Large-section steel box girder and construction method thereof

A construction method and technology of steel box girders, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult hoisting and low efficiency of hoisting and assembling steel box girders, and improve construction quality and coating Construction efficiency and safety, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

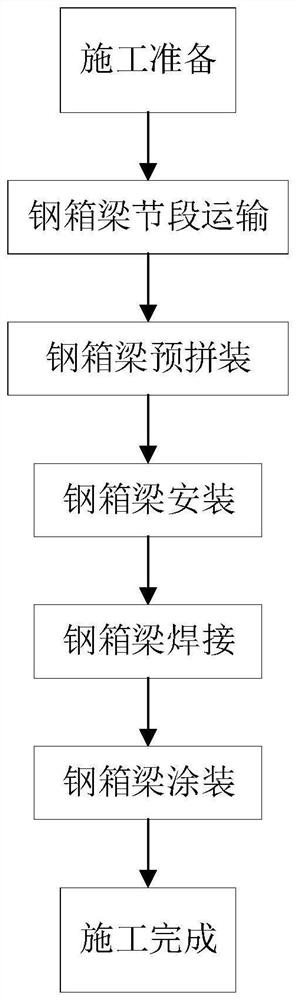

[0040] Such as figure 1 As shown, the large-section steel box girder construction method includes the following construction steps:

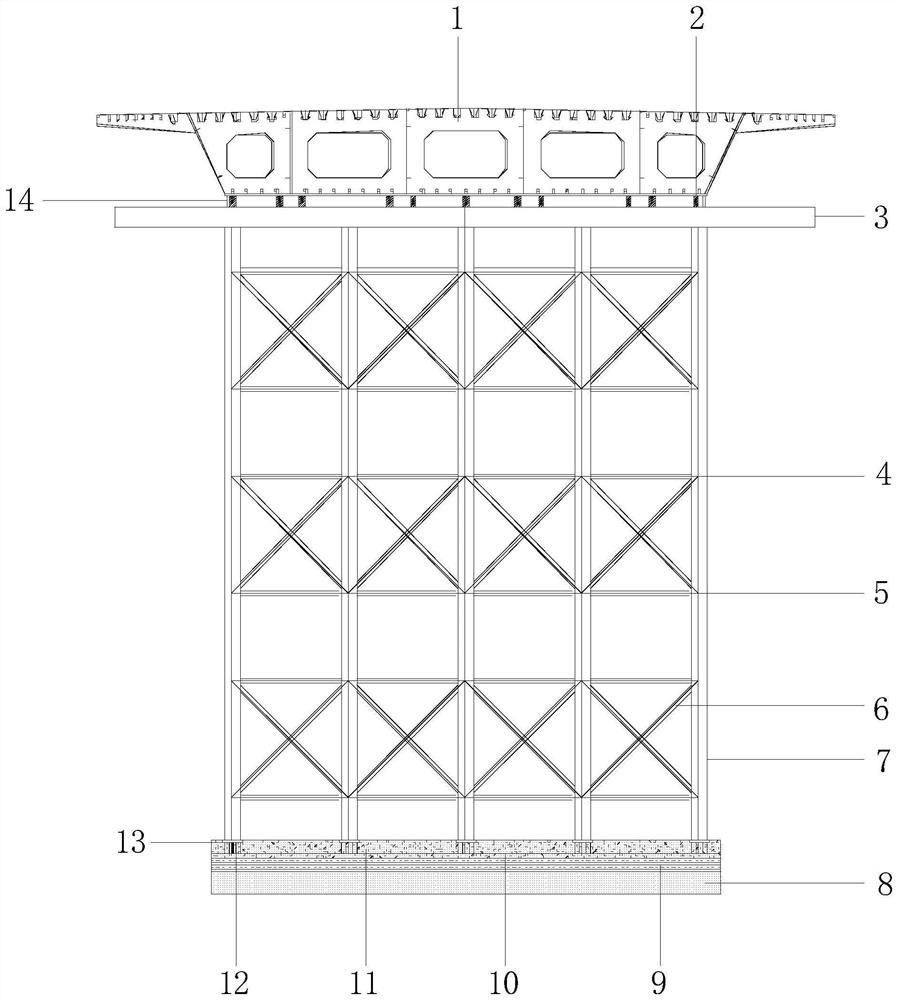

[0041] Step 1. Construction preparation: conduct safety technical assessment for the installation of the upper-span steel box girder 1, carry out hoisting and traffic relief, and simultaneously carry out the prefabrication work of the steel box girder section 24;

[0042] In this step, for the installation of the upper-span steel box girder 1, it is necessary to conduct a safety technical assessment of the upper-span subway under construction, the existing viaduct 27, the bridge pier 28, and the channel structure, so as to carry out hoisting and traffic relief.

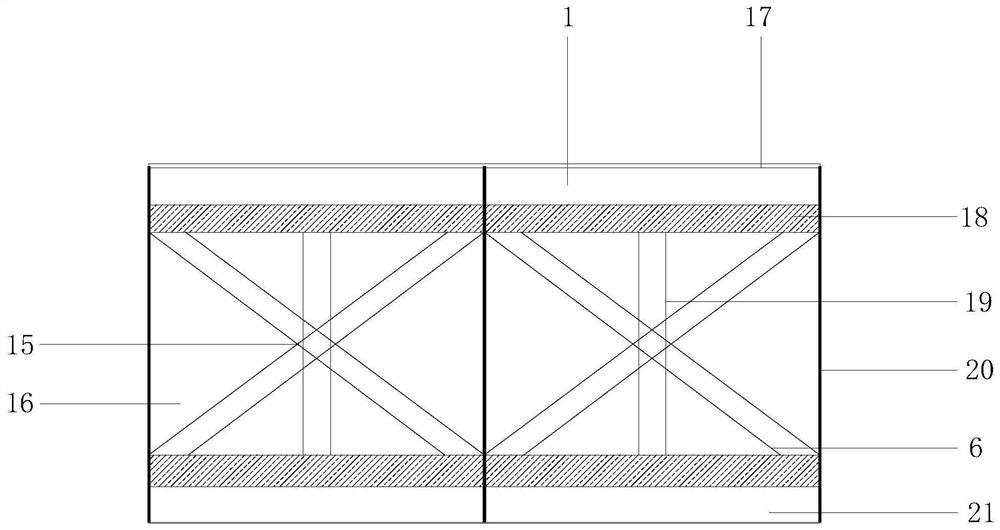

[0043] Step 2, transporting the steel box girder segment 24: transport the prefabricated steel box girder segment 24 to the construction site, and use the steel box girder reinforcement device 15 for reinforcement during the transportation;

[0044] Wherein, the steel box girder segmen...

Embodiment 2

[0062] The large-section steel box girder is constructed by using the construction method of the large-section steel box girder in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com