Automatic strap folding machine for plastic handbag

A handbag and belt folding machine technology, which is applied in bag making operations, paper/cardboard containers, containers, etc., to achieve the effect of high flexibility and accurate installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

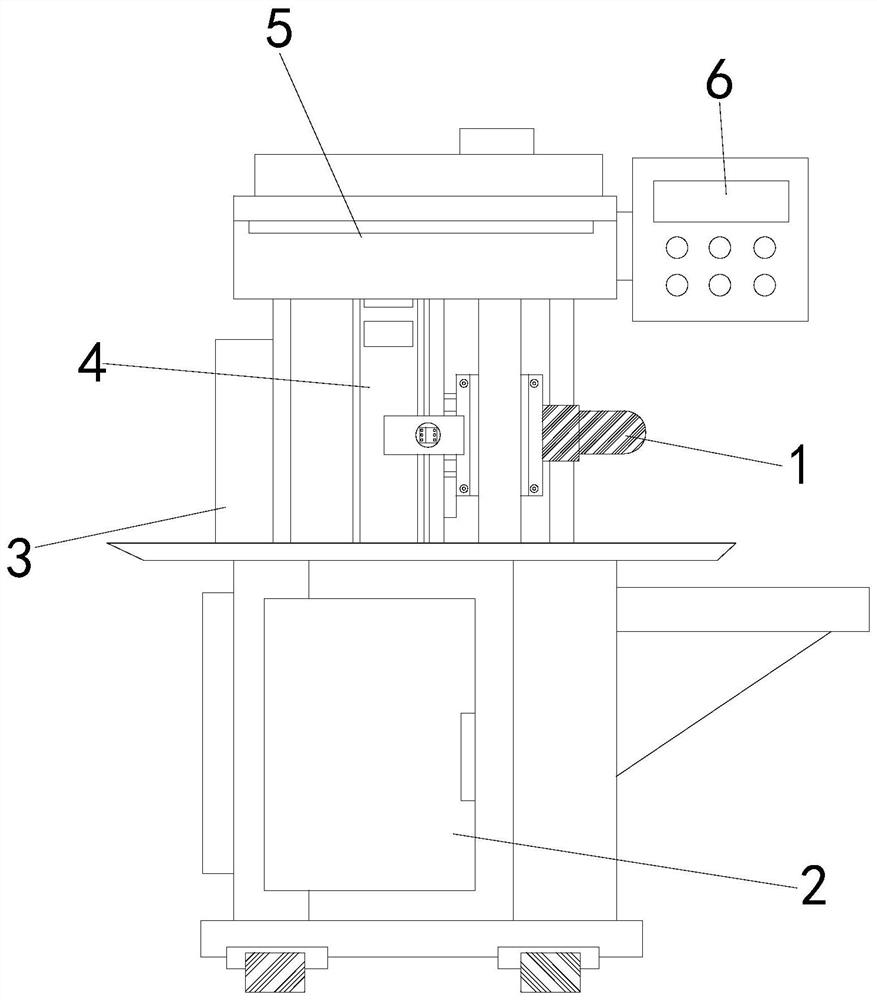

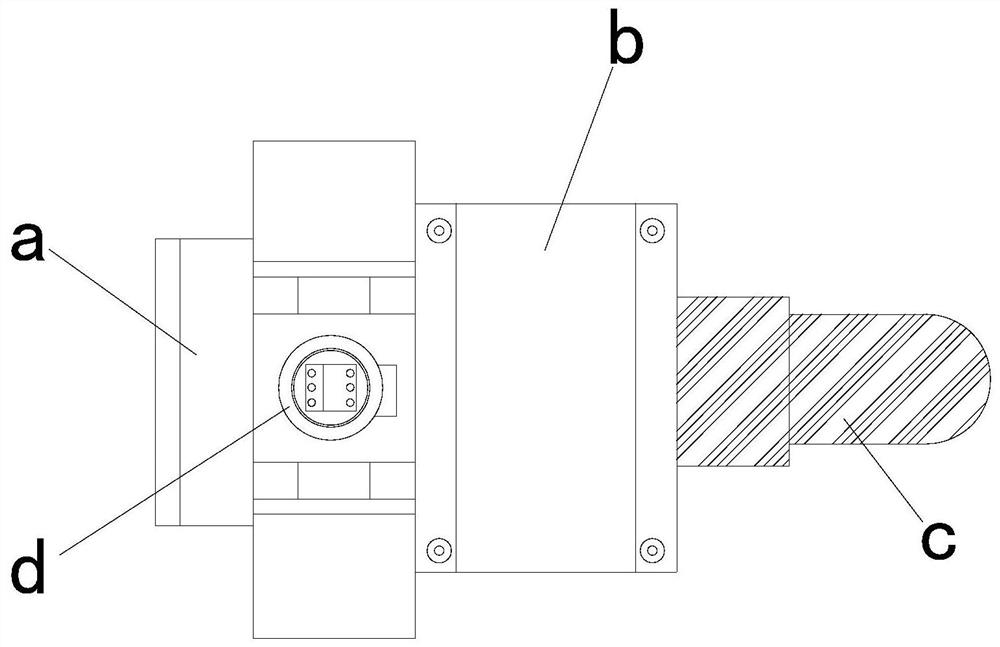

[0025] see Figure 1-Figure 2 , the present invention provides a technical solution for an automatic folding machine for plastic handbags: its structure includes: a sealing frame body 1, a processing table 2, a rear baffle 3, a fixing frame 4, a power distribution device 5, and a controller 6. The controller 6 is installed on the right side of the power distribution device 5 and is electrically connected with the power distribution device 5. A fixed frame 4 is arranged below the power distribution device 5, and the fixed frame 4 is locked with the power distribution device 5. The fixed frame 4. The inside of the tape holder body 1 is provided, and the tape holder body 1 is locked with the fixed frame 4. The rear side of the tape holder body 1 is provided with a rear baffle 3. The tape holder body 1 includes a positioning frame Device a, limit frame b, indicator rod c, servo motor unit d, the indicator rod c is installed on the outside of the limit frame b and locked with the l...

no. 2 example

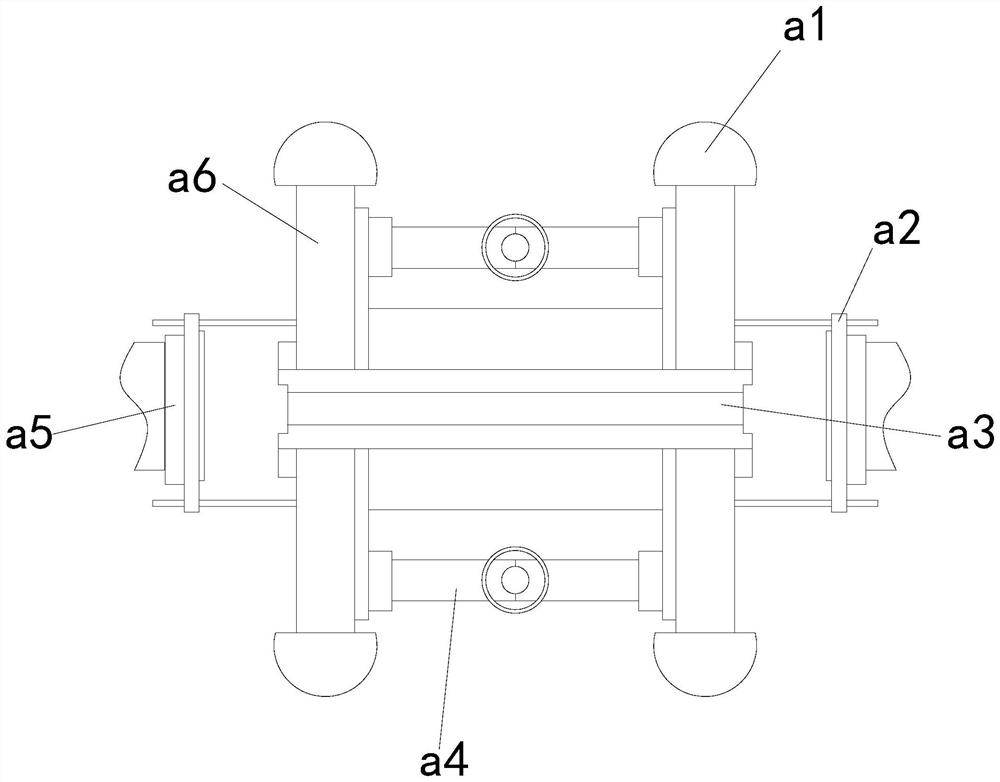

[0028] see Figure 3-Figure 5 , the present invention provides a technical solution for an automatic folding machine for plastic handbags: its structure includes: the positioning frame device a includes a strut device a1, a movable frame a2, a belt slot a3, an adjusting frame a4, a heat sealing plate a5, Assembling cylinder a6, the heat sealing plate a5 runs through the inner side of the movable frame a2, the inner side of the movable frame a2 is provided with an assembly cylinder a6, the middle side of the assembly cylinder a6 is provided with an adjustment frame a4, and the adjustment frame a4 is connected with the assembly cylinder a6 is movably connected, and the four directions of the assembly cylinder a6 are provided with a strut device a1, and the strut device a1 is in clearance fit with the assembly cylinder a6, and the belt slot a3 is socketed on the side of the assembly cylinder a6.

[0029] The strut device a1 includes a ball sleeve a11, a support ball a12, and a te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com