Fine sand screening and quantitative bagging integrated device

A quantitative bagging and fine sand technology, applied in sieves, packaging, solid materials, etc., can solve the problems of reducing work efficiency, cumbersome operations, and increasing workload, saving manpower and time, facilitating data statistics, and speeding up The effect of screening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

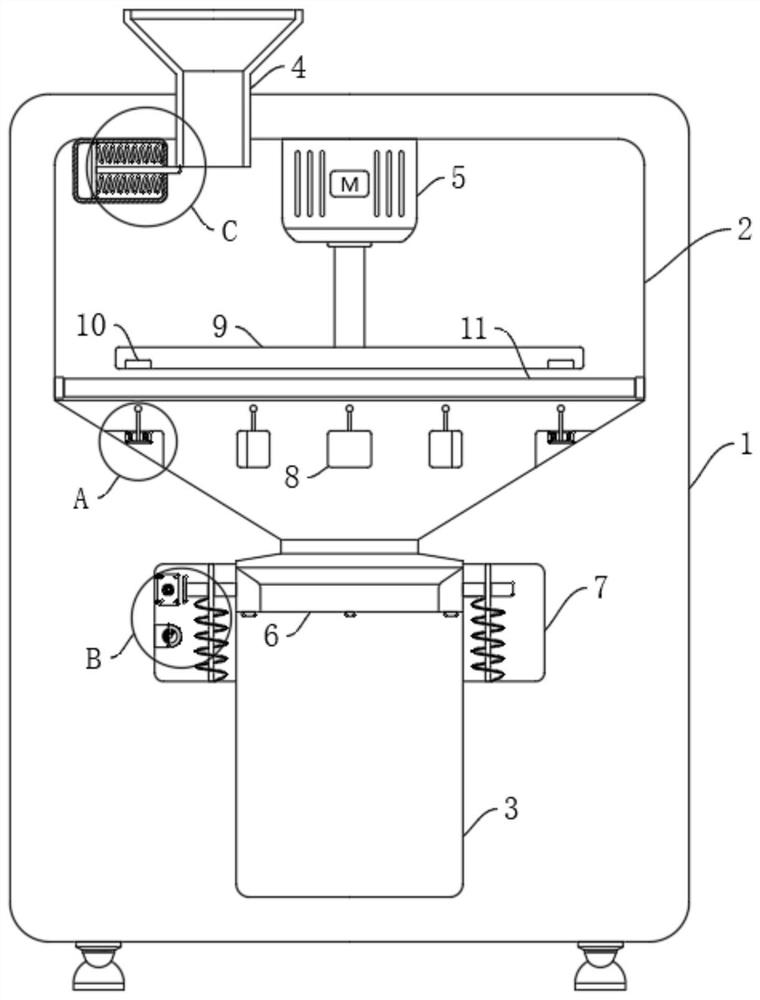

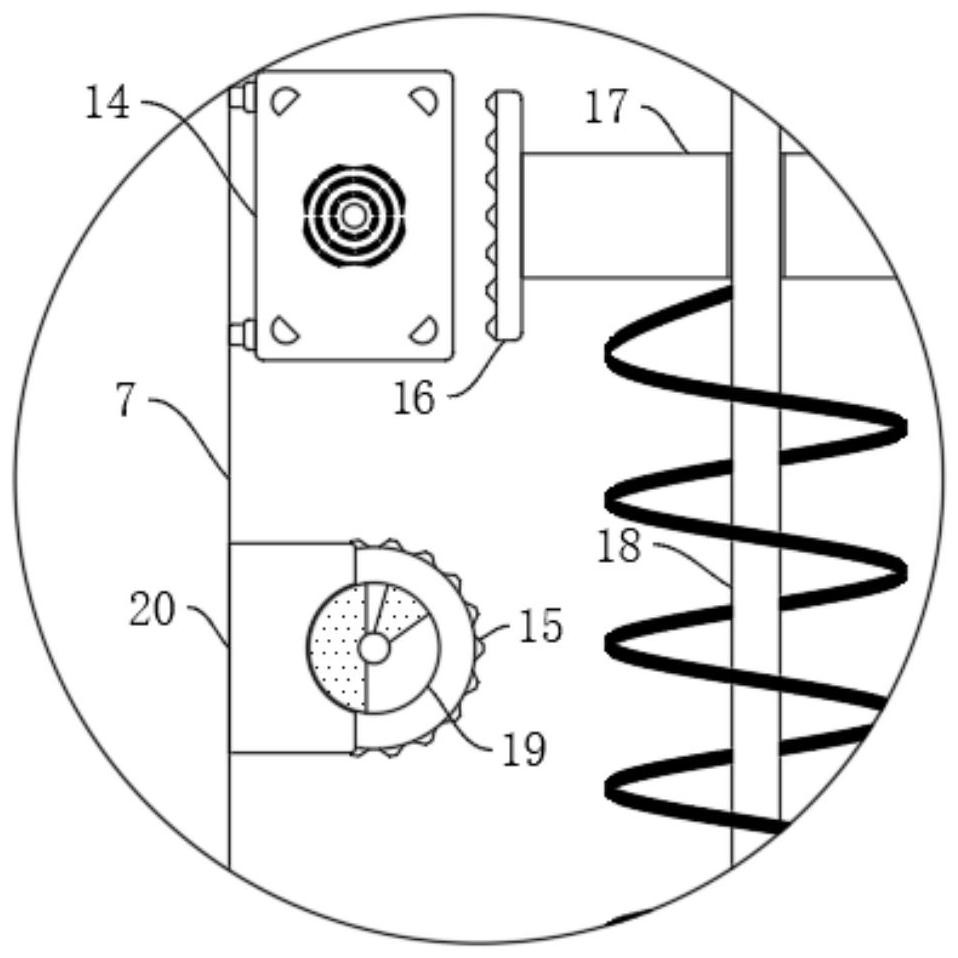

[0029] refer to Figure 1-4 , an integrated device for fine sand screening and quantitative bagging, comprising a body 1, the upper wall of the body 1 is connected with a sand inlet pipe 4, the sand inlet pipe 4 is funnel-shaped, and the lower end of the sand inlet pipe 4 extends to the inside of the body 1, The body 1 is equipped with a screening chamber 2 and a collection chamber 3, the screening chamber 2 and the collection chamber 3 are connected, the space near the upper end of the screening chamber 2 is a cylindrical structure, and the space near the lower end of the screening chamber 2 is a circular frustum structure, which is set in a circular frustum shape It is convenient for the screened sand to slide into the collection bin 3 along the inclined plane, and the space of the collection bin 3 is a cylindrical structure.

[0030] There is a screening mechanism inside the screening chamber 2, the screening mechanism includes a motor 5 fixedly connected to the top of the ...

Embodiment 2

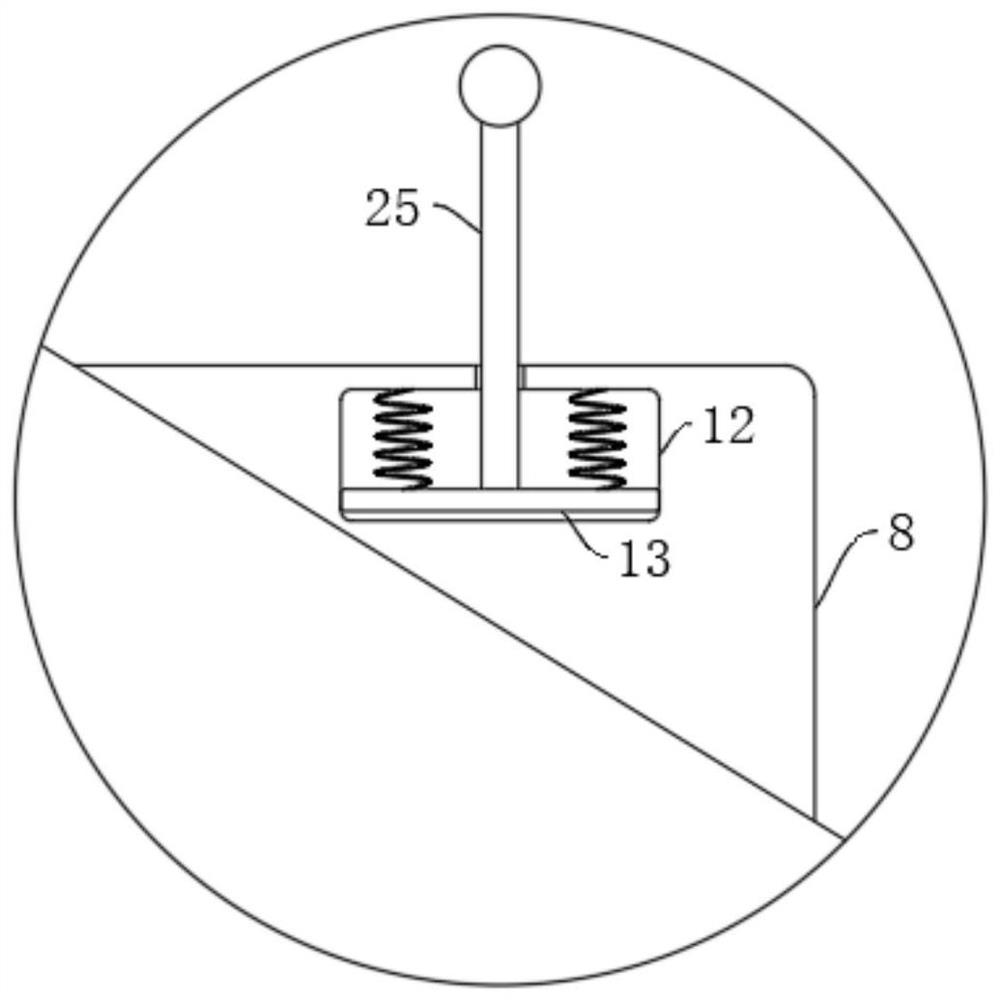

[0040] refer to Figure 5-6 , an integrated device for fine sand screening and quantitative bagging, a plurality of metal plates 13 are respectively sealed and slidingly connected with the inner walls of the corresponding placement chambers 12, and air bags 24 are fixedly connected to the upper walls of the plurality of fixed blocks 8, and the plurality of air bags 24 are respectively It communicates with the corresponding placement cavity 12 .

[0041] Compared with Embodiment 1, in this embodiment, when the metal plate 13 moves up, the air in the placement chamber 12 can be squeezed into the air bag 24, thereby expanding the air bag 24, and preventing the air bag 24 from being blown on the screen 11. Sand is piled up on fixed block 8 upper walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com