Automatic press-fitting device for main reduction gear of gearbox

A main deceleration and gearbox technology, applied in the field of automatic press-fitting equipment for the main deceleration gear of the gearbox, can solve the problems of inconvenience, low degree of automation, and inability to be widely used, so as to avoid injury, reduce feeding time, and save manpower. The effect of resource cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Attached below Figure 1-7 The present invention is described in detail below.

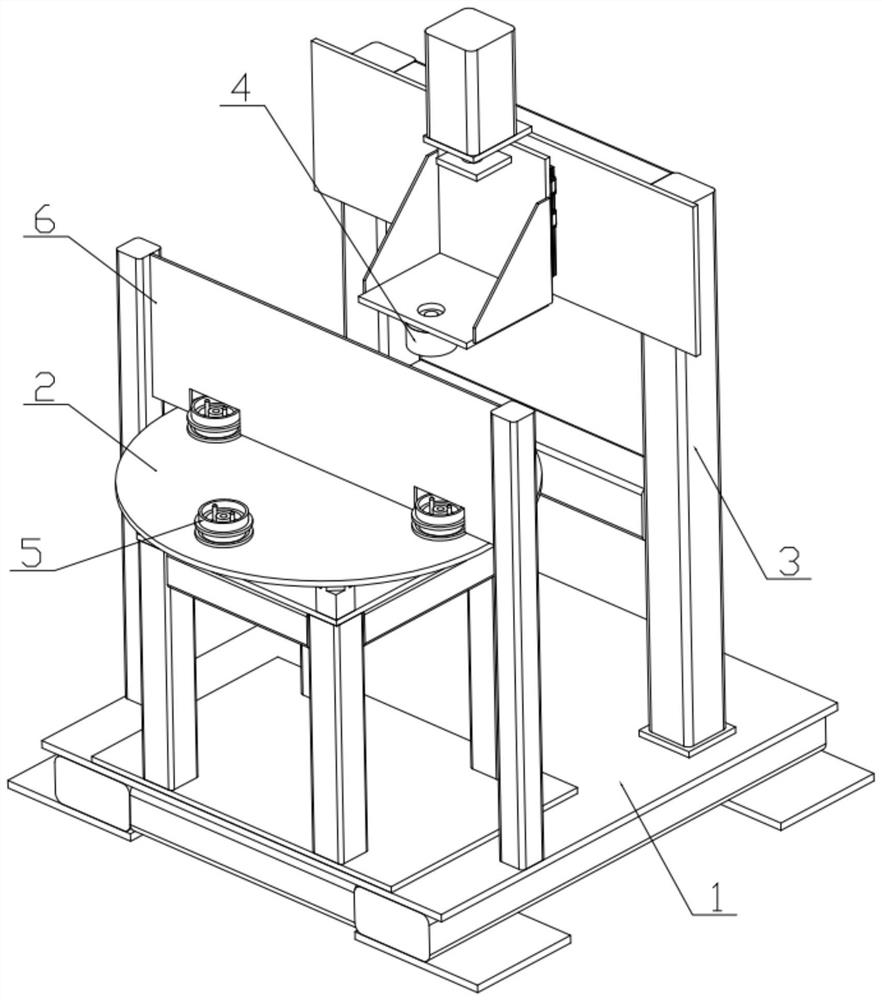

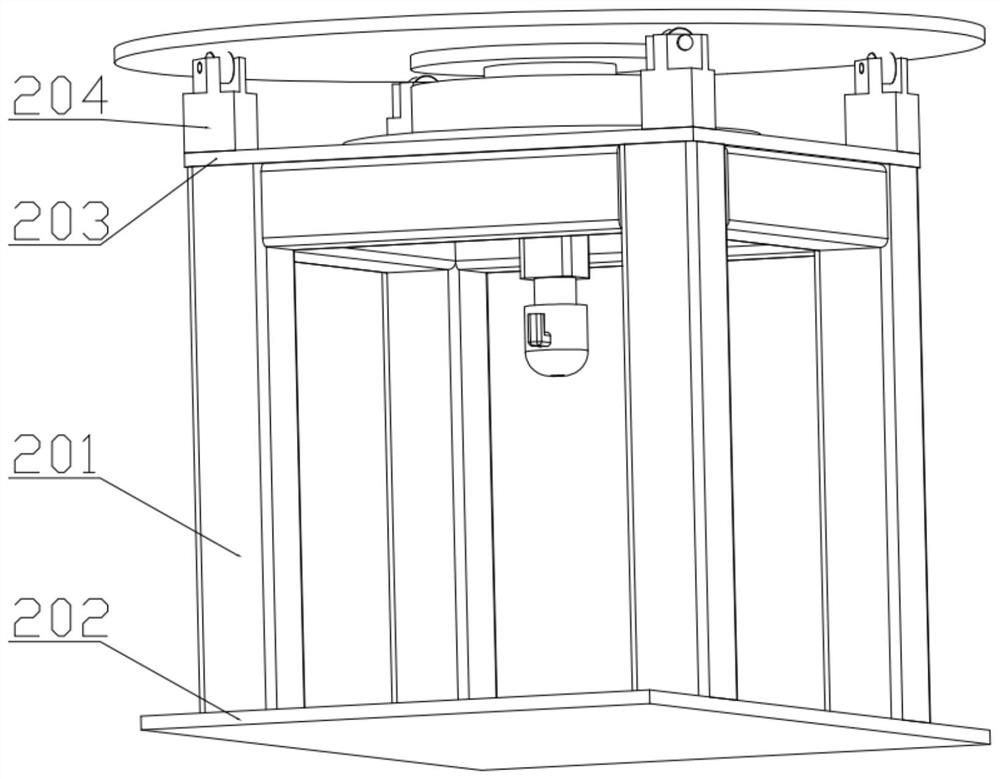

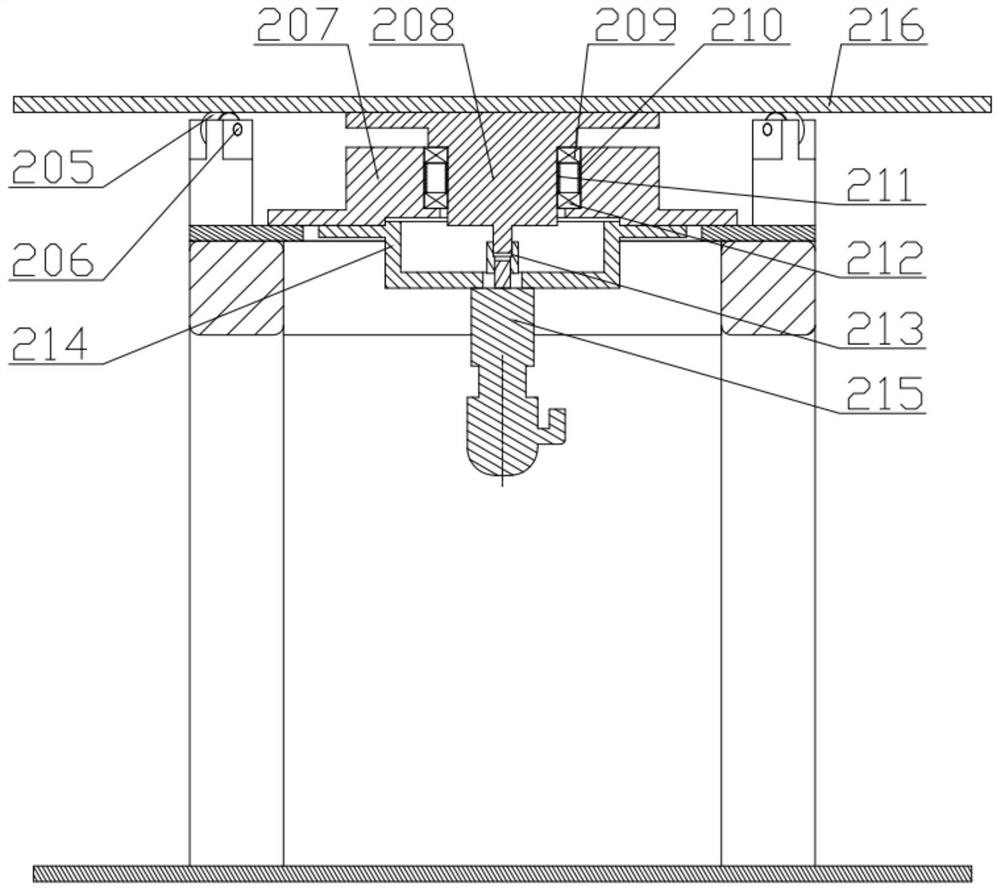

[0028] Such as Figure 1-7 As shown in the figure, there is an automatic press-fitting equipment for the main reduction gear of a gearbox. The surface of the upper plate of the fixed installation base 1 is fixed with a rotary feeding device 2 . The front edge of the rotary feeding device 2 is aligned with the front edge of the fixed installation base 1 , the surface of the upper plate of the fixed installation base 1 and the bottom surface of the lower part of the press-fit column 3 are installed and fixed together, the press-fit column 3 is located at the rear of the fixed installation base 1, the lower plate of the pressure head installation bracket 309 in the press-fit column 3 mechanism The mounting surface is installed together with the upper mounting surface of the pressing head device 4, and there is a round hole in the middle of the lower plate of the pressing head mounting bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com