A built-in adjustable position suspension handle device for buses

A bus, built-in technology, applied to the special position of the vehicle, vehicle components, transportation and packaging, etc., can solve the problems of not being able to stand firmly, discomfort when touching the body, danger, etc., and achieve a practical, comfortable and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

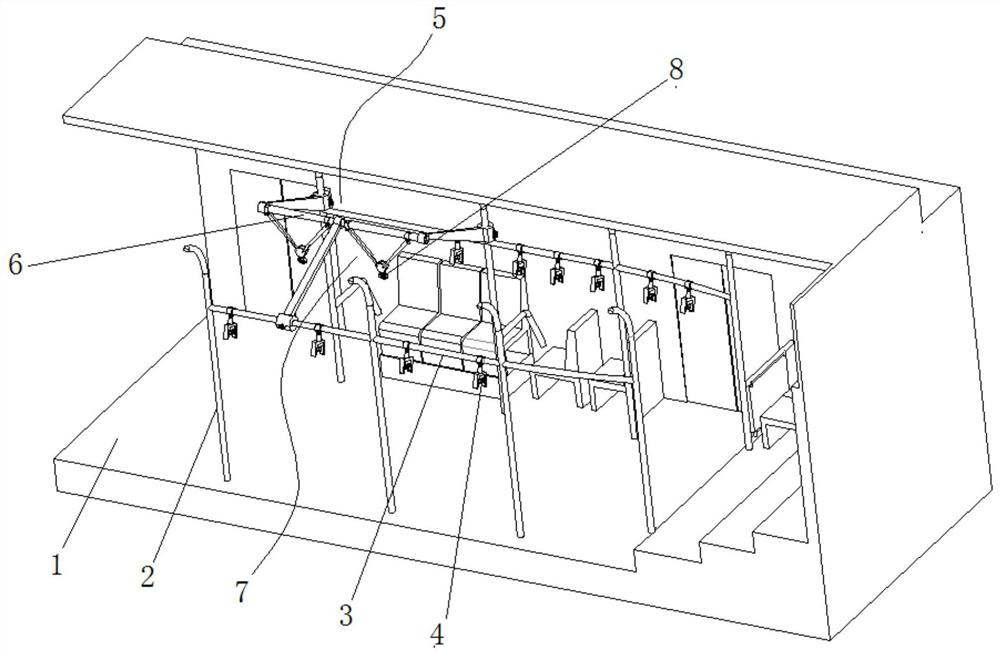

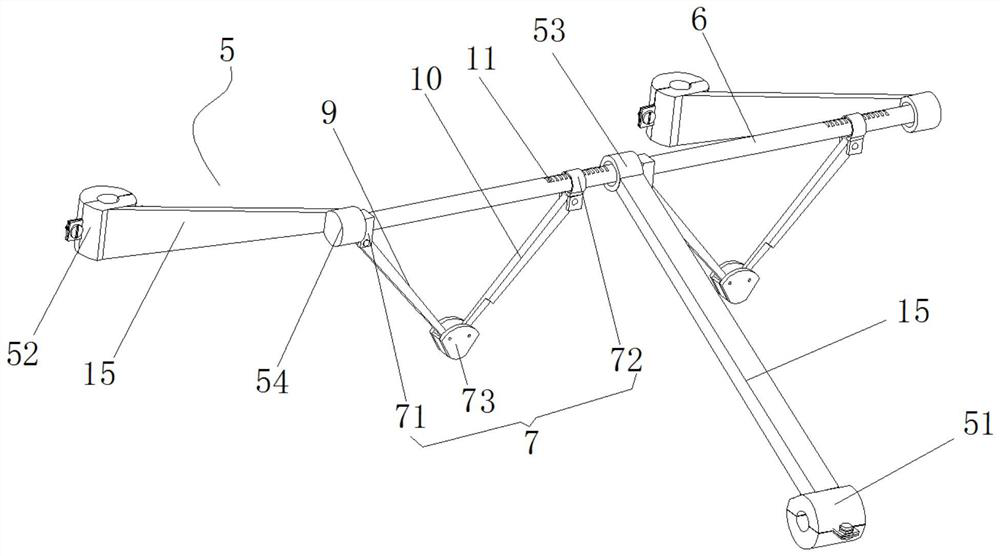

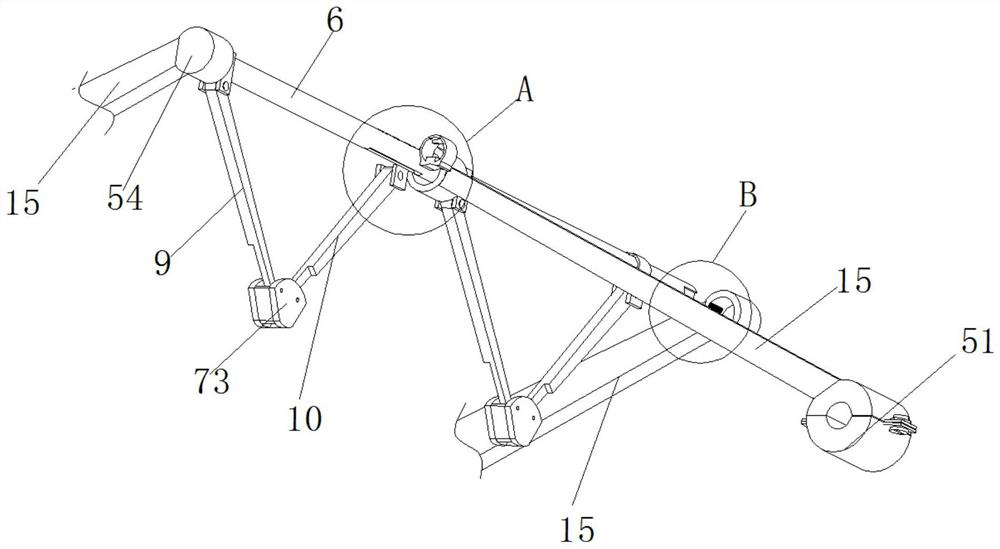

[0028] Embodiment one, such as Figure 1-7 Shown: a bus built-in adjustable suspension handle device, including a bus body 1, the two sides of the car body 1 are respectively provided with a plurality of uprights 2 at intervals, between two adjacent uprights 2 The upper side of the upper side is respectively connected by the support rod one 3, and the support rod one 3 is provided with a fixed pull handle 4 at intervals, and the corresponding vertical rod 2 and the support rod one 3 on both sides are respectively movably connected with a support member 5, and the inner side of the support member 5 And be positioned at the middle part of car body 1 and be fixedly provided with support bar two 6, support bar two 6 height is higher than support bar one 3 in vertical direction, and support bar two 6 is provided with a plurality of adjustment parts 7, and adjustment part 7 is provided with Active pull handle 8 is arranged.

[0029] as attached Figure 1-2 As shown, a suspension h...

Embodiment 2

[0044] Embodiment two, such as Figure 8-9 Shown: the structure of the connection between the connecting seat 73 and the movable pull handle 8 is different from that of Embodiment 1, and the rest of the structures are the same.

[0045] The inside of connecting seat 73 is hollow, and the lower side is open, and the inner side wall of connecting seat 73 is pivotally connected with running wheel 27 by rotating shaft 26, and a wide rope 21 is wound on the running wheel 27, and the outer side end of wide rope 21 and movable pull handle 8 Link to each other, another wide rope 21 is also connected between the bottom of the connection seat 73 and the movable pull handle 8 (need to have a certain surplus, to coordinate the adjustment of another wide rope 21 degree is applicable).

[0046] A through hole 28 is provided on the connecting seat 73, and the size of the through hole 28 matches the size of the rotating shaft 26. The outer end of the rotating shaft 26 is connected with a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com