Electric wrench for engraving machine tool rod

An electric wrench and tool rod technology, applied in the field of wrenches, can solve the problems of difficult operation of the wrench and poor clamping effect of the tool rod, and achieve the effects of avoiding slippage, increasing the clamping force and increasing the frictional resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

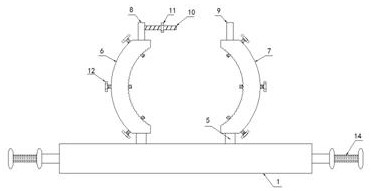

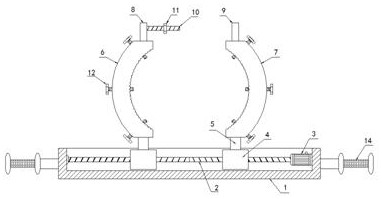

[0024] Embodiment 1, with reference to figure 1 and 2 , an electric wrench for an engraving machine tool bar, comprising a fixed plate 1, the left and right sides of the fixed plate 1 are fixedly provided with handles 14, the upper side of the fixed plate 1 is provided with a bar-shaped groove horizontally, and the inside of the bar-shaped groove A two-way screw rod 2 is arranged horizontally, the left end of the two-way screw rod 2 is rotationally connected with the left side of the bar-shaped groove through a rolling bearing, and a motor 3 is fixed on the right side wall of the bar-shaped groove. The motor 3 adopts a stepping motor, and the model is TB5128FTG , the output end of the motor 3 is fixedly connected to the right end of the two-way screw rod 2 through a coupling, and two moving blocks 4 are arranged for symmetrical sliding inside the strip groove, and the side walls of the two moving blocks 4 pass through the first threaded hole and the The second threaded hole i...

Embodiment 2

[0025] Embodiment 2, with reference to figure 2 , its fastening mechanism includes a first fixed block 8, a second fixed block 9, a one-way screw 10 and a fastening nut 11, the first fixed block 8 is fixedly arranged on the upper end of the first arc splint 6, and the second fixed block The block 9 is fixedly arranged on the upper end of the second arc splint 7, and the one-way screw mandrel 10 is fixedly arranged on the right side wall of the first fixed block 8 in the transverse direction, and the side wall of the second fixed block 9 is provided with a set for the one-way screw mandrel. 10 passes through the mounting hole, and the fastening nut 11 is threaded on the rod wall of the one-way screw rod 10 .

Embodiment 3

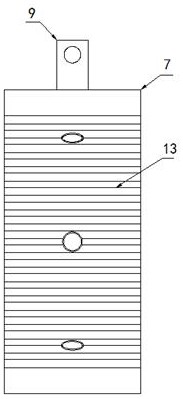

[0026] Embodiment 3, with reference to image 3 , the side walls of its first arc-shaped splint 6 and the second arc-shaped splint 7 are provided with a plurality of evenly distributed third threaded holes, and the internal threads of the third threaded holes are provided with jacking bolts 12, the first arc Both the inner side walls of the curved splint 6 and the second curved splint 7 are provided with anti-slip lines 13 to increase the clamping stability between the first curved splint 6 and the second curved splint 7 and the tool bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com