Fixed-length cutting machine and cutting method of HDPE double-wall corrugated pipe

A double-wall corrugated pipe and cutting machine technology, which is applied in metal processing and other directions, can solve the difficult task of cutting large quantities of fixed-length HDPE double-wall corrugated pipes, unsatisfactory fixing effect of HDPE double-wall corrugated pipes, low work efficiency, etc. problem, to achieve the effect of small error, high degree of automation, and increased weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

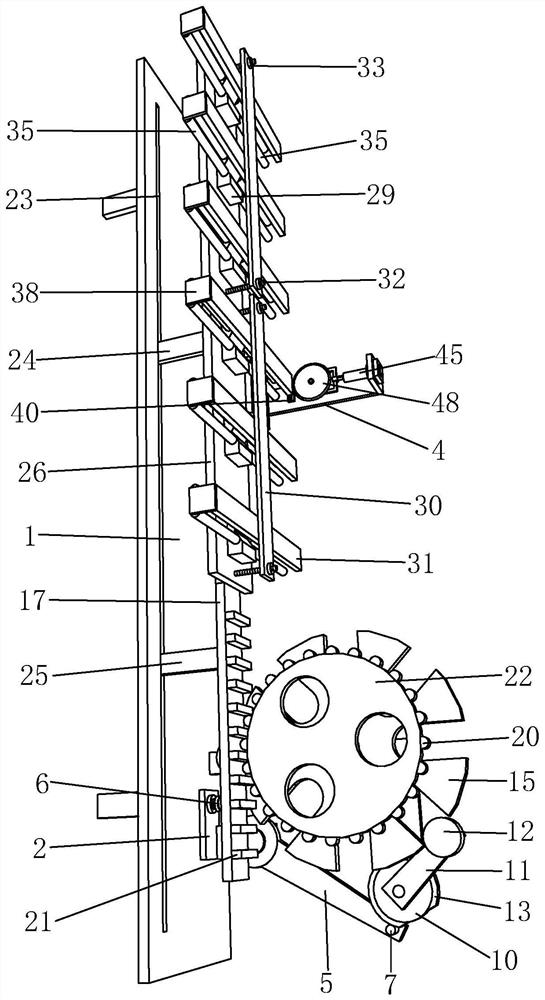

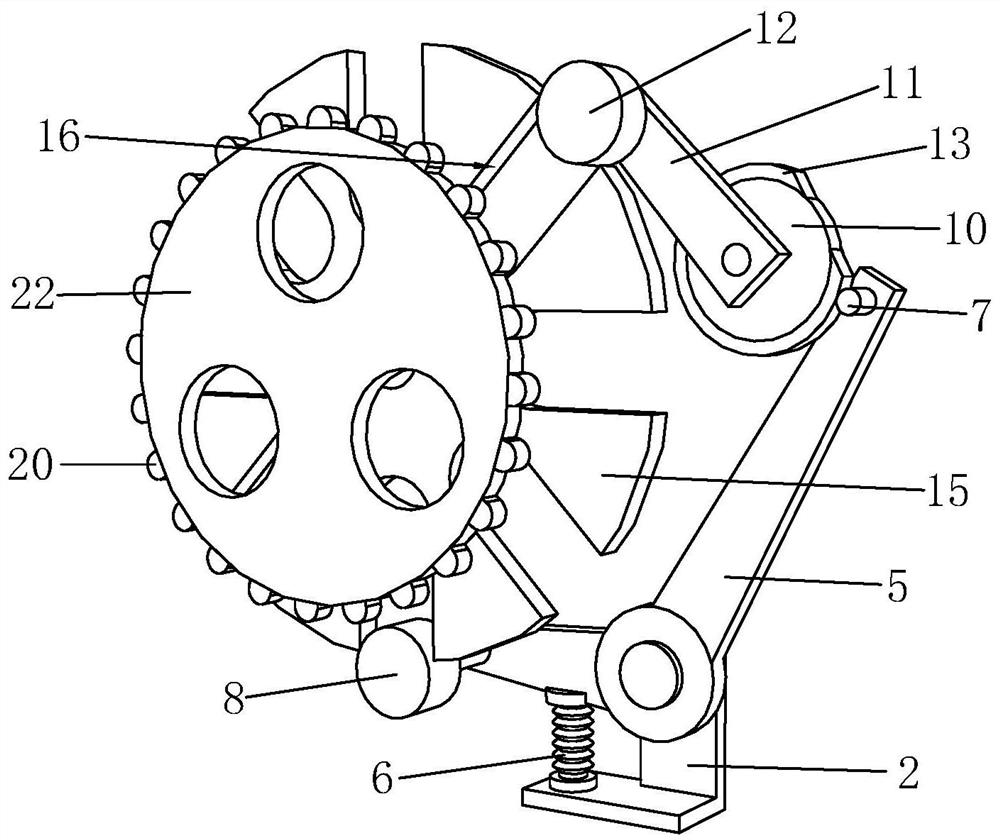

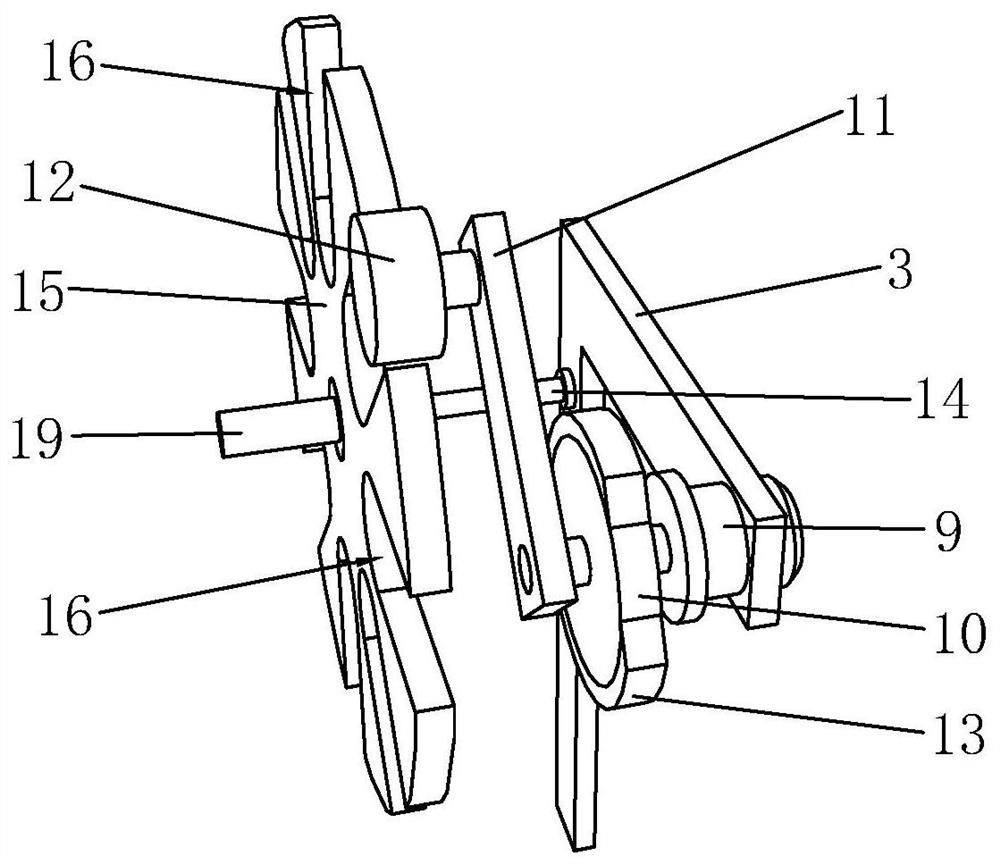

[0040] like Figure 1 to Figure 8 As shown, it is a fixed-length cutting machine for HDPE double-wall corrugated pipe of the present invention, including a workbench 1 and a cutting mechanism. The workbench 1 is provided with a first support 2, a second support 3 and a third support 4, and the first support 2 is rotatably connected with a V-shaped swing link 5, and a spring bar 6 is arranged between the V-shaped swing link 5 and the first support 2, so that the V-shaped swing link 5 and the first support 2 are pinned and connected together, and the V-shaped swing link is limited. The rotation range of the rod 5, the two ends of the V-shaped swing rod 5 are respectively provided with a fixed pin 7 and a positioning pin 8, the fixed pin 7 is located above the positioning pin 8, the second support 3 is provided with a drive motor 9, and the drive motor 9 The motor shaft is respectively provided with a driving disc 10 and a mounting rod 11, the mounting rod 11 is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com