Fixing device and construction method for pre-embedded parts of anti-collision guardrail

A technology of anti-collision guardrails and fixing devices, which can be applied to road safety devices, bridge parts, roads, etc. It can solve the problems that the installation quality of embedded parts cannot meet the construction requirements and the hidden dangers of guardrail installation, so as to improve the quality of installation and construction, and the construction is fast , Improve the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it is not intended as a limitation of the present invention.

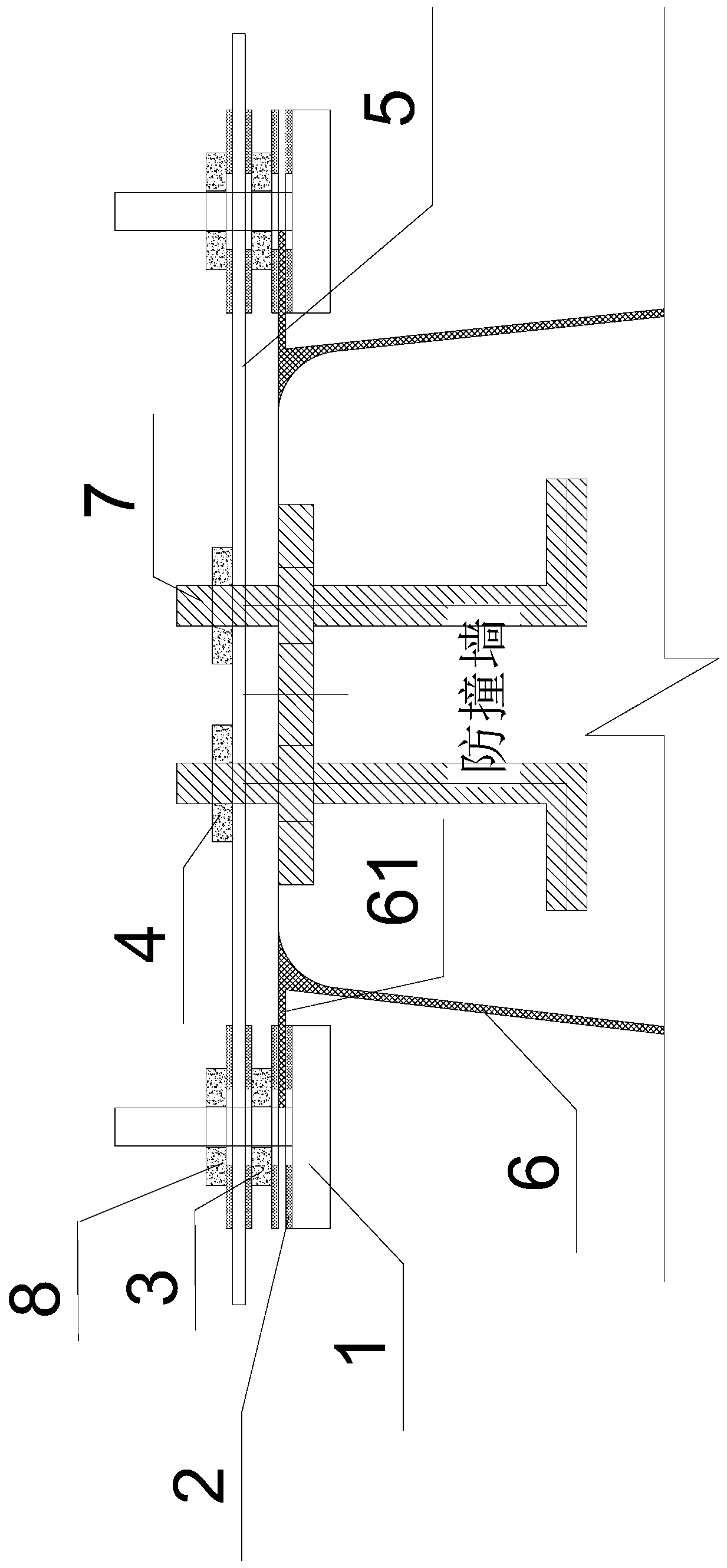

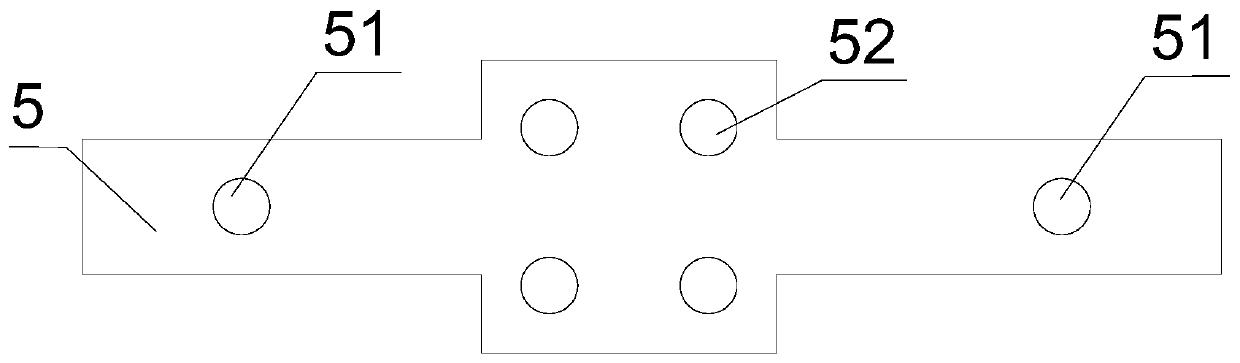

[0029] Such as Figure 1~5 As shown, the present invention discloses a fixing device for the embedded part of the anti-collision barrier. The fixing device is applied on the formwork 6 of the anti-collision barrier to fix the embedded part 7. A plurality of pre-embedded screws on the pre-embedded steel plate; yes, the fixing device includes a positioning bolt 1, a first nut 4, a second nut 3, a third nut 8 and a positioning steel plate 5, and the first nut 4 and the pre-embedded The screw rods are matched, and the second nut 3 and the third nut 8 are all matched with the positioning bolt 1 (the second nut 3 and the third nut 8 can be the same nut); the two sides of the above-mentioned positioning steel plate 5 are all provided with positioning holes 52 The middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com