 is fixedly connected with a discharge hopper 2, and the inner chamber of the crushing cylinder 1 is provided with a crushing assembly, and the crushing cylinder 1 The bottom is provided with a power output assembly, and the power output assembly is connected with the crushing assembly through a transmission assembly. An installation chamber 17 is provided in the screening cylinder 3, and a motor two 18 is fixedly installed in the installation chamber 17. The motor two The output end of 18 is fixedly connected with the second rotating s...

Embodiment 2

[0037] see Figure 8 As shown in Comparative Example 1, as another embodiment of the present invention; the front end surface and the rear end surface of the control box 4 are provided with several cooling holes 31, and several of the cooling holes 31 are in a rectangular array. The form is distributed on the front side and the back side of the control box 4; when working, the heat generated by the motor 15 can be discharged from the control box 4 in time through the several cooling holes 31 provided on the front side and the back side of the control box 4 , so that the air in the inner cavity of the control box 4 can circulate, ensuring that the temperature in the control box 4 is suitable, and providing a good working environment for the motor one 5.

[0038] The working principle is that the staff puts the fertilizer into the inner cavity of the crushing cylinder 1 through the drop hopper 2, and drives the rotating shaft 6 to rotate through the motor 1 5, so that the bevel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com