Drum washing machine and control method thereof

A technology for drum washing machines and washing programs, which is applied to the control device of washing machines, other washing machines, washing machines with containers, etc., which can solve the problems of affecting the sealing effect of the door seal, increasing the burden on the motor, and being difficult to implement, so as to improve the health and the user Experience, avoid dirt adhesion, and save water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

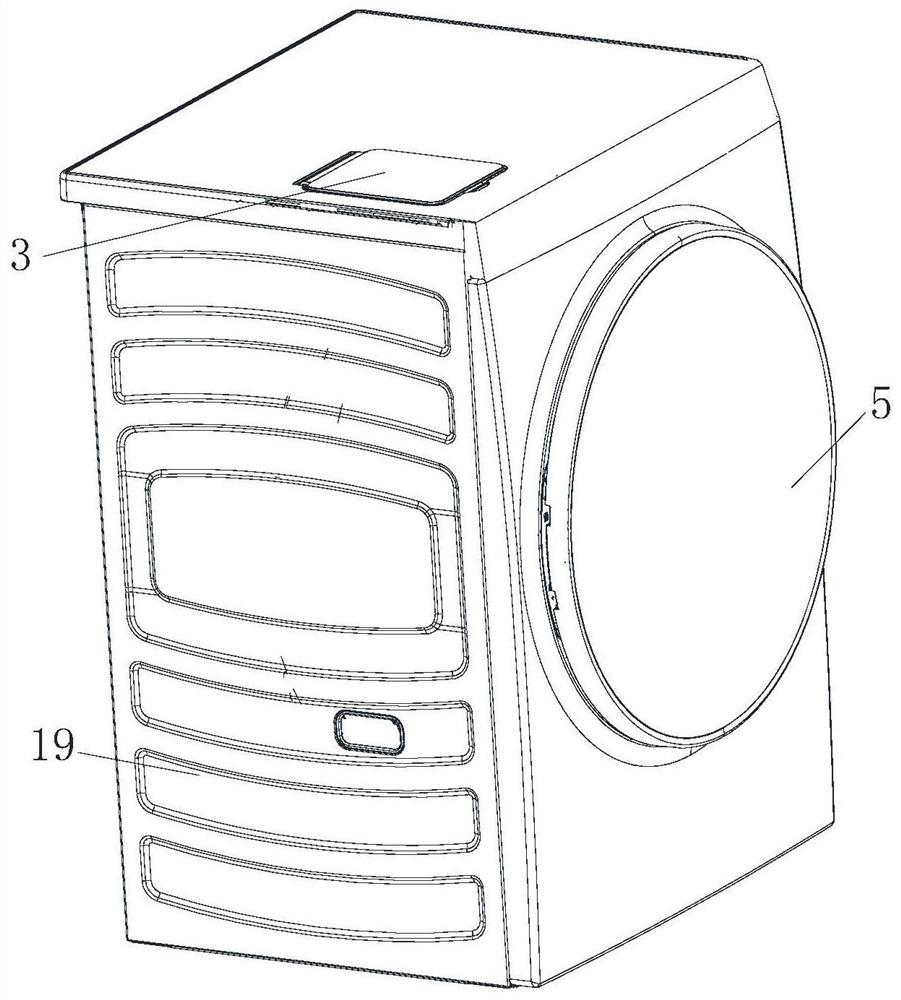

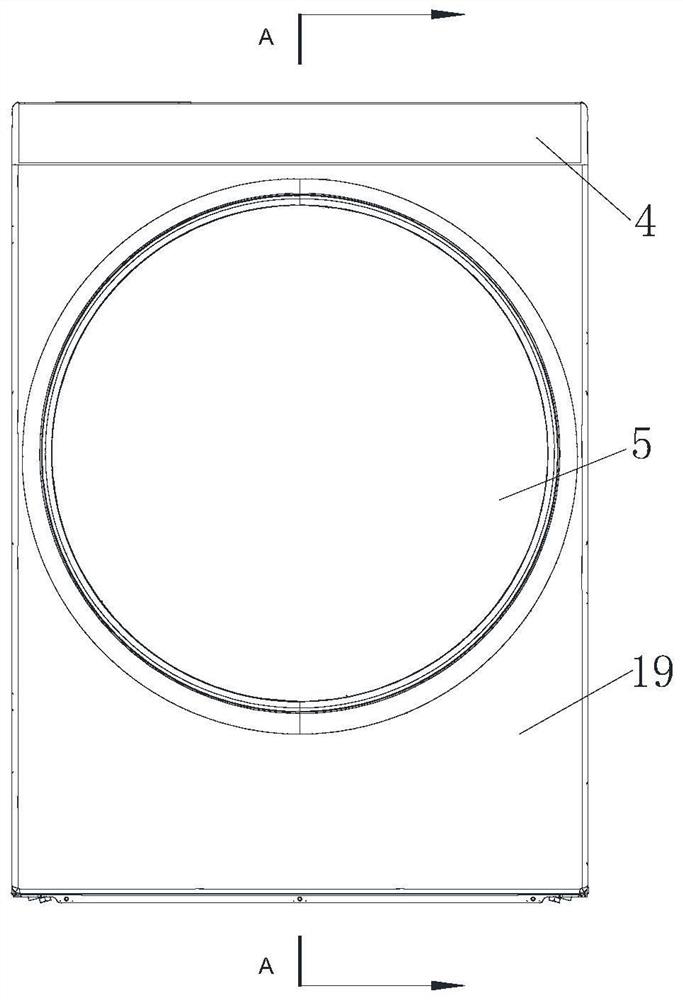

[0069] Such as Figure 1-5 Shown, a kind of drum washing machine of the present embodiment comprises:

[0070] Inner cylinder 17;

[0071] The inner cylinder door 6 is installed on the mouth of the inner cylinder 17 which can be opened / closed;

[0072] The inner cylinder 17 and the inner cylinder door 6 jointly form an independent washing chamber, which holds washing water independently when washing clothes.

[0073] The drum washing machine of this embodiment installs the inner cylinder door 6 on the mouth of the inner cylinder 17, and the inner cylinder 17 adopts a non-porous cylinder design, and the two together form an independent washing chamber. Filling the washing / rinsing water between the inner cylinder and the outer cylinder greatly reduces the washing water consumption of the washing machine; avoids the possibility of dirt adhesion between the inner cylinder and the outer cylinder; greatly improves user health and user experience, and greatly Greatly saves water r...

Embodiment 2

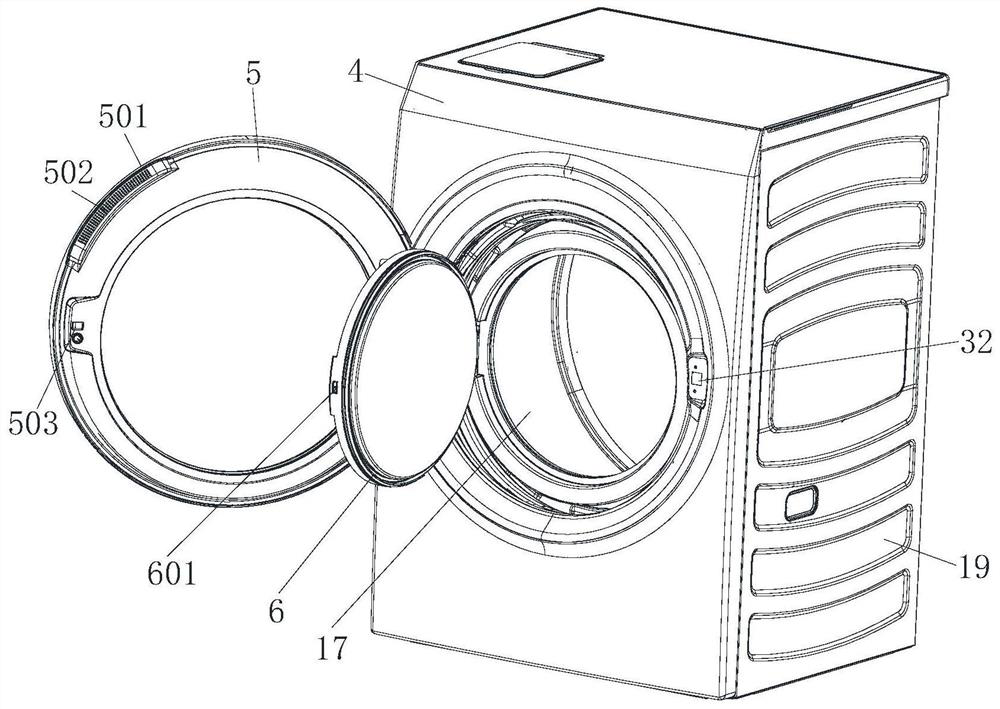

[0084] Such as Figure 1-9 Shown, a kind of drum washing machine of the present embodiment comprises:

[0085] Inner barrel 17;

[0086] The inner cylinder door 6 is installed on the mouth of the inner cylinder 17 which can be opened / closed;

[0087] A sealing device is arranged between the cylinder mouth of the inner cylinder 17 and the inner cylinder door 6, and the cylinder mouth of the inner cylinder 17 is kept sealed and closed by the sealing device when the inner cylinder door 6 is closed, and the inner cylinder 17 and the inner cylinder door 6 jointly form an independent washing chamber , Independently hold the washing water when washing clothes.

[0088] The drum washing machine of this embodiment realizes that when the inner cylinder door 6 is closed, the cylinder mouth of the inner cylinder 17 is sealed and closed through the sealing device, so that the washing water is only in the inner cylinder during washing or rinsing, so as to avoid the water leakage of the in...

Embodiment 3

[0102] Such as Figure 1-5 , Figure 10-15 Shown, a kind of drum washing machine of the present embodiment comprises:

[0103] Inner barrel 17;

[0104] The inner cylinder door 6 includes a fixedly connected door outer cover and a door inner cover 602;

[0105] The inner cylinder door 6 can be opened / closed and installed on the mouth of the inner cylinder 17. When closed, the inner cylinder 17 and the inner cylinder door 6 together form an independent washing chamber, and the washing water is independently contained when washing clothes. .

[0106] Such as Figure 10 , 11 As shown, specifically, the door outer cover includes a base cover 603 and a decorative cover 604, the door inner cover 602 is installed on one side of the base cover 603, and the decorative cover 604 is installed on the other side of the base cover 603 side.

[0107] Preferably, the door inner cover 602 is fixedly connected to the base cover 603 through screws 42 .

[0108] The decorative cover 604 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com