Rail-mounted inspection robot

An inspection robot and track-type technology, applied in the direction of instruments, two-dimensional position/channel control, non-electric variable control, etc., can solve the problems of increased overall weight, inconvenient maintenance, and reduced use effect, and achieve the degree of automation High, light overall weight, improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

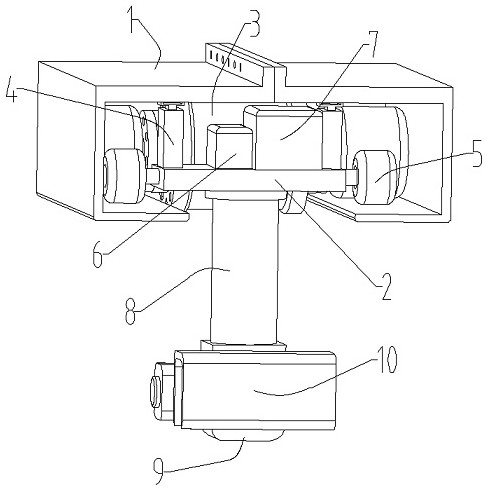

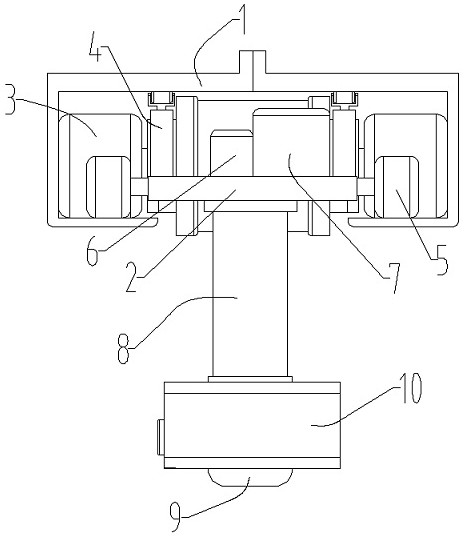

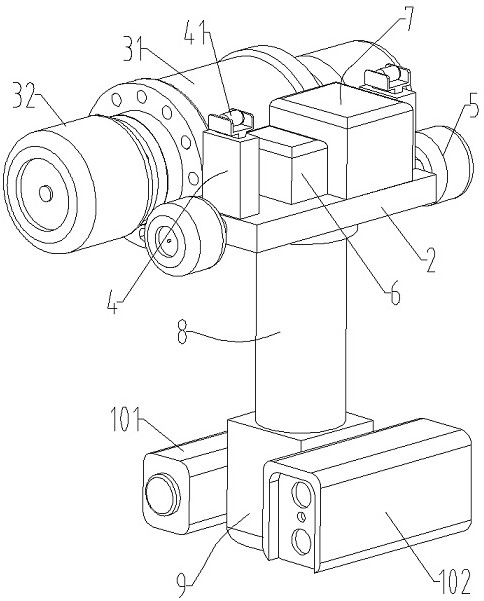

[0037] Example: such as Figure 1-3 As shown, a track-type inspection robot includes a track 1 pre-set according to the travel path, a base plate 2 is arranged inside the track 1, and a mobile joint module 3 for driving the overall movement is set on the base plate 2. The base plate 2 is provided with a pressing wheel device 4 connected to the track 1 for pressing the mobile joint module 3, and a terminal device 10 for monitoring the monitoring area is provided under the substrate 2, and a terminal device 10 is provided on the substrate 2 for A joint module that drives the end device 10 to move and rotate in multiple directions.

[0038] Such as Figure 1-2 with Figure 4 As shown, the track 1 is composed of a first track body 11 and a second track body 12, the first track body 11 and the second track body 12 are arranged oppositely, and the first track body 11 and the second track body 12 They are fixedly connected by connecting flanges 13 to form a whole.

[0039] The in...

Embodiment 2

[0096] Embodiment 2: as Figure 9 As shown, the lifting device 8 in the above-mentioned embodiment 1 can also adopt Figure 9 As shown in the structure, the lifting device 8 includes an installation box 81 , and a multi-stage screw-type bamboo telescoping tube 88 is arranged below the installation box 81 .

[0097] The multi-stage screw-type bamboo telescopic tube 88 includes a plurality of telescopic arms 881 that are movably socketed in sequence.

[0098] The upper ends of the telescopic arms 881 are respectively provided with threaded flanges 882, the threaded flanges 882 are provided with threads, and the bottom of the threaded flanges 882 on the first telescopic arm 881 is provided with a threaded pipe shaft 883.

[0099] The threaded flange 882 of the first section telescopic arm 881 is threadedly connected with the screw rod 884, and the other multi-section telescopic arms 881 are threadedly connected with the threaded pipe shaft 883 through the threaded flange 882.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com