Positioning device for concrete corner structure pouring and using method of positioning device

A technology for pouring concrete and positioning device, which is applied in the preparation of building components on site, building construction, and processing of building materials, etc. Avoid section size deviation, improve installation and construction quality, and ensure the effect of hole forming size and use function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

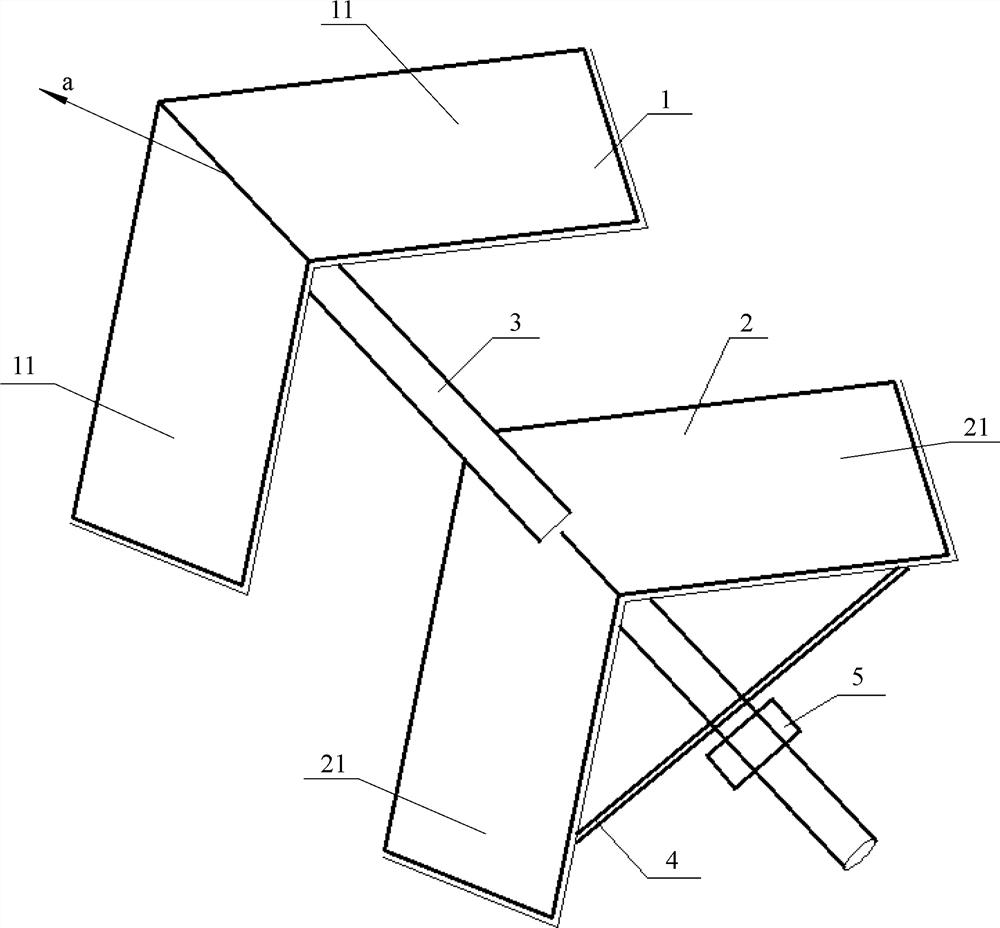

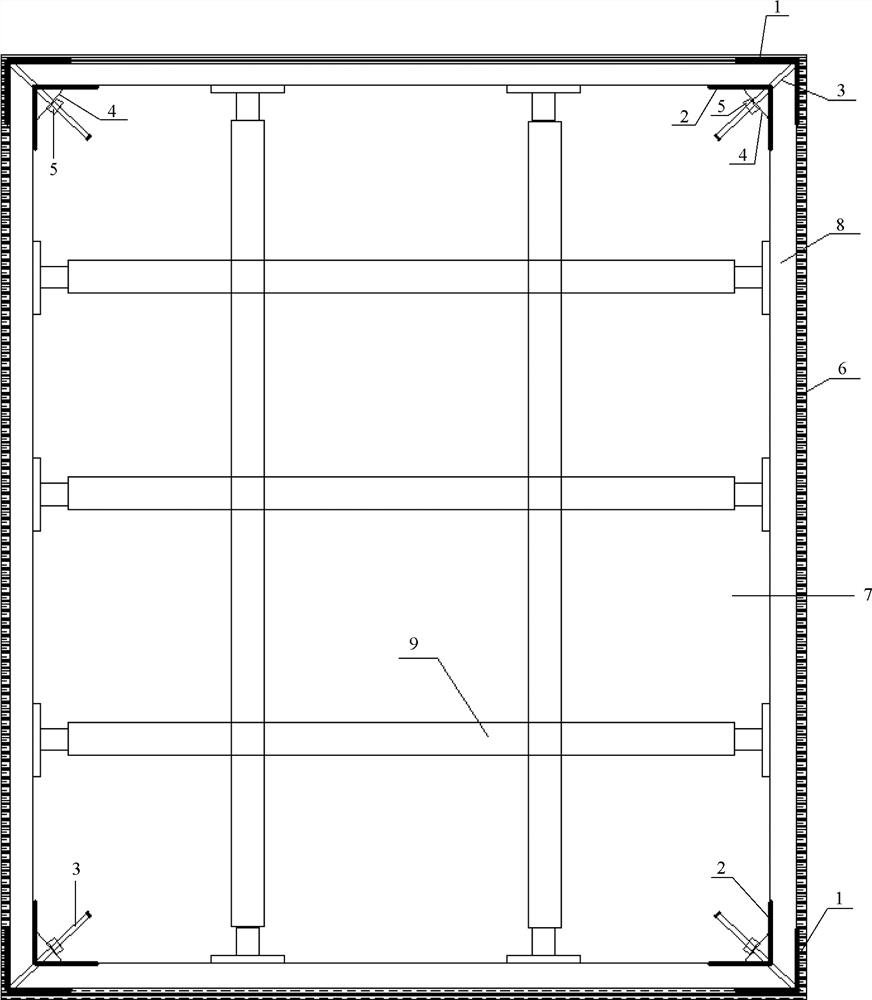

[0025] A positioning device for pouring concrete corner structures, including an end hoop 1, an inner hoop 2, a tie rod 3, a limiting plate 4 and a fastening nut 5, such as figure 1 As shown, the specific structure is:

[0026] The end hoop 1 is composed of two mutually perpendicular end fixing plates 11, each of which uses one side as the end common side to fit and fix each other, and the inner hoop 2 is composed of two mutually perpendicular inner fixing plates 21, each of which uses one side as the inner common side Fitted and fixed to each other, an inner through hole is provided at the midpoint of the inner common side of the inner hoop 2;

[0027] The outer end of the tie rod 3 is fixed at the midpoint of the common side of the concave side of the end hoop 1, and the inner end of the tie rod 3 passes through the inner through hole of the inner hoop 2 so that the inner hoop 2 is movably strung on the tie rod 3. the convex side of ferrule 2 towards the concave side of end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com