Manufacturing process of leaf vein picture

A technique of making crafts, leaf veins, applied in the field of leaf vein painting, to achieve the effect of avoiding corrosion or uneven bleaching, corrosion or uniform bleaching of leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of manufacturing process of leaf vein painting is characterized in that: comprises the following steps:

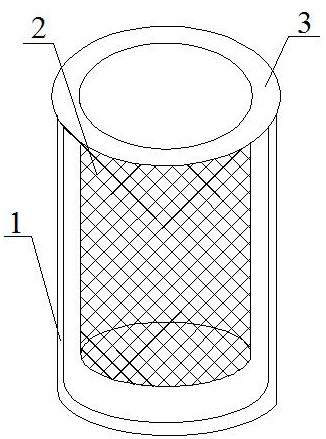

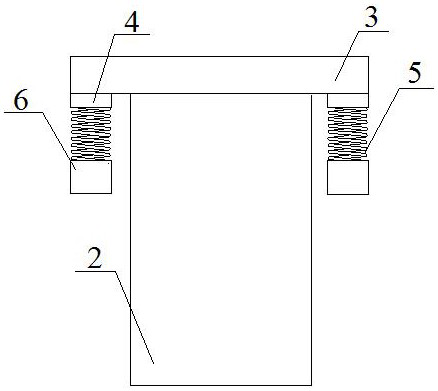

[0041] Step 1. Corrosion

[0042] Select the leaves, the selected leaves are magnolia leaves, Photinia red leaves and sweet-scented osmanthus leaves, you can also select thick leaves with well-developed veins, and place the selected leaves in the container 1 containing the corrosive solution for corrosion. Container 1 is provided with a placement mechanism, and the position of the selected leaves in the container is as follows: the selected leaves are located in the inner cavity of the placement mechanism, and then the container is placed on the electric stove, and heated and boiled until the leaves become soft and the solution becomes deep. Color, obtain the corroded leaf vein; Corrosion solution is the mixed solution that utilizes the sodium hydroxide solution of 50g / L of balance weighing configuration and the sodium carbonate solution of 70g / L, and the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com