Embedded control system and method for vertical radial extrusion pipe making equipment

An embedded control and control system technology, applied in auxiliary molding equipment, manufacturing tools, ceramic molding machines, etc., can solve the problems of function and cost waste, high PLC cost, etc., to improve production efficiency, improve production quality, and improve control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

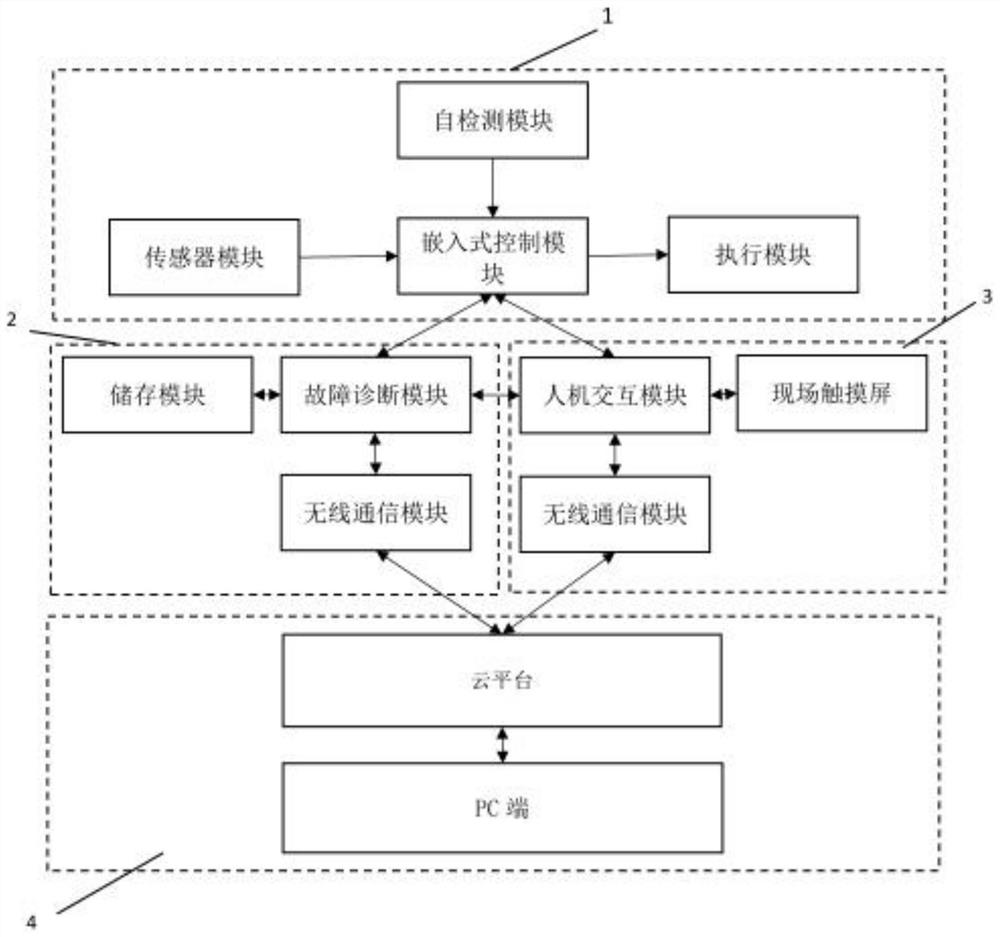

[0038] Such as figure 1 , shows an overall structural block diagram of an automated production control system in an embodiment of the present invention, a control method for vertical radial extrusion pipe-making equipment with embedded technology, including a main control subsystem 1, a fault detection subsystem 2, a man-machine Interactive subsystem 3 and data storage terminal 4.

[0039] The main control subsystem 1 includes a self-detection module, an embedded control module, a sensor module, and an execution module. The sensor module mainly performs real-time positioning detection, equipment operation parameter collection and system safety parameter collection for the control execution equipment in the pipe making process. and other functions; the embedded control module completes the motor control, hydraulic control and production process of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com