Textile fabric color fastness detection equipment

A detection equipment, technology of textile fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

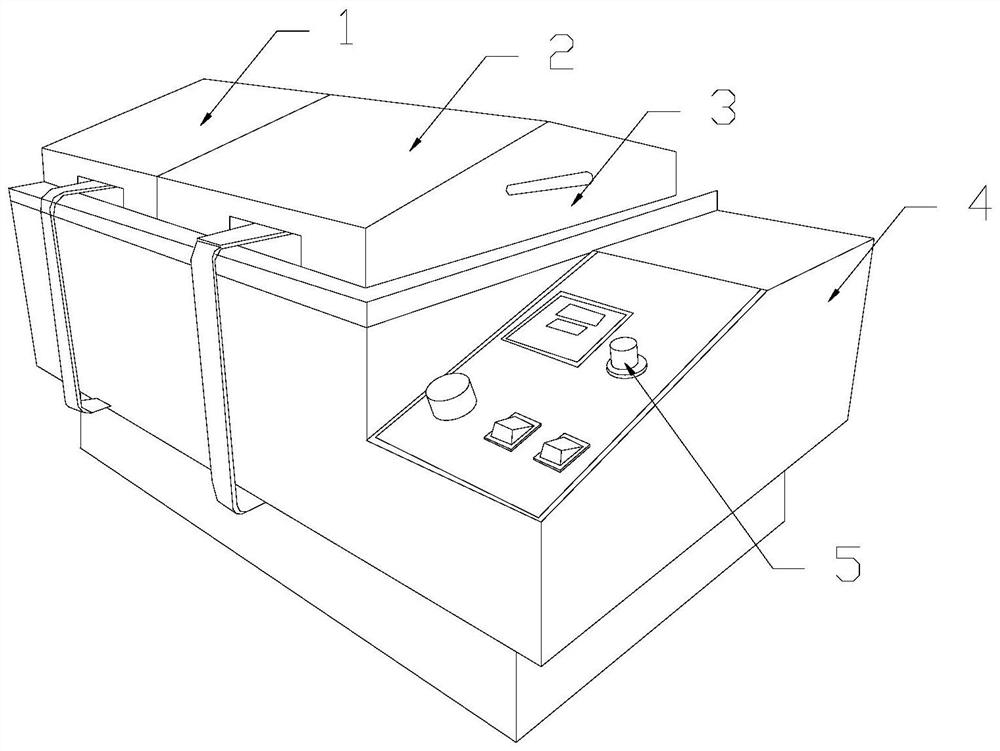

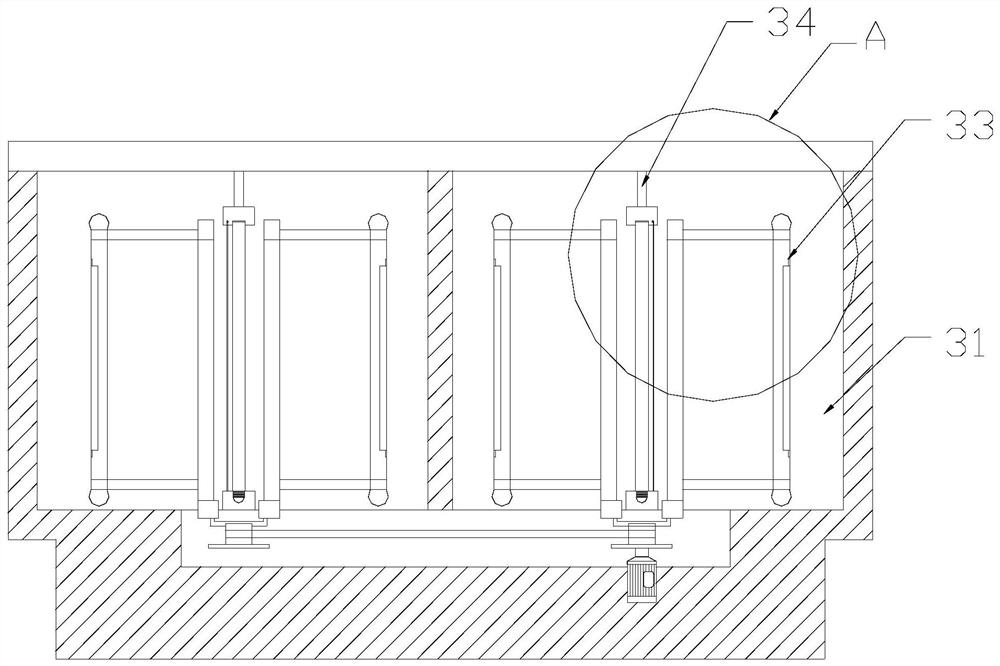

[0026] See Figure 1 - Figure 5 A textile fabric color fastness testing equipment, the present invention provides a textile fabric color fastness testing equipment, the structure comprising a first tank 1 test, the second test box, and the illumination rotating structure 3, the body 4, the control panel 5 one side of the body 4 is mounted a control panel 5, the body 4 is attached to the other end of the first test case 1, case 2 the second test, the second test chamber 2 located in the first tank 1 and the control test between the panel 5, the first test case 1 and the inner box 2 is attached to the second test light rotating structure 3, tank 1 of the first test and the second test tank internal space 2 for the active chamber 31;

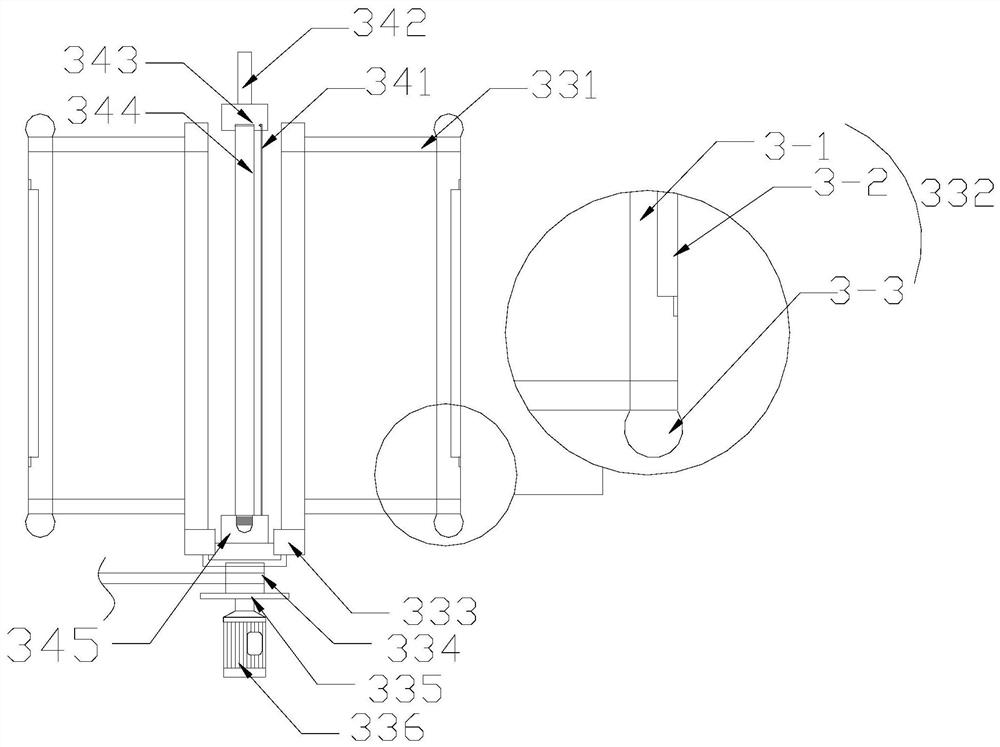

[0027] The rotating structure 3 comprises a light distraction holder 33, the center of the light structure 34, the central light structure 34 is mounted in the center of the active chamber 31, the central structure 34 and the first test light tank 1 or ...

Embodiment 2

[0037] See Figure 1 - Figure 5 A textile fabric color fastness testing equipment, the present invention provides a textile fabric color fastness testing equipment, the structure comprising a first tank 1 test, the second test box, and the illumination rotating structure 3, the body 4, the control panel 5 one side of the body 4 is mounted a control panel 5, the body 4 is attached to the other end of the first test case 1, case 2 the second test, the second test chamber 2 located in the first tank 1 and the control test between the panel 5, the first test case 1 and the inner box 2 is attached to the second test light rotating structure 3, tank 1 of the first test and the second test tank internal space 2 for the active chamber 31;

[0038] The rotating structure 3 comprises a light distraction holder 33, the center of the light structure 34, the central light structure 34 is mounted in the center of the active chamber 31, the central structure 34 and the first test light tank 1 or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com