Double-drum washing machine

A washing machine and double-drum technology, applied in the field of washing machines, can solve problems such as safety, hidden dangers, and high noise, and achieve the effects of being suitable for popularization and use, simple in structure, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the drive suspension assembly 10 of the double-drum washing machine needs to meet at least one of the following trim conditions after being balanced by the counterweight structure 5, and the specific trim conditions are as follows:

[0040] first trim condition

[0041] In the vertical up and down direction, the center of gravity of the suspension assembly 10 after the counterweight structure 5 is set is lower than the rotation axis of the first washing unit 1 and higher than the rotation axis of the second washing unit 2, and the center of gravity of the assembly is located in the first washing unit 1 and the second washing unit 2 form the middle position of the suspension assembly 10 to ensure the smooth operation of the whole machine. The above-mentioned rotation axis of the first washing unit 1 is the axis of the first inner tub 102 , and the rotation axis of the second washing unit 2 is the axis of the second inner tub 202 .

[0042] Preferably...

Embodiment 2

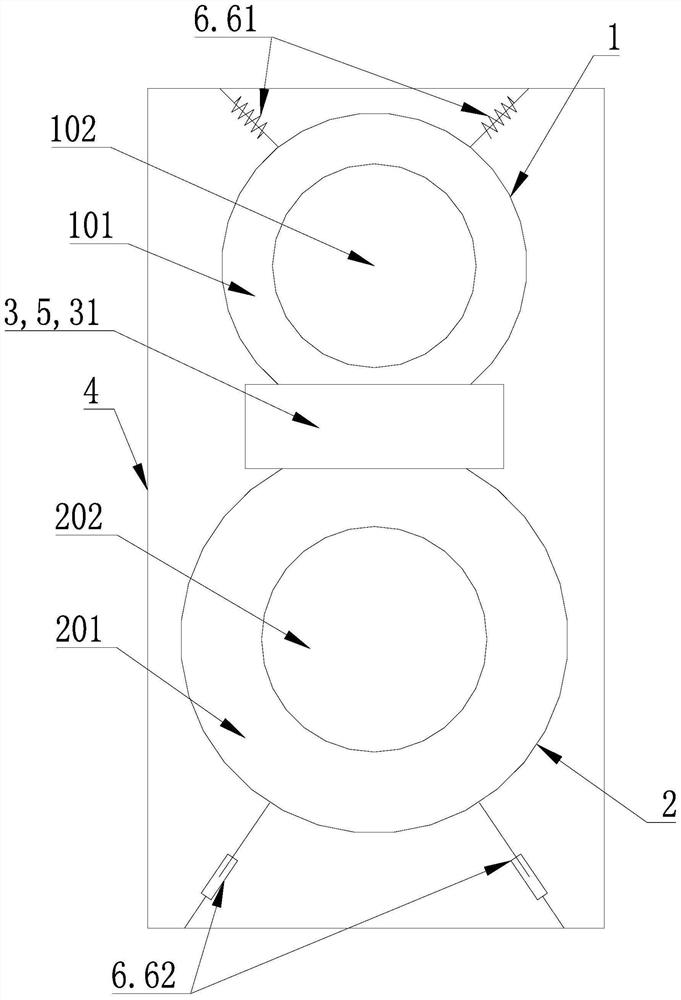

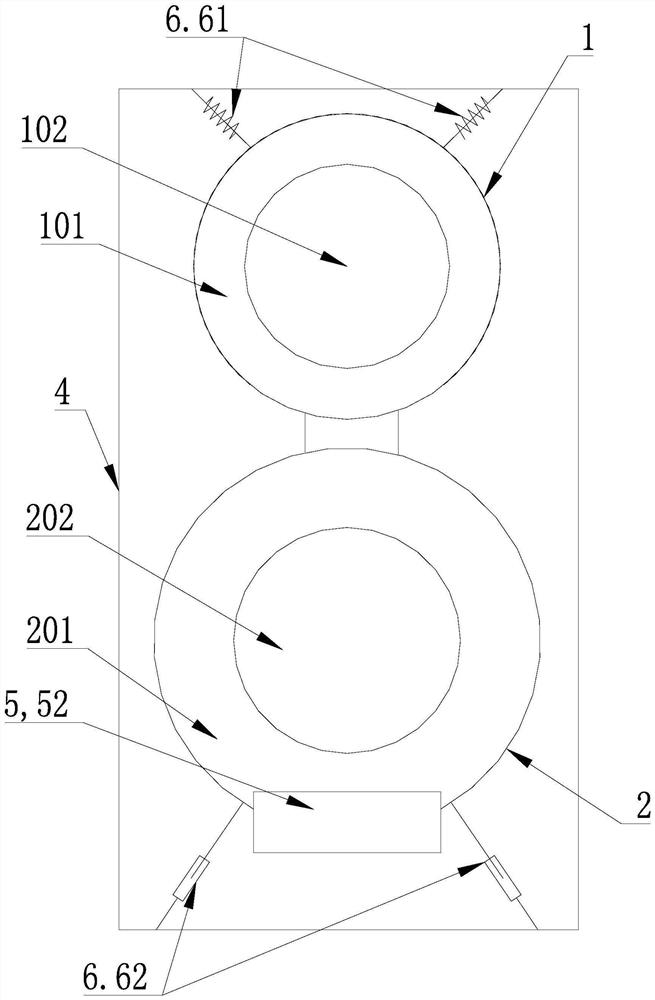

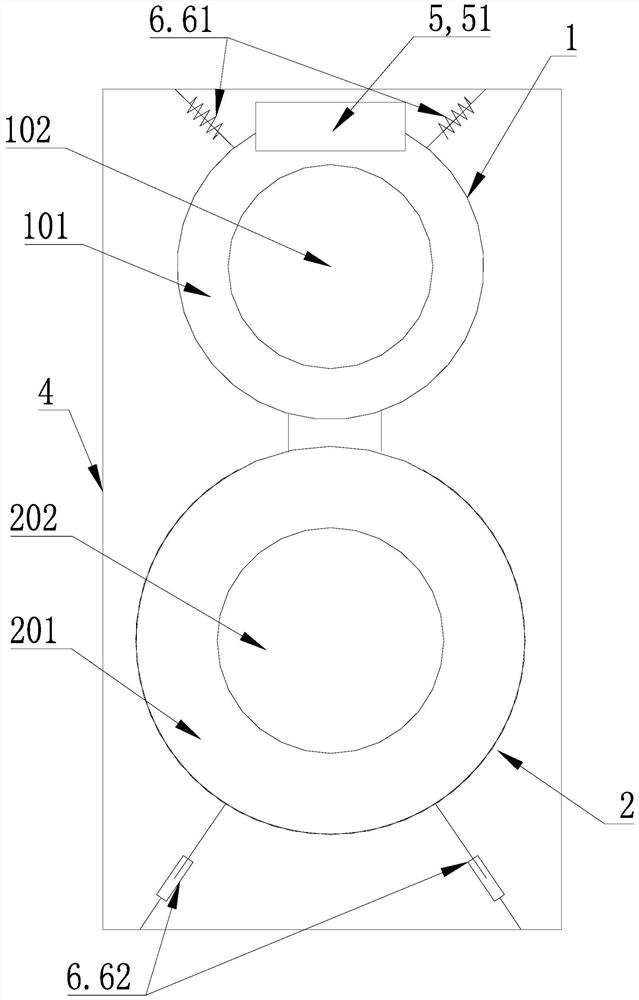

[0062] Such as Figure 1 to Figure 6 As shown, a double-drum washing machine is introduced in this embodiment, which includes a first washing unit 1 and a second washing unit 2 connected as a whole to form a suspension assembly 10, the suspension assembly 10 is connected with at least one shock absorber One end of the components 6 is connected, and the other end of each shock absorbing component 6 is connected with the shell 4 , so that the suspension assembly 10 is hoisted in the shell 4 . The resultant force of the external force exerted by each shock absorber 6 on the suspension assembly 10 is the elastic hoisting force, and the intersection point of the plane where the direction of the elastic hoisting force is co-located with the rotation axis of the first washing unit 1 and the rotation axis of the second washing unit 2 is the elastic center. The weight of the counterweight structure 5 is greater than the sum of the weights of the first motor 103 and the second motor 203...

Embodiment 3

[0074] Such as Figure 1 to Figure 6 As shown, a double-drum washing machine is introduced in this embodiment, which includes a first washing unit 1 and a second washing unit 2 that are connected as one and constitute a suspension assembly 10. The weight of the first washing unit 1 does not exceed the weight of the second washing unit. Weight of washing unit 2. By setting the weight of the second washing unit 2 at the lower part greater than the weight of the first washing unit 1 at the upper part, the center of gravity of the two connected washing units is set lower, so as to reduce the height of the center of gravity of the suspension assembly 10, thereby reducing the double drum The effect of the vibration noise of the washing machine. At the same time, during the operation of the double-drum washing machine, since the two washing units are connected, the two can provide the function of shock-absorbing counterweight to each other, and because the center of gravity of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com