Ultrahigh-pressure water slip ring

A water slip ring and ultra-high pressure technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of affecting the normal ejection of high-pressure water flow, short service life, and serious wear of water slip rings and other problems, to reduce the possibility, reduce the degree of wear, and ensure the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

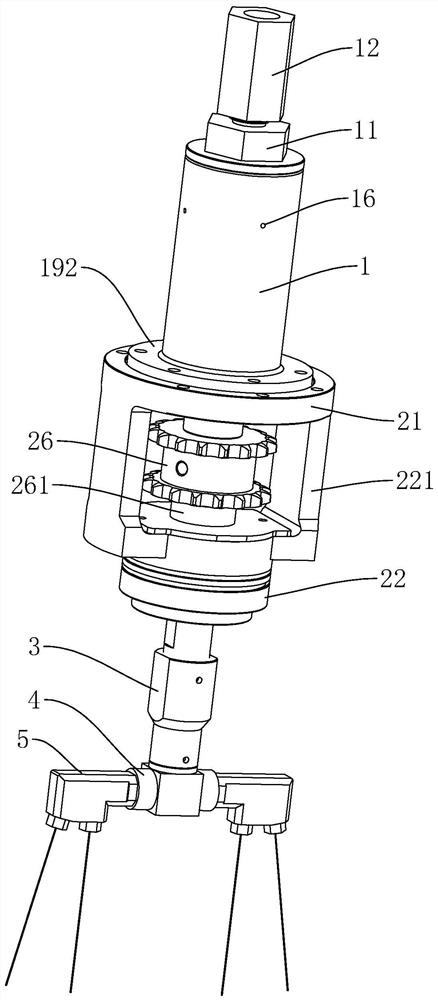

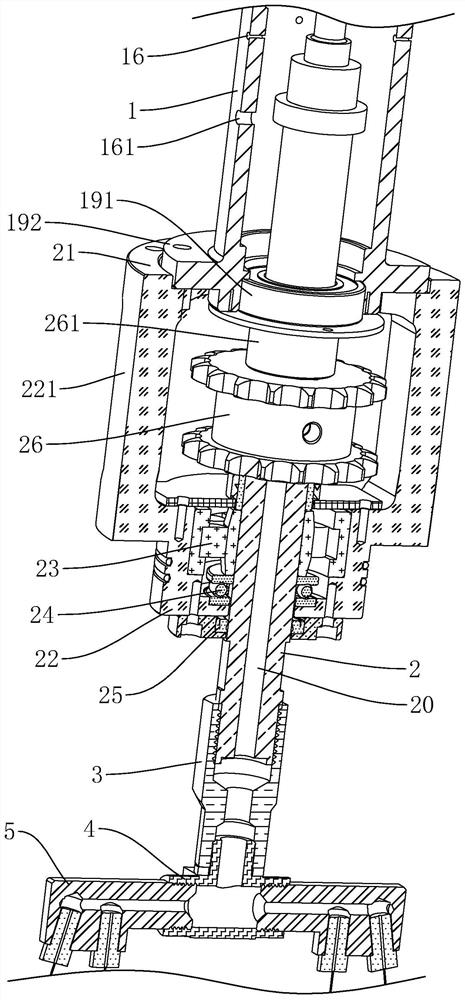

[0038] The following is attached Figure 1-3 The application is described in further detail.

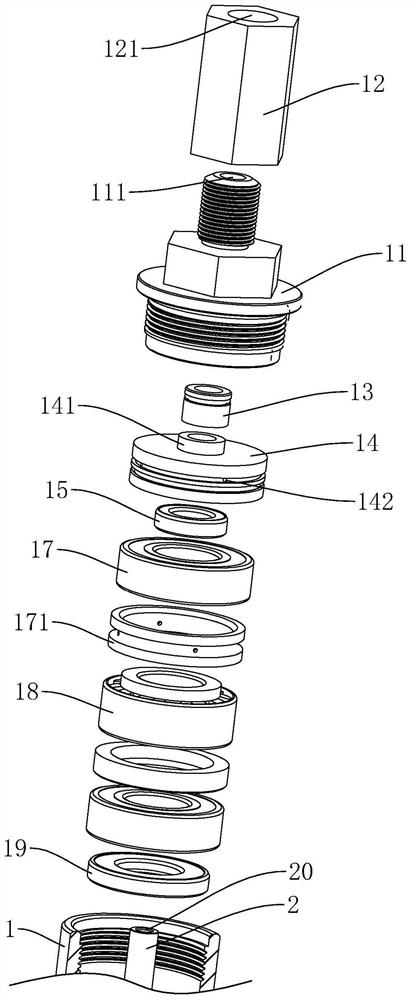

[0039] The embodiment of the present application discloses an ultra-high pressure water slip ring. refer to figure 1 with figure 2 , an ultra-high pressure water slip ring includes a shaft core 2 and a cylindrical shell 1 sleeved outside the shaft core 2, one end of the shell 1 is threaded with a top joint 11, and the top joint 11 is threaded with a water inlet joint 12 .

[0040] refer to figure 2 The shaft core 2 is coaxially provided with a flow channel 20 for water supply and circulation, the top joint 11 is provided with a water inlet 111 connected to the flow channel 20 , and the water inlet joint 12 is provided with a water inlet 121 communicated with the water inlet 111 . One end of the top joint 11 inserted into the housing 1 is covered with a sealing ring close to the opening to achieve the purpose of sealing the top joint 11 and the housing 1 , and to a certain exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com